Abstract

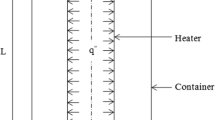

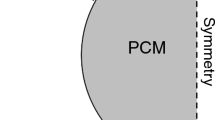

Computational studies were performed to investigate the melting process in a cubical closed space. Capric acid (CA)–stearic acid (SA) eutectic mixture is chosen as a phase change material (PCM). Some thermo-physical properties such as melting temperature, latent heat of fusion, specific heat capacity, thermal conductivity, thermal expansion coefficient, density and viscosity of CA-SA eutectic mixture prepared as PCM were measured. Considering these measured properties, the melting behavior of the prepared eutectic PCM was simulated numerically with finite volume method in a three-dimensional cavity. Non-isothermal heating conditions throughout phase change process of the PCM are considered in the numerical modeling study. It is shown that temperature difference has a significant impact on the melting, while its behavior changes for various cross sections. It is observed that the melting does not change after 80 min for the studied PCM. Significant variations for the melting behavior are observed between 2D and 3D configurations. Melt fraction is only 1.20% higher in 3D case as compared to 2D case at t = 130 min and Gr = 1.8 × 105, while this value is 1.08% at Gr = 3.6 × 104.

Similar content being viewed by others

Abbreviations

- f:

-

Liquid fraction

- g:

-

Gravitational acceleration (m/s2)

- Gr:

-

Grashof number

- h:

-

Local heat transfer coefficient (W/m2K)

- H:

-

Total enthalpy (J/kg)

- k:

-

Thermal conductivity (W/mK)

- L:

-

Latent heat (J/kg)

- Nu:

-

Nusselt number

- p:

-

Pressure (Pa)

- Pr:

-

Prandtl number

- Ra:

-

Rayleigh number

- Ste:

-

Stefan number

- T:

-

Temperature (K)

- t:

-

Time (s)

- u, v, w:

-

x–y-z Velocity components (m/s)

- U, V, W:

-

Dimensionless velocity components

- x, y, z:

-

Cartesian coordinates (m)

- X, Y, Z:

-

Dimensionless coordinates

- α :

-

Thermal diffusivity (m2/s)

- β :

-

Thermal expansion coefficient (1/K)

- τ :

-

Non-dimensional time

- c:

-

Cold

- h:

-

Hot

- m:

-

Melting

- ave:

-

Average

- ref:

-

Reference

References

Hasan, A.; McCormack, S.; Huang, M.; Norton, B.: Evaluation of phase change materials for thermal regulation enhancement of building integrated photovoltaics. Sol. Energy 84, 1601–1612 (2010)

Park, J.; Kim, T.; Leigh, S.B.: Application of a phase-change material to improve the electrical performance of vertical-building-added photovoltaics considering the annual weather conditions. Sol. Energy 105, 561–574 (2014)

Huang, M.; Eames, P.; Norton, B.: Thermal regulation of building-integrated photovoltaics using phase change materials. Int. J. Heat Mass Transf. 47, 2715–2733 (2003)

Lin, W.; Ma, Z.; Sohel, M.I.; Cooper, P.: Development and evaluation of a ceiling ventilation system enhanced by solar photovoltaic thermal collectors and phase change materials. Energy Convers. Manag. 88, 218–230 (2014)

Smith, C.J.; Forster, P.M.; Crook, R.: Global analysis of photovoltaic energy output enhanced by phase change material cooling. Appl. Energy 126, 21–28 (2014)

Ho, C.; Tanuwijava, A.; Lai, C.M.: Thermal and electrical performance of a BIPV integrated with a microencapsulated phase change material layer. Energy Build. 50, 331–338 (2012)

Brano, V.L.; Ciulla, G.; Piacentino, A.; Cardona, F.: Finite difference thermal model of a latent heat storage system coupled with a photovoltaic device: description and experimental validation. Renew. Energy 68, 181–193 (2014)

Pahamli, Y.; Hosseini, M.J.; Ranjbar, A.A.; Bahrampoury, R.: Analysis of the effect of eccentricity and operational parameters in PCM-filled single-pass shell and tube heat exchangers. Renew. Energy 97, 344–357 (2016)

