Abstract

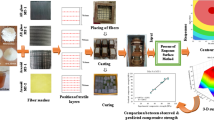

In this study, sustainable polyurethane-based polymer rubber concrete (PU-based PRC) was prepared using crumb rubber (CR) and ground glass fiber (GGF) particles for road pavement and runway repair. Moreover, tensile characteristics and failure mode of rigid GGF/PU grout materials were investigated. Response surface methodology/central composite design tool was employed to analyze the responses’ compressive strength, flexural and relative density. CR and GGF particles were used as input variables. The result indicates that the combined effect of CR and GGF particles improved the mechanical properties of PU-based PRC specimens, and a reduction in mechanical properties was observed in samples blended with high CR content as only admixture material. On the other hand, the tensile characteristic of GGF/PUgrout material decreases with an increase in GGF content. The developed models have successfully predicted the mechanical behavior and relative density of PU-based PRC using CR and GGF particles as the independent variable with high accuracy. The optimized PU-based PRC mix could be achieved by partially replacing 13.47%CR and the addition of 3%GGF. Moreover, scanning electron microscopy revealed that the reinforcing mechanism of GGF particles had bridged the cracks and voids.

Similar content being viewed by others

References

F Giussani F Mola 2012 Durable concrete pavements: the reconstruction of runway head 36R of Milano Linate International Airport Constr. Build. Mater. 34 352 361 https://doi.org/10.1016/j.conbuildmat.2012.02.013

X Hou F Xiao J Wang S Amirkhanian 2018 Identification of asphalt aging characterization by spectrophotometry technique Fuel 226 230 239 https://doi.org/10.1016/j.fuel.2018.04.030

JW Bull CH Woodford 1997 Design of precast concrete pavement units for rapid maintenance of runways Comput. Struct. 64 857 864 https://doi.org/10.1016/S0045-7949(96)00431-2

H Huang H Pang J Huang H Zhao B Liao 2020 Synthesis and characterization of ground glass fiber reinforced polyurethane-based polymer concrete as a cementitious runway repair material Constr. Build. Mater. 242 117221https://doi.org/10.1016/j.conbuildmat.2019.117221

I-T Roh K-C Jung S-H Chang Y-H Cho 2015 Characterization of compliant polymer concretes for rapid repair of runways Constr. Build. Mater. 78 77 84 https://doi.org/10.1016/j.conbuildmat.2014.12.121

M Li M Du F Wang B Xue C Zhang H Fang 2020 Study on the mechanical properties of polyurethane (PU) grouting material of different geometric sizes under uniaxial compression Constr. Build. Mater. 259 119797https://doi.org/10.1016/j.conbuildmat.2020.119797

Y Liu Z Xi J Cai H Xie 2017 Laboratory investigation of the properties of epoxy asphalt rubber (EAR) Mater. Struct. 50 219 https://doi.org/10.1617/s11527-017-1089-4

Z-X Hu X-M Hu W-M Cheng Y-Y Zhao M-Y Wu 2018 Performance optimization of one-component polyurethane healing agent for self-healing concrete Constr. Build. Mater. 179 151 159 https://doi.org/10.1016/j.conbuildmat.2018.05.199

W Jiang H Zhu SI Haruna B Zhao J Shao Y Yu 2021 Effect of crumb rubber powder on mechanical properties and pore structure of polyurethane-based polymer mortar for repair Constr. Build. Mater. 309 125169https://doi.org/10.1016/j.conbuildmat.2021.125169

Ibrahim Haruna, S.; Zhu, H.; Jiang, W.; Shao, J.: Evaluation of impact resistance properties of polyurethane-based polymer concrete for the repair of runway subjected to repeated drop-weight impact test. Constr. Build. Mater. 309, 125152 (2021). Doi: https://doi.org/10.1016/j.conbuildmat.2021.125152

K Zhang Q Sun 2018 The use of Wire Mesh-Polyurethane Cement (WM-PUC) composite to strengthen RC T-beams under flexure J. Build. Eng. 15 122 136 https://doi.org/10.1016/j.jobe.2017.11.008

A Kwiecień 2014 Shear bond of composites-to-brick applied with highly deformable, in relation to resin epoxy, interface materials Mater. Struct. 47 2005 2020 https://doi.org/10.1617/s11527-014-0363-y

A Kwiecień G Felice de DV Oliveira B Zając A Bellini S Santis De B Ghiassi GP Lignola PB Lourenço C Mazzotti A Prota 2016 Repair of composite-to-masonry bond using flexible matrix Mater. Struct. 49 2563 2580 https://doi.org/10.1617/s11527-015-0668-5

