Abstract

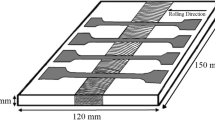

T-joints of dissimilar Al alloys are mainly prepared by mechanical connection in industry, which significantly increases the structural weight and is prone to stress concentration. In this paper, friction stir welding (FSW) technology was used to fabricate the T-joint consisting of 2024-T4 (skin) and 5083-O (stringer), and influences of process parameters on morphology and mechanical properties were investigated. In addition, the integrity and fracture characteristics of the welded joint were studied. The results showed that tunnel defects were easy to form at lower rotation speed or higher welding speed (V). Increasing the rotation speed (N) was instrumental in eliminating the tunnels, promoting the full mixing of the materials and forming "onion ring" structure; EBSD results show that the grain of the weld was obviously refined, and the dynamic recrystallization in the upper region is more sufficient than the lower region. The defects of fillet weld affected the mechanical properties of stringer whose fracture feature was ductile shear fracture, but the strength of the skin was not influenced by the defects and its fracture mode was dimple fracture. Ultimate tensile strength along the skin was up to 86% (403 MPa) of the base metal (BS) when N/W = 1200/60; Ultimate tensile load along the stringer was up to 118% (4575 N) of the BS when N/V = 1200/20. In summary, the reliable T-connection of dissimilar aluminum alloys required more heat input and the large fillet radius will improve the reliability of the connection although it narrowed the process window.

Similar content being viewed by others

References

Menzemer, C.; Lam, P.C.; Srivatsan, T.S.; Wittel, C.F.: An investigation of fusion zone microstructures of welded aluminum alloy joints. Mater. Lett. 41(4), 192–197 (1999)

Rai, R.; De, A.; Bhadeshia, H.K.D.H.; DebRoy, T.: Review: friction stir welding tools. Sci. Technol. Weld. Joi. 16(4), 325–342 (2011)

Feistauer, E.E.; Bergmann, L.A.; Dos Santos, J.F.: Effect of reverse material flow on the microstructure and performance of friction stir welded T-joints of an Al-Mg alloy. Mat. Sci. Eng. A-Struct. 731, 454–464 (2018)

Ren, D.; Zeng, F.; Liu, Y.; Liu, L.; He, Z.: Friction Stir Welding of 5754 Aluminum Alloy with Cover Sheet. Materials. 12, 1765 (2019)

Chaitanya, S., Vikas U., Narwariya, B.S.: Tensile properties of dissimilar friction stir weld joints of Al-2024 and Al-7039 alloys. Mater. Res. Express. 6, 026524 (2019)

Balamurugan, S.; Jayakumar, K.; Subbaiah, K.: Influence of friction stir welding parameters on dissimilar joints AA6061-T6 and AA5052-H32. Arab J Sci Eng (2021). https://doi.org/10.1007/s13369-021-05773-7

Li, C.; Zhang, D.; Gao, X.; Gao, H.X.; Han, X.: Numerical simulation and experimental research on friction stir welding of 2024–T3 aeronautical aluminum alloy. J Adhes Sci Technol. (2021). https://doi.org/10.1007/s13369-021-05773-7

Bandi, A.; Bakshi, S.R.: Effect of pin length and rotation speed on the microstructure and mechanical properties of friction stir welded lap joints of AZ31B-H24 Mg alloy and AA6061-T6 Al alloy. Metall Mater Trans A. 51(12), 6269 (2020)

Yin, K.; Cao, L.; Wang, N.: Mechanical properties and residual stresses of 5083 to AM60B dissimilar friction stir welding with different process parameters. J Adhes Sci Technol. 33(23), 2615–2629 (2019)

Cui, L.; Yang, X.Q.; Zhou, G.; Xu, X.D.; Shen, Z.K.: Characteristics of defects and tensile behaviors on friction stir welded AA6061-T4 T-joints. Mat. Sci. Eng. A-Struct. 543, 58–68 (2012)

Fratini, L.; Buffa, G.; Shivpuri, R.: Influence of material characteristics on plastomechanics of the FSW process for T-joints. Mater Design. 30(7), 2435–2445 (2009)

Manuel, N., Silva1, C., da Costa, J.M.D., Loureiro, A.: Friction stir welding of T-joints in dissimilar materials: Influence of tool geometry and materials properties. Mater. Res. Express. 6(10), 106528. (2019)