Jin, X.; Medina, M.A.: Zhang XNumerical analysis for the optimal location of a thin PCM layer in frame walls. Appl. Thermal Eng. 103, 1057–1063 (2016)

Ismail, K.A.R.; de Jesus, A.B.: Modeling and solution of the solidification problem of PCM around a cold cylinder. Numer. Heat Transfer Part A Appl. 36, 95–114 (1999)

Srivatsa, P.V.S.S.; Baby, R.; Balaji, C.: Numerical investigation of PCM based heat sinks with embedded metal foam/crossed plate fins. Numer. Heat Transfer Part A Appl. 66, 1131–1153 (2014)

Yilbas, B.S.; Shuja, S.Z.; Shaukat, M.M.: Thermal characteristics of latent heat thermal storage: comparison of aluminum foam and mesh configurations. Numer. Heat Transfer Part A Appl. 68, 99–116 (2015)

Gharebaghi, M.; Sezai, I.: Enhancement of heat transfer in latent heat storage modules with internal fins. Numer. Heat Transfer Part A Appl. 53, 749–765 (2007)

Jmal, I.; Baccar, M.: Numerical study of PCM solidification in a finned tube thermal storage including natural convection. Appl. Therm. Eng. 84, 320–330 (2015)

Mumtaz, M.; Khan, A.; Ibrahim, N.I.; Mahbubul, I.M.; Ali, H.M.; Al-Sulaiman, F.A.: Evaluation of solar collector designswith integrated latent heat thermal energy storage: a review. Sol. Energy 166, 334–350 (2018)

Piratheepan, M.; Anderson, T.: An experimental investigation of turbulent forced convection heat transfer by a multi-walled carbon-nanotube nanofluid. Int. Commun. Heat Mass Transfer 57, 286–290 (2014)

Kamali, R.; Binesh, A.: Numerical investigation of heat transfer enhancement using carbon nanotube based non-Newtonian nanofluids. Int. Commun. Heat Mass Transfer 37, 1153–1157 (2010)

Murshed, S.; de Castro, C.A.N.: Superior thermal features of carbon nanotubes-based nano uids - a review. Renew. Sustain. Energy Rev. 37, 155–167 (2014)

Sheikholeslami, M.: Numerical simulation for solidification in a LHTESS by means of nano-enhanced PCM. J. Taiwan Inst. Chem. Eng. 86, 25–41 (2018)

Sheikholeslami, M.; de Haq, R.; Shafee, A.; Li, Z.: Heat transfer behavior of nanoparticle enhanced PCM solidification through an enclosure with V shaped fins. Int. J. Heat Mass Transfer. 130, 1322–1342 (2019)

Ghalambaz, M.; Chamkha, A.J.; Wen, D.: Natural convective flow and heat transfer of nano-encapsulated phase change materials (NEPCMs) in a cavity. Int. J. Heat Mass Transf. 138, 738–749 (2019)

Boukani, N.H.; Dadvand, A.; Chamkha, A.J.: Melting of a nano-enhanced phase change material (NePCM) in partially-filled horizontal elliptical capsules with different aspect ratios. Int. J. Mech. Sci. 138, 164–177 (2018)

Sadeghi, H.M.; Babayan, M.; Chamkha, A.J.: Investigation of using multi-layer PCMs in the tubular heat exchanger with periodic heat transfer boundary condition. Int. J. Heat Mass Transfer. 147, 118970 (2020)

Selimefendigil, F., Öztop, H. F.: Natural convection and melting of NEPCM in a corrugated cavity under the effect of magnetic field J. Therm. Anal. Calorim. 1–16 (2019)

Bondarenko, D.S.; Sheremet, M.A.; Oztop, H.F.; Ali, M.E.: Impacts of moving wall and heat-generating element on heat transfer and entropy generation of Al2O3/H2O nanofluid. J. Therm. Anal. Calorim. 136, 673–686 (2019)

