Abstract

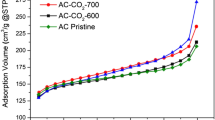

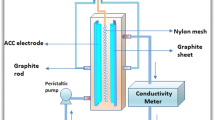

Capacitive deionization (CDI) is a simple, cost-efficient, and environmentally friendly method for brackish water desalination, and CDI technology also refers to heavy metal removal through the non-Faraday-process. In order to develop the highly electro-adsorptive electrode for heavy metal electrosorption via CDI process, a combination of biomass-derived activated carbon (AC) and nano-carbonaceous materials have been considered as a sustainable approach. In this study, the composite coconut-shell-derived AC@CNTs electrode with low CNTs content (1 wt%) was utilized for Cu(II) and Zn(II) removal. The surface properties of pristine AC and KOH-activated AC with nitrogen adsorption technique (BET) and scanning electron microscopy (SEM) are characterized. As calculated from BET measurements, surface area are 581 m2/g, 560 m2/g, and 552 m2/g, corresponding to AC-KOH-2@CNTs, AC-KOH-4@CNTs, and AC-KOH-6@CNTs. After KOH activation, a specific capacitance of AC-KOH-2@CNTs is significantly increased up to 133.7 F/g in comparison with 78.0 F/g of pristine AC. Furthermore, in the Cu(II) and Zn(II) removal performance, AC-KOH-2@CNTs achieved a significant average salt adsorption rate of 29.87 mg/g min and 25.27 mg/g min with a high salt adsorption (SAC) of 7.31 mg/g and 12.55 mg/g at the operation voltage of 1.2 V in 200 ppm CuSO4 solution and 200 ppm ZnSO4 solution, respectively.

Similar content being viewed by others

References

Porada, S.; Zhao, R.; van der Wal, A., et al.: Review on the science and technology of water desalination by capacitive deionization. Prog. Mater. Sci. 58, 1388–1442 (2013). https://doi.org/10.1016/j.pmatsci.2013.03.005

Anderson, M.A.; Cudero, A.L.; Palma, J.: Capacitive deionization as an electrochemical means of saving energy and delivering clean water. Comparison to present desalination practices: will it compete? Electrochim. Acta 55, 3845–3856 (2010). https://doi.org/10.1016/j.electacta.2010.02.012

Mekonnen, M.M.; Hoekstra, A.Y.: Four billion people facing severe water scarcity. Sci. Adv. 2, e1500323 (2016). https://doi.org/10.1126/sciadv.1500323

Oren, Y.: Capacitive deionization (CDI) for desalination and water treatment—past, present and future (a review). Desalination 228, 10–29 (2008). https://doi.org/10.1016/j.desal.2007.08.005

Huang, Z.-H.; Yang, Z.; Kang, F.; Inagaki, M.: Carbon electrodes for capacitive deionization. J. Mater. Chem. A 5, 470–496 (2017). https://doi.org/10.1039/C6TA06733F

Anis, S.F.; Hashaikeh, R.; Hilal, N.: Functional materials in desalination: a review. Desalination 468, 114077 (2019). https://doi.org/10.1016/j.desal.2019.114077

Evans, S.F.; Ivancevic, M.R.; Wilson, D.J., et al.: Carbon polyaniline capacitive deionization electrodes with stable cycle life. Desalination 464, 25–32 (2019). https://doi.org/10.1016/j.desal.2019.04.002

Tian, S.; Wu, J.; Zhang, X., et al.: Capacitive deionization with nitrogen-doped highly ordered mesoporous carbon electrodes. Chem. Eng. J. 380, 122514 (2020). https://doi.org/10.1016/j.cej.2019.122514

Deng, D.; Luhasile, M.K.; Li, H., et al.: A novel layered activated carbon with rapid ion transport through chemical activation of chestnut inner shell for capacitive deionization. Desalination 531, 115685 (2022). https://doi.org/10.1016/j.desal.2022.115685