Lang, G.C.; Chang, K.H.; Lee, C.H.: Characteristics of the residual stress distribution in welded tubular T-joints. J Mech Sci Technol. 21(10), 1714–1719 (2007)

Krasnowski, K.: Technology of friction stir welding of aluminium alloy 6082 T-joints and their behaviour under static and dynamic loads. Materialwiss Werkst. 46(3), 256–268 (2015)

Acerra, F.; Buffa, G.; Fratini, L.; Troiano, G.: On the FSW of AA2024-T4 and AA7075-T6 T-joints: an industrial case study. Int J Adv Manuf Tech. 48(9–12), 1149–1157 (2010)

Zhao, Y.; Zhou, L.L.; Wang, Q.Z.; Yan, K.; Zou, J.S.: Defects and tensile properties of 6013 aluminum alloy T-joints by friction stir welding. Mater Design. 57, 146–155 (2014)

Astarita, A.; Squillace, A.; Scala, A.; Prisco, A.: On the critical technological issues of friction stir welding T-joints of dissimilar aluminum alloys. J Mater Eng Perform. 21(8), 1763–1771 (2012)

Sun, T.; Wu, S.Y.; Shen, Y.F.; Jin, J.Y.; Lu, J.Z.; Qin, T.X.: Effect of traverse speed on the defect characteristic, microstructure, and mechanical property of friction stir welded T-joints of dissimilar Mg/Al Alloy. Adv Mater Sci Eng. 2020, 1–15 (2020)

Sumit, J.; Neeraj, S.; Rajat, G.: Dissimilar alloys (AA6082/AA5083) joining by FSW and parametric optimization using Taguchi, grey relational and weight method. J Eng Mech. 6, 51–66 (2018)

Jitender, K.; Hari, S.: Friction stir welding of AA5083 aluminium alloy: multi-response optimization using Taguchi-based grey relational analysis. Adv Mech Eng. 8(11), 1–10 (2016)

Kamal, K.J.; Neeraj, S.; Rajesh, K.; Deepak, M.: An experimental investigation and optimization of friction stir welding process for AA6082 T6 (cryogenic treated and untreated) using an integrated approach of Taguchi, grey relational analysis and entropy method. P I Mech Eng L-J Mat. 230(2), 454–469 (2016)

Mohammadi, J., Behnamian, Y., Mostafaei, Izadi, H., Saeid, T., Kokabi, A.H., Gerlich, A.P.: Friction stir welding joint of dissimilar materials between AZ31B magnesium and 6061 aluminum alloys: Microstructure studies and mechanical characterizations. Mater Charact. 101, 189–207. (2015)

Guo, Y., Ma, Y., Zhang, X.S., Qian, X.D., Li, J.: Study on residual stress distribution of 2024-T3 and 7075-T6 aluminum dissimilar friction stir welded joints. Eng Fail Anal. 118, 104911 (2020)

Ramesh, N.R., Kumar, V.S.S.: Experimental erosion-corrosion analysis of friction stir welding of AA 5083 and AA 6061 for sub-sea applications. Appl Ocean Res, 98, 102121 (2020)

Fratini, L.; Buffa, G.; Monaco, L.L.: Improved FE model for simulation of friction stir welding of different materials. Sci Technol Weld Joi. 15(3), 199–207 (2010)

Jesus, J.S.; Costa, J.M.; Loureiro, A.; Ferreira, J.M.: Assessment of friction stir welding aluminium T-joints. J Mater Process Tech. 255, 387–399 (2018)

Colligan, K.: Material flow behavior during friction stir welding of aluminum. Weld J. 78(7), 229S-237S (1999)

Su, Y., Li, W.Y., Liu, X.C., Gao, F.Y., Yu, Y., Vairis, A. Evolution of microstructure, texture and mechanical properties of special friction stir welded T-joints for an alpha titanium alloy. Mater Charact. 177, 111152 (2021)

Liu, W.M.; Shen, Y.F.; Guo, C.; Ni, R.Y.; Yan, Y.F.; Hou, W.T.: Effect of rotational speed on microstructure and mechanical properties in submerged friction stir welding of ME20M magnesium alloy. J Mater Eng Perform. 28(8), 4610–4619 (2019)

