Abstract

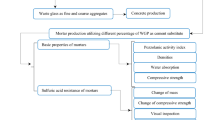

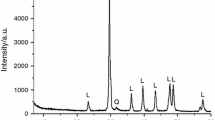

In this study, the usability of colemanite wastes (CW), in mortar mixtures, was examined in terms of compressive strength, while at the same time it was aimed to evaluate the effects of this waste on the rheological properties of mortar and paste mixtures. Mortar and cement paste mixtures were produced by substituting 1, 3, 5, and 7% of the cement with the CW. Marsh-funnel flow times, mini-slump values, rheological parameters, and setting times of cement paste mixtures containing CW were determined. The time-dependent slump-flow and 1-, 7-, 28-, and 56-day compressive strength values of the mortar mixtures were determined. The microstructures of the specimens were evaluated by using SEM images, and phase analyses were examined with XRD analysis. The results showed that the use of CW negatively affected the fresh state properties and rheological parameters of cementitious systems. However, CW addition decreased the 1-, 7-, and 28-day compressive strength. Only a slight increase was observed in the strength of mixtures containing 5 and 7% CW at 56 days.

Similar content being viewed by others

Data Availability

All data, models, and code generated or used during the study appear in the article.

References

Oss, H.G.; Padovani, A.C.: Cement manufacture and the environment part II: environmental challenges and opportunities. J. Ind. Ecol. 7, 93–126 (2003). https://doi.org/10.1162/108819803766729212

Chen, Z.X.; Chu, S.H.; Lee, Y.S.; Lee, H.S.: Coupling effect of γ-dicalcium silicate and slag on carbonation resistance of low carbon materials. J. Clean. Prod. 262, 121385 (2020). https://doi.org/10.1016/j.jclepro.2020.121385

Chen, J.J.; Ng, P.L.; Chu, S.H.; Guan, G.X.; Kwan, A.K.H.: Ternary blending with metakaolin and silica fume to improve packing density and performance of binder paste. Constr. Build. Mater. 252, 119031 (2020). https://doi.org/10.1016/j.conbuildmat.2020.119031

Chu, S.H.; Chen, J.J.; Li, L.G.; Ng, P.L.; Kwan, A.K.H.: Roles of packing density and slurry film thickness in synergistic effects of metakaolin and silica fume. Powder Technol. 387, 575–583 (2021). https://doi.org/10.1016/j.powtec.2021.04.029

Tokyay, M.: Cement and Concrete Mineral Admixtures. CRC Press, Cambridge (2016)

Li, G.; Zhao, X.: Properties of concrete incorporating fly ash and ground granulated blast-furnace slag. Cem. Concr. Compos. 25, 293–299 (2003). https://doi.org/10.1016/S0958-9465(02)00058-6

Shariq, M.; Prasad, J.; Masood, A.: Effect of GGBFS on time dependent compressive strength of concrete. Constr. Build. Mater. 24, 1469–1478 (2010). https://doi.org/10.1016/j.conbuildmat.2010.01.007

Farahani, A.; Taghaddos, H.; Shekarchi, M.: Prediction of long-term chloride diffusion in silica fume concrete in a marine environment. Cem. Concr. Compos. 59, 10–17 (2015). https://doi.org/10.1016/j.cemconcomp.2015.03.006

Giaccio, G.; de Sensale, G.R.; Zerbino, R.: Failure mechanism of normal and high-strength concrete with rice-husk ash. Cem. Concr. Compos. 29, 566–574 (2007). https://doi.org/10.1016/j.cemconcomp.2007.04.005

Singhal, V.; Nagar, R.; Agrawal, V.: Sustainable use of fly ash and waste marble slurry powder in concrete. Mater. Today Proc. (2020). https://doi.org/10.1016/j.matpr.2020.05.650

Chu, S.H.; Poon, C.S.; Lam, C.S.; Li, L.: Effect of natural and recycled aggregate packing on properties of concrete blocks. Constr. Build. Mater. 278, 122247 (2021). https://doi.org/10.1016/j.conbuildmat.2021.122247

Chu, S.H.; Li, L.; Shen, P.L.; Lu, J.X.; Poon, C.S.: Recycling of waste glass powder as paste replacement in green UHPFRC. Constr. Build. Mater. 316, 125719 (2022). https://doi.org/10.1016/j.conbuildmat.2021.125719