Le, V.H.; Huynh, L.T.N.; Tran, T.N., et al.: Comparative desalination performance of activated carbon from coconut shell waste/carbon nanotubes composite in batch mode and single-pass mode. J. Appl. Electrochem. 51, 1313–1322 (2021). https://doi.org/10.1007/s10800-021-01575-9

Kim, T.; Gorski, C.A.; Logan, B.E.: Low energy desalination using battery electrode deionization. Environ. Sci. Technol. Lett. 4, 444–449 (2017). https://doi.org/10.1021/acs.estlett.7b00392

Fan, C.-S.; Tseng, S.-C.; Li, K.-C.; Hou, C.-H.: Electro-removal of arsenic(III) and arsenic(V) from aqueous solutions by capacitive deionization. J. Hazard Mater. 312, 208–215 (2016). https://doi.org/10.1016/j.jhazmat.2016.03.055

Ren, Q.; Wang, G.; Wu, T., et al.: Calcined MgAl-layered double hydroxide/graphene hybrids for capacitive deionization. Ind. Eng. Chem. Res. 57, 6417–6425 (2018). https://doi.org/10.1021/acs.iecr.7b04983

Vafakhah, S.; Guo, L.; Sriramulu, D., et al.: Efficient sodium-ion intercalation into the freestanding Prussian blue/graphene aerogel anode in a hybrid capacitive deionization system. ACS Appl. Mater. Interfaces 11, 5989–5998 (2019). https://doi.org/10.1021/acsami.8b18746

Liu, Y.; Gao, X.; Zhang, L., et al.: Mn2O3 nanoflower decorated electrospun carbon nanofibers for efficient hybrid capacitive deionization. Desalination 494, 114665 (2020). https://doi.org/10.1016/j.desal.2020.114665

Han, J.; Yan, T.; Shen, J., et al.: Capacitive deionization of saline water by using MoS2–graphene hybrid electrodes with high volumetric adsorption capacity. Environ. Sci. Technol. 53, 12668–12676 (2019). https://doi.org/10.1021/acs.est.9b04274

Tan, W.; Gao, T.; Wang, Y.: Influence of surface potential on the capacitive performance of the TiO2 thin-film electrode with different crystalline forms. Langmuir 36, 3836–3842 (2020). https://doi.org/10.1021/acs.langmuir.0c00663

Chen, Z.; Zhang, H.; Wu, C., et al.: A study of electrosorption selectivity of anions by activated carbon electrodes in capacitive deionization. Desalination 369, 46–50 (2015). https://doi.org/10.1016/j.desal.2015.04.022

Huynh, L.T.N.; Pham, T.N.; Nguyen, T.H., et al.: Coconut shell-derived activated carbon and carbon nanotubes composite: a promising candidate for capacitive deionization electrode. Synth. Met. 265, 116415 (2020). https://doi.org/10.1016/j.synthmet.2020.116415

Xu, P.; Drewes, J.E.; Heil, D.; Wang, G.: Treatment of brackish produced water using carbon aerogel-based capacitive deionization technology. Water Res. 42, 2605–2617 (2008). https://doi.org/10.1016/j.watres.2008.01.011

Yan, C.; Zou, L.; Short, R.: Single-walled carbon nanotubes and polyaniline composites for capacitive deionization. Desalination 290, 125–129 (2012). https://doi.org/10.1016/j.desal.2012.01.017

Moronshing, M.; Subramaniam, C.: Scalable approach to highly efficient and rapid capacitive deionization with CNT-thread as electrodes. ACS Appl. Mater. Interfaces 9, 39907–39915 (2017). https://doi.org/10.1021/acsami.7b11866

Dong, Q.; Wang, G.; Qian, B., et al.: Electrospun composites made of reduced graphene oxide and activated carbon nanofibers for capacitive deionization. Electrochim. Acta 137, 388–394 (2014). https://doi.org/10.1016/j.electacta.2014.06.067

Tsouris, C.; Mayes, R.; Kiggans, J., et al.: Mesoporous carbon for capacitive deionization of saline water. Environ. Sci. Technol. 45, 10243–10249 (2011). https://doi.org/10.1021/es201551e

