Abstract

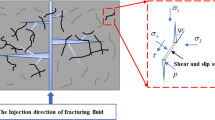

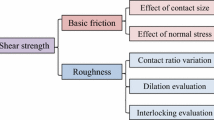

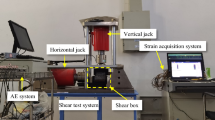

In the drilling and stimulation operations of deep/ultra-deep oil and gas wells, high in situ stress conditions may increase the occurrence probability of rock shear failures. According to Mole-Coulomb laws, the friction coefficient becomes more significant in evaluating borehole instability, faults/natural fractures activation and hydraulic-natural fractures intersection scenarios. This paper proposes a multiscale model to calculate the rock friction coefficients based on the surface properties at different scales. The key parameters of surface properties are obtained from three-dimensional laser scan of friction planes, and the results are verified by the direct shearing and triaxial compression strength tests. For the flat or new-cutting surfaces, the computed basic friction coefficients range of 0.231–0.509, fitting well with the tested values of 0.303–0.437. It also shows that the basic friction coefficients grow in the order of shale, carbonate and tight sandstone, positively associated with the size of the rock sedimentary particles. For the roughness surfaces, the coefficients are computed based on the former basic friction values and the surface asperity dip angles distribution, and the values located in a wide range of 0.541–1.113, also matched well with the measured friction coefficients via direct shearing tests. When the normal stress increase, the rock friction coefficients generally decline, and the values of some shale and dolomite samples can decrease to 0.2, due to the existence of beddings or fracture fillings. The above outcomes may provide useful insights for wellbore instability assessment and hydraulic fracturing optimization.

Similar content being viewed by others

References

Wang, W.; Pang, X.; Chen, Z.; Chen, D.; Zheng, T.; Luo, B.; Yu, R.: Quantitative prediction of oil and gas prospects of the Sinian-Lower Paleozoic in the Sichuan Basin in central China. Energy 174, 861–872 (2019). https://doi.org/10.1016/j.energy.2019.03.018

Gentzis, T.: Review of the hydrocarbon potential of the Steele Shale and Niobrara Formation in Wyoming, USA: A major unconventional resource play? Int. J. Coal Geol. 166, 118–127 (2016). https://doi.org/10.1016/j.coa12016.07.002

Guo, J.; Gou, B.; Qin, N.: An innovative concept on deep carbonate reservoir stimulation: Three-dimensional acid fracturing technology. Nat. Gas. Ind. 40(2), 61–74 (2020). https://doi.org/10.3787/j.issn.1000-0976.2020.02.007

Wen, H.; Chen, M.; Jin, Y.: A chemo-mechanical coupling model of deviated borehole stability in hard brittle shale. Pet. Explor. Dev. 41(6), 748–754 (2014). https://doi.org/10.1016/S1876-3804(14)60099-9

Yan, W.; Ge, H.; Wang, J.: Experimental study of the friction properties and compressive shear failure behaviors of gas shale under the influence of fluids. J. Natural Gas Sci. Eng. 33, 153–161 (2016). https://doi.org/10.1016/j.jngse.2016.04.019

Yu, H.; Taleghani, A.D.; Lian, Z.; Lin, T.: On how asymmetric stimulated rock volume in shales may impact casing integrity. Energy Sci. Eng. 8, 1524–1540 (2020). https://doi.org/10.1002/ese3.610

Chuprakov, D.A.; Zhubayev, A.S.: A variational approach to analyze a natural fault with hydraulic fracture based on the strain energy density criterion. Theoret. Appl. Fract. Mech. 53(3), 221–232 (2010). https://doi.org/10.1016/j.tafmec.2010.06.007

Dahi-Taleghani, A.; Olson, J.E.: Numerical modeling of multistranded-hydraulic-fracture propagation: accounting for the interaction between induced and natural fractures. SPE J. 16(3), 575–581 (2011). https://doi.org/10.2118/124884-PA

Yi, W.; Rao, Q.H.; Luo, S.; Shen, Q.Q.; Li, Z.: A new integral equation method for calculating interacting stress intensity factor of multiple crack-hole problem. Theor. Appl. Fracture Mech. (2020). https://doi.org/10.1016/j.tafmec.2020.102535