Siddique, R.: Utilization of industrial by-products in concrete. Procedia Eng. 95, 335–347 (2014). https://doi.org/10.1016/j.proeng.2014.12.192

Eti Mining Operations General Directorate: 2019 Sectoral Report of Boron (2020)

Akyıldız, A.: Investigation of usability of boric waste as a pozzolanic material in production of concrete (2012)

Bideci, Ö.S.; Bideci, A.: The effect of ground colemanite additive on cement mortars. Sci. Eng. J. Fırat Univ. 30, 133–138 (2018)

Sonmez, E.; Koca, S.; Ozdag, H.; Ipek, H.: Beneficiation of colemanite concentrates from fine wastes by using ultrasound waves. Miner. Eng. 17, 359–361 (2004). https://doi.org/10.1016/j.mineng.2003.11.008

Uysal, M.; Al-mashhadani, M.M.; Aygörmez, Y.; Canpolat, O.: Effect of using colemanite waste and silica fume as partial replacement on the performance of metakaolin-based geopolymer mortars. Constr. Build. Mater. 176, 271–282 (2018). https://doi.org/10.1016/j.conbuildmat.2018.05.034

Boncukcuoǧlu, R.; Yilmaz, M.T.; Kocakerim, M.M.; Tosunoǧlu, V.: Utilization of borogypsum as set retarder in Portland cement production. Cem. Concr. Res. 32, 471–475 (2002). https://doi.org/10.1016/S0008-8846(01)00711-6

Gemici, Ü.; Tarcan, G.; Helvacı, C.; Somay, A.M.: High arsenic and boron concentrations in groundwaters related to mining activity in the Bigadiç borate deposits (Western Turkey). Appl. Geochem. 23, 2462–2476 (2008). https://doi.org/10.1016/j.apgeochem.2008.02.013

Erdoğan, Y.; Zeybek, M.; Demirbaş, A.: Cement mixes containing colemanite from concentrator wastes. Cem. Concr. Res. 28, 605–609 (1998). https://doi.org/10.1016/S0008-8846(98)00018-0

Kula, I.; Olgun, A.; Erdogan, Y.; Sevinc, V.: Effects of colemanite waste, cool bottom ash, and fly ash on the properties of cement. Cem. Concr. Res. 31, 491–494 (2001). https://doi.org/10.1016/S0008-8846(00)00486-5

Kula, I.; Olgun, A.; Sevinc, V.; Erdogan, Y.: An investigation on the use of tincal ore waste, fly ash, and coal bottom ash as Portland cement replacement materials. Cem. Concr. Res. 32, 227–232 (2002). https://doi.org/10.1016/S0008-8846(01)00661-5

Targan, Ç.; Olgun, A.; Erdogan, Y.; Sevinc, V.: Effects of supplementary cementing materials on the properties of cement and concrete. Cem. Concr. Res. 32, 1551–1558 (2002). https://doi.org/10.1016/S0008-8846(02)00831-1

Targan, Ş; Olgun, A.; Erdogan, Y.; Sevinc, V.: Influence of natural pozzolan, colemanite ore waste, bottom ash, and fly ash on the properties of Portland cement. Cem. Concr. Res. 33, 1175–1182 (2003). https://doi.org/10.1016/S0008-8846(03)00025-5

Sevim, U.K.; Ozturk, M.; Bankir, M.B.; Aydin, U.: Utilization of colemanite waste in concrete design. Int. J. Adv. Eng. Res. Sci. 4, 172–175 (2017). https://doi.org/10.22161/ijaers.4.12.25

Sevim, U.K.: Colemanite ore waste concrete with low shrinkage and high split tensile strength. Mater. Struct. 44, 187–193 (2011). https://doi.org/10.1617/s11527-010-9618-4

Özdemir, M.; Öztürk, N.U.: Utilization of clay wastes containing boron as cement additives. Cem. Concr. Res. 33, 1659–1661 (2003). https://doi.org/10.1016/S0008-8846(03)00138-8

Mutuk, T.; Mesci, B.: Analysis of mechanical properties of cement containing boron waste and rice husk ash using full factorial design. J. Clean. Prod. 69, 128–132 (2014). https://doi.org/10.1016/j.jclepro.2014.01.051

Koumpouri, D.; Angelopoulos, G.N.: Effect of boron waste and boric acid addition on the production of low energy belite cement. Cem. Concr. Compos. 68, 1–8 (2016). https://doi.org/10.1016/j.cemconcomp.2015.12.009