DK Chattopadhyay KVSN Raju 2007 Structural engineering of polyurethane coatings for high performance applications Prog. Polym. Sci. 32 352 418 https://doi.org/10.1016/j.progpolymsci.2006.05.003

M Grujicic B Pandurangan T He BA Cheeseman C-F Yen CL Randow 2010 Computational investigation of impact energy absorption capability of polyurea coatings via deformation-induced glass transition Mater. Sci. Eng. A. 527 7741 7751 https://doi.org/10.1016/j.msea.2010.08.042

A Mostafa K Shankar EV Morozov 2015 Behaviour of PU-foam/glass-fibre composite sandwich panels under flexural static load Mater. Struct. 48 1545 1559 https://doi.org/10.1617/s11527-014-0253-3

V Carrera AA Cuadri M García-Morales P Partal 2015 The development of polyurethane modified bitumen emulsions for cold mix applications Mater. Struct. 48 3407 3414 https://doi.org/10.1617/s11527-014-0408-2

A Turatsinze S Bonnet J-L Granju 2007 Potential of rubber aggregates to modify properties of cement based-mortars: improvement in cracking shrinkage resistance Constr. Build. Mater. 21 176 181 https://doi.org/10.1016/j.conbuildmat.2005.06.036

BS Thomas RC Gupta P Mehra S Kumar 2015 Performance of high strength rubberized concrete in aggressive environment Constr. Build. Mater. 83 320 326 https://doi.org/10.1016/j.conbuildmat.2015.03.012

Al-Tayeb, M.M.; Abu Bakar, B.H.; Ismail, H.; Akil, H.M.: Effect of partial replacement of sand by recycled fine crumb rubber on the performance of hybrid rubberized-normal concrete under impact load: Experiment and simulation. J. Clean. Prod. 59, 284–289 (2013). Doi: https://doi.org/10.1016/j.jclepro.2013.04.026.

AG Cachaço MD Afonso ML Pinto 2013 New applications for foam composites of polyurethane and recycled rubber J. Appl. Polym. Sci. 129 2873 2881 https://doi.org/10.1002/app.38962

Z Hong L Bo H Guangsu H Jia 2007 A novel composite sound absorber with recycled rubber particles J. Sound Vib. 304 400 406 https://doi.org/10.1016/j.jsv.2007.02.024

P Król B Król 2012 Surface free energy of polyurethane coatings with improved hydrophobicity Colloid Polym. Sci. 290 879 893 https://doi.org/10.1007/s00396-012-2598-x

Ł Piszczyk A Hejna K Formela M Danowska M Strankowski 2015 Effect of ground tire rubber on structural, mechanical and thermal properties of flexible polyurethane foams Iran. Polym. J. 24 75 84 https://doi.org/10.1007/s13726-014-0301-4

WS Chow YP Yap 2008 Optimization of process variables on flexural properties of epoxy/organo-montmorillonite nanocomposite by response surface methodology Express Polym. Lett. 2 2 11

Adamu, M.; Ayeni, K.O.; Haruna, S.I.; Ibrahim Mansour, Y.E.H.; Haruna, S.: Durability performance of pervious concrete containing rice husk ash and calcium carbide: a response surface methodology approach. Case Stud. Constr. Mater. 14: e00547 (2021). Doi: https://doi.org/10.1016/j.cscm.2021.e00547

M Adamu SI Haruna YE Ibrahim H Alanazi 2021 Investigating the properties of roller-compacted rubberized concrete modified with nanosilica using response surface methodology Innov. Infrastruct. Solut. 7 119 https://doi.org/10.1007/s41062-021-00717-4

M Adamu SI Haruna YE Ibrahim H Alanazi 2022 Investigating the properties of roller-compacted rubberized concrete modified with nanosilica using response surface methodology Innov. Infrastruct. Solut. 7 1 13

M Sarafrazi M Hamadanian AR Ghasemi 2019 Optimize epoxy matrix with RSM/CCD method and influence of multi-wall carbon nanotube on mechanical properties of epoxy/polyurethane Mech. Mater. 138 103154https://doi.org/10.1016/j.mechmat.2019.103154

SI Haruna H Zhu J Shao 2022 Experimental study, modeling, and reliability analysis of impact resistance of micro steel fiber-reinforced concrete modified with nano silica Struct. Concr. https://doi.org/10.1002/SUCO.202100651