Yang, J.; Rong, G.; Hou, D.; Peng, J.; Zhou, C.: Experimental study on peak shear strength criterion for rock joints. Rock Mech. Rock Eng. 49(3), 821–835 (2016). https://doi.org/10.1007/s00603-015-0791-1

Mehrishal, S.; Sharifzadeh, M.; Shahriar, K.: Shear model development of limestone joints with incorporating variations of basic friction coefficient and roughness components during shearing. Rock Mech. Rock Eng. 50(4), 825–855 (2017). https://doi.org/10.1007/s00603-016-1128-4

Yan, X.; You, L.; Kang, Y.: Impact of drilling fluids on friction coefficient of brittle gas shale. Int. J. Rock. Mech. Min. Sci. 106, 144–152 (2018). https://doi.org/10.1016/j.ijrmms.2018.04.026

Scholz, C.H.; Molnar, P.; Johnson, T.: Detailed studies of Jrictional sliding in granite and implications for earthquake mechanism. J Geophys Res 77, 6392–6406 (1972). https://doi.org/10.1029/JB077i032p06392

Barton, N.: The shear strength of rock and rock joints. Int. J. Rock. Mech. Min. 13(9), 255–279 (1976). https://doi.org/10.1016/0148-9062(76)90003-6

Yao, L.; Ma, S.L.: Experimental simulation of coseismic fault sliding-significance, technological methods and research progress of high-velocity frictional experiments. Prog. Geophys. (In Chinese) 28(2), 607–623 (2013). https://doi.org/10.6038/pg20130210

Byerlee, J.D.; Summers, R.: Stable sliding preceding stick-slip on fault surfaces in granite at high pressure. Pure Appl Geophys 113, 63–68 (1975). https://doi.org/10.1007/978-3-0348-5534-1_6

Kulatilake, P.; Shou, G.; Huang, T., et al.: New peak shear strength criteria for anisotropic rock joints. Int J Rock Mech Min Sci Geomech Abs 32(7), 673–697 (1995). https://doi.org/10.1016/0148-9062(95)00022-9

Mehrishal, S.; Sharifzadeh, M.; Shahriar, K.: An experimental study on normal stress and shear rate dependency of basic friction coefficient in dry and wet limestone joints. Rock Mech. Rock Eng. 49(12), 4607–4629 (2016). https://doi.org/10.1007/s00603-016-1073-2

Dieterich, J.H.: Modeling of rock friction 1. Experimental results and constitutive equations. J. Geophys. Res. 84(B5), 2161–2168 (1979). https://doi.org/10.1029/JB084iB05p02161

Marone, C.; Hobbs, B.E.; Ord, A.: Coulomb constitutive laws for friction: Contrasts in frictional behavior for distributed and localized shear. Pure Appl. Geophys. 139(2), 195–214 (1992). https://doi.org/10.1007/BF00876327

Wang, G.; Zhang, X.; Jiang, Y.: Rate-dependent mechanical behavior of rough rock joints. Int. J. Rock Mech. Min. Sci. 83, 231–240 (2016). https://doi.org/10.1016/j.ijrmms.2015.10.013

Jang, H.; Zhang, Q.; Kang, S.: Determination of the basic friction angle of rock surfaces by tilt tests. Rock Mech. Rock Eng. 51(4), 989–1004 (2018). https://doi.org/10.1007/s00603-017-1388-7

Barton, N.: Review of a new sheer strength criterion for rock joints. Eogno. Geol. 7, 287–332 (1973). https://doi.org/10.1016/0013-7952(73)90013-6

Barton, N.; Choubey, V.: The shear strength of rock joints in theory and practice. Rock Mech. 10(1–2), 1–54 (1977). https://doi.org/10.1007/BF01261801

Reeves, M.J.: Rock surface roughness and frictional strength. Int J Rock Mech Min Sci 22(6), 429–442 (1985). https://doi.org/10.1016/0148-9062(85)90007-5