Rashidi, S.; Shamsabadi, H.; Esfahani, J.A.; Harmand, S.: A review on potentials of coupling PCM storage modules to heat pipes and heat pumps. J. Thermal Anal. Calorim. 140, 1655–1713 (2020)

Jeong, S.G.; Cha, J.; Kim, S.; Seo, J.; Lee, J.H.; Kim, S.: Preparation of thermal-enhanced epoxy resin adhesive with organic PCM for applying wood flooring. J Therm Anal Calorim. 117, 1027–1034 (2014)

Liu, L.; Zhang, X.; Xu, X.; Zhao, Y.; Zhang, S.: The research progress on phase change hysteresis affecting the thermal characteristics of PCMs: a review. J. Mol. Liq. 317, 113760 (2020)

Voile, V.; Prakash, C.: A fixed grid numerical modeling methodology for convection diffusion mushy region phase-change problem. Int. J. Heat Mass Transfer 30, 1709–1719 (1987)

Elsanusi, O.E.; Nsofor, E.C.: Melting of multiple PCMs with different arrangements inside a heat exchanger for energy storage. Appl. Thermal Eng. 185, 116046 (2021)

Sarı, A.; Karaipekli, A.; Kaygusuz, K.: Capric acid and stearic acid mixture impregnated with gypsum wallboard for low-temperature latent heat thermal energy storage. Int. J. Energy Res. 3, 154–160 (2008)

Brent, A.D.; Voller, V.R.; Reid, K.T.J.: Enthalpy-porosity technique for modeling convection-diffusion phase change: application to the melting of a pure metal. Numer. Heat Transfer Part A Appl. 13, 297–318 (1988)

Bouzennada, T.; Mechighel, F.; Filali, A.; Ghachem, K.; Kolsi, L.: Numerical investigation of heat transfer and melting process in a PCM capsule: effects of inner tube position and Stefan number. Case Stud. Thermal Eng. 27, 101306 (2021)

Mehryan, S.A.M.; Tahmasebi, A.; Izadi, M.; Ghalambaz, M.: Melting behavior of phase change materials in the presence of a non-uniform magnetic-field due to two variable magnetic sources. Int. J. Heat Mass Transfer. 149, 119184 (2020)

Bondareva, N.S.; Sheremet, M.A.: 3D natural convection melting in a cubical cavity with a heat source. Int. J. Therm. Sci. 115, 43–53 (2017)

Dhaidan, S.N.; Khodadadi, J.M.; Al-Hattab, T.A.; Mashat, S.M.: Experimental and numerical investigation of melting of phase change material/nanoparticle suspensions in a square container subjected to a constant heat flux. Int. J. Heat Mass Transf. 66, 672–683 (2013)

Versteeg, H., Malalasekera, W.: An Introduction to Computational Fluid Dynamics: The Finite Volume Method. Pearson Education, Harlow, UK (2007)

Moukalled, F., Mangani, K., Darwish, M.: The Finite Volume Method in Computational Fluid Dynamics. Springer. (2015)

De Césaro Oliveski, R.; Becker, F.; Rocha, L.A.O.; Biserni, C.; Eberhardt, G.E.S.: Design of fin structures for phase change material (PCM) melting process in rectangular cavities. J. Energy Storage. 35, 102337 (2021)

Bechiri, M.; Mansouri, K.: Study of heat and fluid flow during melting of PCM inside vertical cylindrical tube. Int. J. Therm. Sci. 135, 235–246 (2019)

Abdollahzadeh, M.; Esmaeilpour, M.: Enhancement of phase change material (PCM) based latent heat storage system with nano fluid and wavy surface. Int. J. Heat Mass Transf. 80, 376–385 (2015)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical Statement

There is no ethical problem in this manuscript.

Rights and permissions

About this article

Cite this article

Coşanay, H., Selimefendigil, F., Öztop, H.F. et al. Experimental Analysis of Melting Behavior of Capric Acid (CA)–Stearic Acid (SA) Eutectic Mixture and its 3D Numerical Solution of Natural Convection in a Cup. Arab J Sci Eng 47, 15575–15589 (2022). https://doi.org/10.1007/s13369-022-06719-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-06719-3