A Khodaii ES Mousavi M Khedmati A Iranitalab 2016 Identification of dominant parameters for stripping potential in warm mix asphalt using response surface methodology Mater. Struct. 49 2425 2437 https://doi.org/10.1617/s11527-015-0658-7

S Gogoi S Barua N Karak 2015 Cross-linking kinetics of hyperbranched epoxy cured hyperbranched polyurethane and optimization of reaction conversion by central composite design Chem. Eng. Sci. 127 230 238 https://doi.org/10.1016/j.ces.2015.01.053

Z Zhang J Sun Z Huang F Wang M Jia W Lv J Ye 2021 A laboratory study of epoxy/polyurethane modified asphalt binders and mixtures suitable for flexible bridge deck pavement Constr. Build. Mater. 274 122084https://doi.org/10.1016/j.conbuildmat.2020.122084

J Shao H Zhu X Zuo W Lei S Mirgan J Liang F Duan 2020 Effect of waste rubber particles on the mechanical performance and deformation properties of epoxy concrete for repair Constr. Build. Mater. 241 118008https://doi.org/10.1016/j.conbuildmat.2020.118008

DL/T, 5151–2001: (2001) Test code for aggregates of hydraulic concrete

ASTM C192: Standard practice for making and curing concrete test specimens in the laboratory.

GB/T18850–2002: Industry wire screens-Technical requirements and testing

MM Demir I Yilgor E Yilgor B Erman 2002 Electrospinning of polyurethane fibers Polymer (Guildf). 43 3303 3309 https://doi.org/10.1016/S0032-3861(02)00136-2

ASTM C138 / C138M - 01a: Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete

DL/T5126–2001: Test code on polymer-modified cement martor, National Standard of China, 2001.

DL/T5193–2004:, China National StandardTechnical code of epoxy resin mortar.

D.C. Montgomery: Design and analysis of experiments, John wiley & sons (2017)

NGS Silva LICO Cortat D Orlando DR Mulinari 2020 Evaluation of rubber powder waste as reinforcement of the polyurethane derived from castor oil Waste Manag. 116 131 139 https://doi.org/10.1016/j.wasman.2020.07.032

Hesami, S.; Salehi Hikouei, I.; Emadi, S.A.A.: Mechanical behavior of self-compacting concrete pavements incorporating recycled tire rubber crumb and reinforced with polypropylene fiber. J. Clean. Prod. 133, 228–234 (2016). Doi: https://doi.org/10.1016/j.jclepro.2016.04.079

S.K. Subramaniyan, S. Mahzan, M.I. bin Ghazali, M. Bin Ismon, A.M.A. Zaidi, Mechanical Behavior of Polyurethane Composite Foams from Kenaf Fiber and Recycled Tire Rubber Particles, Appl. Mech. Mater. 315 (2013) 861–866. https://doi.org/10.4028/www.scientific.net/AMM.315.861.

Adamu, M.; Mohammed, B.S.; Shahir Liew, M.: Mechanical properties and performance of high volume fly ash roller compacted concrete containing crumb rubber and nano silica. Constr. Build. Mater. 171, 521–538 (2018). Doi: https://doi.org/10.1016/j.conbuildmat.2018.03.138

CM Landis T Pardoen JW Hutchinson 2000 Crack velocity dependent toughness in rate dependent materials Mech. Mater. 32 663 678 https://doi.org/10.1016/S0167-6636(00)00031-4

Hong, S.; Chew, H.B.; Kim, K.-S.: Cohesive-zone laws for void growth—I. Experimental field projection of crack-tip crazing in glassy polymers. J. Mech. Phys. Solids. 57, 1357–1373 (2009). https://doi.org/10.1016/j.jmps.2009.04.003

Acknowledgements

The authors greatly acknowledge the financial support of this research by the Natural Science Foundation of China (No. 51708314)

Author information

Authors and Affiliations

Contributions

HZ: Conceptualization, Investigation, Writing - review & editing, Supervision, Resources, Project administration, Funding acquisition Formal analysis. MSMA and SIH: Conceptualization, Methodology, Investigation, Data curation, Writing - original draft, Writing - review & editing, Visualization. JS: Data curation, Writing - original draft, Writing - review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al-kahtani, M.S.M., Zhu, H., Haruna, S.I. et al. Evaluation of Mechanical Properties of Polyurethane-Based Polymer Rubber Concrete Modified Ground Glass Fiber Using Response Surface Methodology. Arab J Sci Eng 48, 4695–4710 (2023). https://doi.org/10.1007/s13369-022-07112-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07112-w