Tate, N.J.: Estimating the fractal dimension of synthetic topographic surfaces. Comput. Geosci. 24, 325–334 (1998). https://doi.org/10.1016/S0098-3004(97)00119-2

Rasouli, V.; Harrison, J.P.: Assessment of rock fracture surface roughness using Riemannian statistics of linear profiles. Int J Rock Mech Min Sci 47, 940–948 (2010). https://doi.org/10.1016/j.ijrmms.2010.05.013

Park, J.W.; Song, J.J.: Numerical method for the determination of contact areas of a rock joint under normal and shear loads. Int J Rock Mech Min Sci 58, 8–22 (2013). https://doi.org/10.1016/j.ijrmms.2012.10.001

Grasselli, G.; Egger, P.: Constitutive law for the shear strength of rock joints based on three-dimensional surface parameters. Int. J. Rock Mech. Min. Sci. 40, 25–40 (2003). https://doi.org/10.1016/S1365-1609(02)00101-6

Li, Y.; Wu, W.; Li, B.: An analytical model for two-order asperity degradation of rock joints under constant normal stiffness conditions. Rock Mech. Rock Eng. 51, 1431–1445 (2018). https://doi.org/10.1007/s00603-018-1405-5

Guan, C.; Qi, J.; Qiu, N.: Three levels friction coefficients of cracks and their influencing factors—taking the sandstone (particle packing layers) as an example. Appl. Math. Mech. 34(2), 209–216 (2013). https://doi.org/10.3879/j.issn.1000-0887.2013.02.011

Park, J.W.; Lee, Y.K.; Song, J.J.; Choi, B.H.: A constitutive model for shear behavior of rock joints based on three-dimensional quantification of joint roughness. Rock Mech Rock Eng 46, 1513–1537 (2013). https://doi.org/10.1007/s00603-012-0365-4

Horn, H.M.; Deere, D.U.: Frictional characteristics of minerals. Geotechnique 12(4), 319–335 (1962). https://doi.org/10.1680/geot.1962.12.4.319

Bobko, C.P.; Gathier, B.; Ortega, J.A.: The nanogranular origin of friction and cohesion in shale—A strength homogenization approach to interpretation of nanoindentation results. Int. J. Numer. Anal. Meth. Geomech. 35(17), 1854–1876 (2011). https://doi.org/10.1002/nag.984

Popov, V.L.: Contact Mechanics and Friction: Physical Principles and Applications (2nd edition). Springer, Berlin Heidelberg, Berlin (2010) https://doi.org/10.1007/978-3-642-10803-7

Bowden, F.P.; Tabor, D.: The Friction and Lubrication of Solids, Vol. 1. Oxford University Press, Oxford (2001) https://doi.org/10.1119/1.1933017

Guan, C.Y.; Qi, J.F.; Qiu, N.S.; Zhao, G.C.; Yang, Q.; Bai, X.D.: Macroscopic young’s elastic modulus model of particle packing rock layers. Open J. Geol. 2(3), 198–202 (2012). https://doi.org/10.4236/ojg.2012.23020

Tatone, B.S.; Grasselli, G.: A method to evaluate the three dimensional roughness of fracture surfaces in brittle geomaterials. Rev. Sci. Instrum. 80(12), 181–196 (2009). https://doi.org/10.1063/1.3266964

Tian, Y.; Liu, Q.; Liu, D.: Updates to Grasselli’s peak shear strength model. Rock Mech. Rock Eng. 51(7), 2115–2133 (2018). https://doi.org/10.1007/s00603-018-1469-2

Chen, X.; Zeng, Y.; Sun, H.: A new model of the initial dilatancy angle of rock joints based on Grasselli’s morphological parameters. Chin. J. Rock Mech. Eng. 38(1), 132–152 (2019). https://doi.org/10.13722/j.cnki.jrme.2018.0603

Tang, Z.C.; Xia, C.; Song, Y.L.: Discussion about grasselli’s peak shear strength criterion for rock joints. Chin. J. Rock Mech. Eng. 31(2), 356–364 (2012)

Xia, C.C.; Tang, Z.C.; Xiao, W.M.: New peak shear strength criterion of rock joints based on quantified surface description. Rock Mech. Rock Eng. 47(2), 387–400 (2014). https://doi.org/10.1007/s00603-013-0395-6