Uçar, N.; Çalık, A.; Emre, M.; Akkurt, I.: Physical-radiation shielding properties of concrete contains colemanite and ulexite. Indoor Built Environ. (2020). https://doi.org/10.1177/1420326X20967974

Ozturk, M.; Sevim, U.K.; Akgol, O.; Unal, E.; Karaaslan, M.: Investigation of the mechanic, electromagnetic characteristics and shielding effectiveness of concrete with boron ores and boron containing wastes. Constr. Build. Mater. 252, 119058 (2020). https://doi.org/10.1016/j.conbuildmat.2020.119058

Gezmen, T.; Türkel, S.: Investigation of the mechanical characteristics and sulfate resistance of the mortars containing boron mineral and fly ash. Dokuz Eylul Univ. Fac. Eng. J. Sci. Eng. 19, 757–778 (2017). https://doi.org/10.21205/deufmd.2017195768

Durgun, M.Y.; Sevinç, A.H.: High temperature resistance of concretes with GGBFS, waste glass powder, and colemanite ore wastes after different cooling conditions. Constr. Build. Mater. 196, 66–81 (2019). https://doi.org/10.1016/j.conbuildmat.2018.11.087

Celik, A.; Yilmaz, K.; Canpolat, O.; Al-mashhadani, M.M.; Aygörmez, Y.; Uysal, M.: High-temperature behavior and mechanical characteristics of boron waste additive metakaolin based geopolymer composites reinforced with synthetic fibers. Constr. Build. Mater. 187, 1190–1203 (2018). https://doi.org/10.1016/j.conbuildmat.2018.08.062

Ali, N.; Canpolat, O.; Aygörmez, Y.; Al-Mashhadani, M.M.: Evaluation of the 12–24 mm basalt fibers and boron waste on reinforced metakaolin-based geopolymer. Constr. Build. Mater. 251, 118976 (2020). https://doi.org/10.1016/j.conbuildmat.2020.118976

Cicek, B.; Karadagli, E.; Duman, F.: Valorisation of boron mining wastes in the production of wall and floor tiles. Constr. Build. Mater. 179, 232–244 (2018). https://doi.org/10.1016/j.conbuildmat.2018.05.182

Cheng, H.; Wu, S.; Li, H.; Zhang, X.: Influence of time and temperature on rheology and flow performance of cemented paste backfill. Constr. Build. Mater. 231, 117117 (2020). https://doi.org/10.1016/j.conbuildmat.2019.117117

Colombo, A.; Geiker, M.R.; Justnes, H.; Lauten, R.A.; De Weerdt, K.: On the effect of calcium lignosulfonate on the rheology and setting time of cement paste. Cem. Concr. Res. 100, 435–444 (2017). https://doi.org/10.1016/j.cemconres.2017.06.009

Roussel, N.: Rheology of fresh concrete: from measurements to predictions of casting processes. Mater. Struct. Constr. 40, 1001–1012 (2007). https://doi.org/10.1617/s11527-007-9313-2

Banfill, P.F.G.; Rodríguez, O.; Sánchez de Rojas, M.I.; Frías, M.: Effect of activation conditions of a kaolinite based waste on rheology of blended cement pastes. Cem. Concr. Res. 39, 843–848 (2009). https://doi.org/10.1016/j.cemconres.2009.06.010

Ferraris, C.F.; Obla, K.H.; Hill, R.: The influence of mineral admixtures on the rheology of cement paste and concrete. Cem. Concr. Res. 31, 245–255 (2001). https://doi.org/10.1016/S0008-8846(00)00454-3

Robert, C.R.; Sathyan, D.; Anand, K.B.: Effect of superplasticizers on the rheological properties of fly ash incorporated cement paste. Mater. Today Proc. 5, 23955–23963 (2018). https://doi.org/10.1016/j.matpr.2018.10.188

Özkan, Ş.G., Çebi, H., Delice, S., Doğan, M.: Properties and mining of boron minerals. In: 2nd Industrial Raw Materials Symposium. İzmir, Turkey (1997)

Topçu, İB.; Boğa, A.R.: Effect of boron waste on the properties of mortar and concrete. Waste Manag. Res. J. Sustain. Circ. Econ. 28, 626–633 (2010). https://doi.org/10.1177/0734242X09345561