Wang, H.; Shi, L.; Yan, T., et al.: Design of graphene-coated hollow mesoporous carbon spheres as high performance electrodes for capacitive deionization. J. Mater. Chem. A 2, 4739–4750 (2014). https://doi.org/10.1039/C3TA15152B

Wimalasiri, Y.; Zou, L.: Carbon nanotube/graphene composite for enhanced capacitive deionization performance. Carbon 59, 464–471 (2013). https://doi.org/10.1016/j.carbon.2013.03.040

Foo, K.Y.; Hameed, B.H.: A short review of activated carbon assisted electrosorption process: an overview, current stage and future prospects. J. Hazard. Mater. 170, 552–559 (2009). https://doi.org/10.1016/j.jhazmat.2009.05.057

Daer, S.; Kharraz, J.; Giwa, A.; Hasan, S.W.: Recent applications of nanomaterials in water desalination: a critical review and future opportunities. Desalination 367, 37–48 (2015). https://doi.org/10.1016/j.desal.2015.03.030

Thamilselvan, A.; Nesaraj, A.S.; Noel, M.: Review on carbon-based electrode materials for application in capacitive deionization process. Int. J. Environ. Sci. Technol. 13, 2961–2976 (2016). https://doi.org/10.1007/s13762-016-1061-9

Zhang, X.; Yang, F.; Ma, J.; Liang, P.: Effective removal and selective capture of copper from salty solution in flow electrode capacitive deionization. Environ. Sci. Water Res. Technol. 6, 341–350 (2020). https://doi.org/10.1039/C9EW00467J

Huang, Z.; Lu, L.; Cai, Z.; Ren, Z.J.: Individual and competitive removal of heavy metals using capacitive deionization. J. Hazard. Mater. 302, 323–331 (2016). https://doi.org/10.1016/j.jhazmat.2015.09.064

Gaikwad, M.S.; Balomajumder, C.: Tea waste biomass activated carbon electrode for simultaneous removal of Cr(VI) and fluoride by capacitive deionization. Chemosphere 184, 1141–1149 (2017). https://doi.org/10.1016/j.chemosphere.2017.06.074

You, S.-M.; Tasi, C.-K.; Millet, P.; Doong, R.-A.: Electrochemically capacitive deionization of copper (II) using 3D hierarchically reduced graphene oxide architectures. Sep. Purif. Technol. 251, 117368 (2020). https://doi.org/10.1016/j.seppur.2020.117368

Chen, R.; Sheehan, T.; Ng, J.L., et al.: Capacitive deionization and electrosorption for heavy metal removal. Environ. Sci. Water Res. Technol. 6, 258–282 (2020). https://doi.org/10.1039/C9EW00945K

Cao, Z.; Zhang, C.; Yang, Z., et al.: Preparation of carbon aerogel electrode for electrosorption of copper ions in aqueous solution. Materials 12, 1864 (2019). https://doi.org/10.3390/ma12111864

Huang, C.-C.; Siao, S.-F.: Removal of copper ions from an aqueous solution containing a chelating agent by electrosorption on mesoporous carbon electrodes. J. Taiwan Inst. Chem. Eng. 85, 29–39 (2018). https://doi.org/10.1016/j.jtice.2018.02.005

Huang, C.-C.; Su, Y.-J.: Removal of copper ions from wastewater by adsorption/electrosorption on modified activated carbon cloths. J. Hazard. Mater. 175, 477–483 (2010). https://doi.org/10.1016/j.jhazmat.2009.10.030

Huang, S.-Y.; Fan, C.-S.; Hou, C.-H.: Electro-enhanced removal of copper ions from aqueous solutions by capacitive deionization. J. Hazard. Mater. 278, 8–15 (2014). https://doi.org/10.1016/j.jhazmat.2014.05.074