Han, R.; Hirose, T.; Shimamoto, T.: Strong velocity weakening and powder lubrication of simulated carbonate faults at seismic slip rates. J. Geophys. Res. 115(B03412), 1–23 (2010). https://doi.org/10.1029/2008JB006136

Han, W.; Kang, T.; Wang, D.: Experimental studies on influence of mineral composition on frictional characteristics of polished rocks. Chinese J. Geotech. Eng. 33(8), 1211–1214 (2011). https://doi.org/10.1631/jzus.B1000185

Grasselli, G.: Manuel rocha medal recipient shear strength of rock joints based on quantified surface description. Rock Mech. Rock Eng. 39(4), 295–314 (2006). https://doi.org/10.1007/s00603-006-0100-0

Ban, L.; Qi, C.; Li, X.: A 3D quantified surface description for rock joint based on the real contact asperities. J. China Coal Soc. 45(12), 4052–4061 (2020). https://doi.org/10.13225/j.cnki.jccs.2019.1549

Shi, X.; Cheng, Y.; Jiang, S.; Cai, D.; Zhang, T.: Experimental study of microstructure and rock properties of shale samples. Chin. J. Rock Mech. Eng. 33(2), 3439–3446 (2014). https://doi.org/10.13722/j.cnki.jrme.2014.s2.007

An, M.; Zhang, F.; Elsworth, D.; Xu, Z.; Chen, Z.; Zhang, L.: Friction of Longmaxi shale gouges and implications for seismicity during hydraulic fracturing. J. Geophys. Res. Solid Earth 125, e2020JB019885 (2020). https://doi.org/10.1029/2020JB019885

Guo, J.; Guo, B.; Chen, Y.; Luo, T.: An unloading strength criterion of rock considering end-friction effect. Chin. J. Rock Mech. Eng. 38(7), 1307–1318 (2019). https://doi.org/10.13722/j.cnki.jrme.2018.1433

Jiang, W.: Formation Collapse Pressure Calculation Method Based on Mohr Circular Envelope. Southwest Petroleum University, Chengdu (2019) https://doi.org/10.27420/d.cnki.gxsyc.2019.000556

Gao, Y.: The Rock Mechanical Characters and Fractures Stress Sensitivity Research of Dense Reservoir in West Sichuan Basin. Chengdu University of Technology, Chengdu (2008)

Niemeijer, A.; Di Toro, G.; Nielsen, S.; Di Felice, F.: Frictional melting of gabbro under extreme experimental conditions of normal stress, acceleration, and sliding velocity. J. Geophys. Res. 116, B07404 (2011). https://doi.org/10.1029/2010JB008181

Hu, W.; Huang, R.; McSaveney, M.; Zhang, X.; Yao, L.; Shimamoto, T.: Mineral changes quantify frictional heating during a large low-friction landslide. Geology 46(3), 223–226 (2018). https://doi.org/10.1130/G39662.1

Yang, B.; Kang, Y.; You, L.; Li, X.; Chen, Q.: Measurement of the surface diffusion coefficient for adsorbed gas in the fine mesopores and micropores of shale organic matter. Fuel 181, 793–804 (2016). https://doi.org/10.1016/j.fuel.2016.05.069

Acknowledgments

The authors are thankful to the Open Fund of the State Key Laboratory of Shale Oil and Gas Enrichment Mechanisms and Effective Development (No. 3580000-22-ZC0607-0030), the National Natural Science Youth Foundation of China (No. 52104003), the Joint Fund of the National Natural Science Foundation of China (Nos. U19A2097 and U19B6003), the Natural Science Foundation of Guangdong Province (No. 2019A1515012235) and the Science and Technology Planning Project of Sichuan Province (Nos. 2021YJ0359 and 2020JDTD0017) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, D., Yang, B., Jin, J. et al. Friction Coefficients Calculation via Surface Roughness Characterization for Tight Sedimentary Rocks. Arab J Sci Eng 48, 9287–9298 (2023). https://doi.org/10.1007/s13369-022-07314-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07314-2