Sevim, U.K.; Tümen, Y.: Strength and fresh properties of borogypsum concrete. Constr. Build. Mater. 48, 342–347 (2013). https://doi.org/10.1016/j.conbuildmat.2013.06.054

Zhong, R.; Wille, K.: Material design and characterization of high performance pervious concrete. Constr. Build. Mater. 98, 51–60 (2015). https://doi.org/10.1016/j.conbuildmat.2015.08.027

Chu, S.H.: Effect of paste volume on fresh and hardened properties of concrete. Constr. Build. Mater. 218, 284–294 (2019). https://doi.org/10.1016/j.conbuildmat.2019.05.131

Aitcin, P.C.: High Performance Concrete. E & FN Spon, New York (1998)

Wedding, P.; Kantro, D.: Influence of water-reducing admixtures on properties of cement paste—a miniature slump test. Cem. Concr. Aggreg. 2, 95 (1980). https://doi.org/10.1520/CCA10190J

Mardani-Aghabaglou, A.; Boyaci, O.C.; Hosseinnezhad, H.; Felekoʇlu, B.; Ramyar, K.: Effect of gypsum type on properties of cementitious materials containing high range water reducing admixture. Cem. Concr. Compos. 68, 15–26 (2016). https://doi.org/10.1016/j.cemconcomp.2016.02.007

Mardani-Aghabaglou, A.; Felekoğlu, B.; Ramyar, K.: Effect of cement C3A content on properties of cementitious systems containing high-range water-reducing admixture. J. Mater. Civ. Eng. 29, 1–12 (2017). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001925

Mardani-Aghabaglou, A.; Son, A.E.; Felekoglu, B.; Ramyar, K.: Effect of cement fineness on properties of cementitious materials containing high range water reducing admixture. J. Green Build. 12, 142–167 (2017). https://doi.org/10.3992/1552-6100.12.1.142

Koyuncu, H., Bakıs, R., Taspolat, L.T., Yılmaz, G., Karacasu, M.: An ınvestigation on the use of borax mineral as Portland cement replacement material. In: 2nd International Boron Symposium. Eskişehir (2004)

Gencel, O.; Brostow, W.; Ozel, C.; Fizil, M.: An investigation on the concrete properties containing colemanite. Int. J. Phys. Sci. 5, 216–225 (2010)

Koehler, E., Fowler, D.: Development of a Portable rheometer for fresh Portland cement concrete (2004)

Davraz, M.: The effects of boron compounds on the properties of cementitious composites. Sci. Eng. Compos. Mater. 17, 1–17 (2010). https://doi.org/10.1515/secm.2010.17.1.1

Norvell, J.K.; Stewart, J.G.; Juenger, M.C.; Fowler, D.W.: Influence of clays and clay-sized particles on concrete performance. J. Mater. Civ. Eng. 19, 1053–1059 (2007). https://doi.org/10.1061/(ASCE)0899-1561(2007)19:12(1053)

Phethany, Y.: Effect of LOI of fly ash on properties of concrete (2017)

Boncukcuoğlu, R.; Kocakeri̇m, M.M.; Tosunoğlu, V.; Yilmaz, M.T.: Utilization of trommel sieve waste as an additive in Portland cement production. Cem. Concr. Res. 32, 35–39 (2002). https://doi.org/10.1016/S0008-8846(01)00625-1

Çallı, M.; Pehlivan, E.: Use of boron compounds as grinding aids with alcohol amines and their effect on portland cement setting points. Adv. Civ. Eng. 2018, 1–6 (2018). https://doi.org/10.1155/2018/3187984

Kunt, K.; Dur, F.; Ertınmaz, B.; Yıldırım, M.; Derun, E.; Pişkin, S.: Utilization of boron waste as an additive for cement production. Celal Bayar Univ. J. Sci. 11, 383–389 (2015)

Erdogmus, E.: Combined effect of waste colemanite and silica fume on properties of cement mortar. Sci. Eng. Compos. Mater. (2014). https://doi.org/10.1515/secm-2013-0041

Erdogmus, E.; Erdoǧan, Y.; Gencel, O.; Targan, S.; Avciata, U.: Influence of colemanite admixture on Portland cement durability. Adv. Cem. Res. 24, 155–164 (2012). https://doi.org/10.1680/adcr.10.00043