Tang, W.; Wang, X.; Zeng, G., et al.: Electro-assisted adsorption of Zn(II) on activated carbon cloth in batch-flow mode: experimental and theoretical investigations. Environ. Sci. Technol. 53, 2670–2678 (2019). https://doi.org/10.1021/acs.est.8b05909

Sesuk, T.; Tammawat, P.; Jivaganont, P., et al.: Activated carbon derived from coconut coir pith as high performance supercapacitor electrode material. J. Energy Storage 25, 100910 (2019). https://doi.org/10.1016/j.est.2019.100910

Guo, S.; Peng, J.; Li, W., et al.: Effects of CO2 activation on porous structures of coconut shell-based activated carbons. Appl. Surf. Sci. 255, 8443–8449 (2009). https://doi.org/10.1016/j.apsusc.2009.05.150

Nguyen, T.T.; Huynh, L.T.N.; Pham, T.N., et al.: Enhanced capacitive deionization performance of activated carbon derived from coconut shell electrodes with low content carbon nanotubes–graphene synergistic hybrid additive. Mater. Lett. 292, 129652 (2021). https://doi.org/10.1016/j.matlet.2021.129652

Ngo, H.L.; Nguyen, N.T.; Ho, T.T.N., et al.: A low-cost and eco-friendly fabrication of an MCDI-utilized PVA/SSA/GA cation exchange membrane. Green Process. Synth. 11, 563–571 (2022). https://doi.org/10.1515/gps-2022-0056

Reddy, K.S.K.; Al Shoaibi, A.; Srinivasakannan, C.: A comparison of microstructure and adsorption characteristics of activated carbons by CO2 and H3PO4 activation from date palm pits. New Carbon Mater. 27, 344–351 (2012). https://doi.org/10.1016/S1872-5805(12)60020-1

Allwar, A.; Noor, A.M.; Nawi, M.A.M.: Preparation and characterization of microporous activated carbon from oil palm shell by physical activation using purified nitrogen. EKSAKTA J. Sci. Data Anal. 12 (2011)

Wenzhong, S.; Zhijie, L.; Yihong, L.: Surface chemical functional groups modification of porous carbon. Recent Patents Chem. Eng. 1, 27–40 (2007)

Sufiani, O.; Elisadiki, J.; Machunda, R.L.; Jande, Y.A.C.: Modification strategies to enhance electrosorption performance of activated carbon electrodes for capacitive deionization applications. J. Electroanal. Chem. 848, 113328 (2019). https://doi.org/10.1016/j.jelechem.2019.113328

Şahin, Ö.; Yardim, Y.; Baytar, O.; Saka, C.: Enhanced electrochemical double-layer capacitive performance with CO2 plasma treatment on activated carbon prepared from pyrolysis of pistachio shells. Int. J. Hydrog. Energy 45, 8843–8852 (2020). https://doi.org/10.1016/j.ijhydene.2020.01.128

Lee, B.; Park, N.; Kang, K.S., et al.: Enhanced capacitive deionization by dispersion of CNTs in activated carbon electrode. ACS Sustain. Chem. Eng. 6, 1572–1579 (2018). https://doi.org/10.1021/acssuschemeng.7b01750

Kim, T.; Yoon, J.: CDI Ragone plot as a functional tool to evaluate desalination performance in capacitive deionization. RSC Adv. 5, 1456–1461 (2015). https://doi.org/10.1039/C4RA11257A

Goldin, M.M.; Volkov, A.G.; Namychkin, D.N.: Adsorption of copper, silver, and zinc cations on polarized activated carbons. J. Electrochem. Soc. 152, E167 (2005). https://doi.org/10.1149/1.1874712

Acknowledgments

This research is funded by Vietnam National University, Ho Chi Minh City (VNU-HCM) under Grant No. 562-2020-18-06.

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huynh, L.T.N., Nguyen, H.A., Pham, H.V. et al. Electrosorption of Cu(II) and Zn(II) in Capacitive Deionization by KOH Activation Coconut-Shell Activated Carbon. Arab J Sci Eng 48, 551–560 (2023). https://doi.org/10.1007/s13369-022-07305-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07305-3