Muthukumaran, S.; Mukherjee, S.K.: Multi-layered metal flow and formation of onion rings in friction stir welds. Int J Adv Manuf Tech. 38(1–2), 68–73 (2008)

Cui, G.R.; Ma, Z.Y.; Li, S.X.: Periodical plastic flow pattern in friction stir processed Al–Mg alloy. Scripta Mater. 58(12), 1082–1085 (2008)

Ujihara, T.F.K.S.; Fujiwara, K.; Sazaki, G.; Usami, N.; Nakajima, K.: Evaluation of the diffusion coefficients in liquid GaGe binary alloys using a novel method based on Fick’ s first law. J Non-Cryst Solids. 312(14), 196–202 (2002)

Hou W.T., Shen Z.K., Nazmul H.: Enhancing metallurgical and mechanical properties of friction stir butt welded joints of Al-Cu via cold sprayed Ni interlayer. Mat. Sci. Eng. A-Struct. 809, 140992 (2021)

Hou, W.T.; Shen, Y.F.; Huang, G.Q.: Dissimilar friction stir welding of aluminum alloys adopting a novel dual-pin tool: Microstructure evolution and mechanical properties. J Manuf Process. 36, 613–620 (2018)

Shi X.F., Li W, Hu W.W.: Effect of ECAP on the Microstructure and mechanical properties of a rolled Mg-2Y-0.6Nd-0.6Zr magnesium alloy. Crystals. 9(11), 1–12 (2019)

Zhang, Y.B.; Du, C.Y.; Li, J.N.: Mechanical properties of friction stir welded 2024 aluminum alloy and precipitated phases in stir zone. Kovove Mater. 55, 191–194 (2017)

Steuwer, A.; Peel, M.J.; Withers, P.J.: Dissimilar friction stir welds in AA5083–AA6082: the effect of process parameters on residual stress. Mat Sci Eng A-Struct. 441(1–2), 187–196 (2006)

Raweni, A.; Majstorovic, V.; Sedmak, A.; Tadic, S.; Kirin, S.: Optimization of AA5083 friction stir welding parameters using taguchi method. Teh Vjesn. 25(3), 861–866 (2018)

Yan, Y.F.; Shen, Y.F.; Lan, B.; Gao, J.C.: Influences of friction stir welding parameters on morphology and tensile strength of high density polyethylene lap joints produced by double-pin tool. J Manuf Process. 28, 33–40 (2017)

Krasnowski, K.: Experimental study of FSW T-joints of EN-AW 6082–T6 and their behaviour under static loads. Arab J Sci Eng. 39(12), 9083–9092 (2014)

Ramesh, R.; Suresh, K.S.; Srinivasan, R.V.: Effect of process parameters on mechanical characterization of dissimilar friction stir welded aluminium alloys. Appl Mech Mater. 766–767, 701–704 (2015)

Al-Roubaiy, A.O.; Nabat, S.M.; Batako, A.D.: An investigation into friction stir welding of aluminium alloy 5083–H116 similar joints. Mater. Today. 22, 2140–2152 (2020)

Zhang, H.J.; Liu, X.; Liu, H.J.; Mei, R.B.; Chen, X.G.: Interfacial feature and mechanical property of friction stir lap repair welded 7B04 aluminum alloy. J Mater Eng Perform. 29(10), 6890–6897 (2020)

Zhu, H.; Qi, F.: Mechanical properties and fracture behaviors on 6061 aluminum alloy under shear stress state. Rare Met. 30(5), 550–554 (2011)

Shen, Z.; Ding, Y.; Guo, W.: Refill friction stir spot welding al alloy to copper via pure metallurgical joining mechanism. Chin. J. Mech. Eng. 34(1), 1–8 (2021)

Funding

We are grateful for the financial support from the Funding of JiangSu Innovation Program for college student (Grant No. 202110287046Z).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Sun, T., Shen, Y., Ni, R. et al. Influences of Process Parameters on Morphology and Mechanical Properties of FSW-T-Joint of 2024/5083 Al Alloy Sheets. Arab J Sci Eng 47, 15195–15208 (2022). https://doi.org/10.1007/s13369-021-06494-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06494-7