Kavas, T.; Olgun, A.; Erdogan, Y.; Once, G.: The effect of pectin on the physicochemical and mechanical properties of cement containing boron. Build. Environ. 42, 1803–1809 (2007). https://doi.org/10.1016/j.buildenv.2006.01.018

Bothe, J.V.; Brown, P.: Phase formation in the system CaO–Al2O3–B2O3–H2O at 23±1°C. J. Hazard. Mater. 63, 199–210 (1998). https://doi.org/10.1016/S0304-3894(98)00221-0

Cseteyi, L.J.; Glasser, F.P.: Borate retardation of cement set and phase relations in the system Na 2 O—CaO—B 2 O 3 —H 2 O. Adv. Cem. Res. 7, 13–19 (1995). https://doi.org/10.1680/adcr.1995.7.25.13

Chen, H.J.; Shih, N.H.; Wu, C.H.; Lin, S.K.: Effects of the loss on ignition of fly ash on the properties of high-volume fly ash concrete. Sustainability (2019). https://doi.org/10.3390/su11092704

Lei, L.; Plank, J.: A study on the impact of different clay minerals on the dispersing force of conventional and modified vinyl ether based polycarboxylate superplasticizers. Cem. Concr. Res. 60, 1–10 (2014). https://doi.org/10.1016/j.cemconres.2014.02.009

Nehdi, M.L.: Clay in cement-based materials: critical overview of state-of-the-art. Constr. Build. Mater. 51, 372–382 (2014). https://doi.org/10.1016/j.conbuildmat.2013.10.059

Davraz, M.; Kılınçarslan, Ş; Pehlivanoğlu, E.: The effects of accelerating admixture on the mechanical properties of boric acid added mortars. Acta Phys. Pol. A. 125, 263–267 (2014). https://doi.org/10.12693/APhysPolA.125.263

Aksoğan, O.; Binici, H.; Ortlek, E.: Durability of concrete made by partial replacement of fine aggregate by colemanite and barite and cement by ashes of corn stalk, wheat straw and sunflower stalk ashes. Constr. Build. Mater. 106, 253–263 (2016). https://doi.org/10.1016/j.conbuildmat.2015.12.102

Olgun, A.; Kavas, T.; Erdogan, Y.; Once, G.: Physico-chemical characteristics of chemically activated cement containing boron. Build. Environ. 42, 2384–2395 (2007). https://doi.org/10.1016/j.buildenv.2006.06.003

Solem-Tishmack, J.K.; McCarthy, G.J.; Docktor, B.; Eylands, K.E.; Thompson, J.S.; Hassett, D.J.: High-calcium coal combustion by-products: engineering properties, ettringite formation, and potential application in solidification and stabilization of selenium and boron. Cem. Concr. Res. 25, 658–670 (1995). https://doi.org/10.1016/0008-8846(95)00054-G

Sebök, T.; Šimonı́k, J.; Kulı́sek, K.: The compressive strength of samples containing fly ash with high content of calcium sulfate and calcium oxide. Cem. Concr. Res. 31, 1101–1107 (2001). https://doi.org/10.1016/S0008-8846(01)00506-3

Sevinç, A.H.; Durgun, M.Y.: Properties of high-calcium fly ash-based geopolymer concretes improved with high-silica sources. Constr. Build. Mater. 261, 120014 (2020). https://doi.org/10.1016/j.conbuildmat.2020.120014

Apagyi, Z.; Csetenyi, L.J.: Phase equilibrium study in the CaO-K2O-B2O3-H2O system at 25°C. Cem. Concr. Res. 31, 1087–1091 (2001). https://doi.org/10.1016/S0008-8846(01)00529-4

Acknowledgements

The authors would like to thank for their kind assistance to Eti Mine Works in providing the colemanite waste, Polisan Construction Chemicals Company in providing the water-reducing admixture, Polyfibers Company in providing the polypropylene fiber, and Bursa Cement Factory determining the chemical composition and physical properties of cement. In addition, the third and fourth authors acknowledge the scholarship provided by the Turkish council of higher education (YÖK 100/2000 Program) during their Ph.D. study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Özen, S., Durgun, M.Y., Kobya, V. et al. Effect of Colemanite Ore Wastes Utilization on Fresh Properties and Compressive Strength of Cementitious Systems. Arab J Sci Eng 47, 12873–12887 (2022). https://doi.org/10.1007/s13369-022-06641-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-06641-8