Abstract

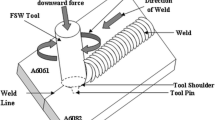

Friction stir welding is one of the solid-state welding to join the dissimilar alloys with elevated mechanical strength. In this experimental approach, the impact of process parameters on the mechanical characteristics of different metals or alloys formed by friction stir welding between AA5383 and AA7075 is determined, to optimize these parameters and to determine which ones are important using the Taguchi optimization procedure. The friction stir welding joints are generated experimentally at various factors of joining parameters, and that are rotational speed, feed and tilt angle of tool. The Taguchi approach has confirmed that the rotational speed is the most significant parameter than feed and tilt angle. The ANOVA shows that the selected parameters show individual and combined influence over mechanical properties. The prediction equation is proposed for predicting mechanical characteristics by using general linear model, and contour graph examination is employed for checking the effect of input parameters. The optimized joining parameters are determined for maximizing tensile and impact strength and minimizing the hardness of the welded specimens. The general linear analysis-based ANOVA approach has confirmed that the selected process parameters show combined and individual influence on impact strength. The optimized process parameters for maximizing tensile strength and hardness of the welded specimens are 1200 rpm of rotational speed, feed of 20 mm/min and tilt angle of 1.5°. The 1200 rpm of rotational speed, 60 mm/min of feed and 1.5° of tilt angle are the optimized process parameters for maximizing impact strength.

Similar content being viewed by others

Availability of Data and Materials

The data sets used and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Suresh Babu, B.; Gb, C.; Boopathi, C.; Pridhar, T.; Srinivasan, R.: Production and characterization of mechanical and microstructural behaviour of friction stir welded Al6063 composites reinforced with Gr/B4C/SiC particles. J. Ceram. Process. Res. 19(1), 69–74 (2018)

Thirumalai, R.; Prakash, R.; Ragunath, R.; Senthilkumar, K.M.: Experimental investigation of mechanical properties of epoxy based composites. Mater. Res. Exp. 6, 1–8 (2019)

Shunmugasundaram, M.; Maneiah, D.; Lingampalle, M.; Nagaraj, C.; Patil, P.: An optimization of joining parameters for stir cast aluminium metal matrix composites to improve material removal rate. Int. J. Mech. Prod. Eng. Res. Develop. 9, 951–960 (2019)

Thirumalai, R.; Seenivasan, M.; Panneerselvam, K.: Experimental investigation and multi response optimization of turning joining parameters for Inconel 718 using TOPSIS approach. Mater. Today Proc. (2020). https://doi.org/10.1016/j.matpr.2020.02.00

Essa, A.R.S.; Ahmed, M.M.Z.; Mohamed, A.-K.Y.A.: An analytical model of heat generation for eccentric cylindrical pin in friction stir welding. J. Market. Res. 5, 234–240 (2016)

Shunmugasundaram, M.; Praveen Kumar, A.; Maneiah, D.: An experimental analysis and joining parameter optimization on friction stir welded dissimilar alloys. Int. J. Mech. Prod. Eng. Res. Dev. 9, 407–414 (2019)

Vijayan, S.; Raju, R.; Rao, S.K.: Multiobjective optimization of friction stir welding process parameters on aluminum alloy AA 5083 using Taguchi-based grey relation analysis. Mater. Manuf. Processes 3, 1206–1212 (2010)

Güven, I.; Erim, S.; Çam, G.: Effects of temper condition and post weld heat treatment on the microstructure and mechanical properties of friction stir butt-welded AA7075 Al alloy plates. Int. J. Adv. Manuf. Technol. 70, 201–213 (2014)

Song, Y.; Yang, X.; Cui, L.; Hou, X.; Shen, Z.; Xu, Y.: Defect features and mechanical properties of friction stir lap welded dissimilar AA2024-AA7075 aluminum alloy sheets. Mater. Des. 55, 9–18 (2014)

Shunmugasundaram, M.; Praveen Kumar, A.; Amudhavalli, N.K.; Sivasankar, S.: Parametric optimization on tensile strength of friction stir butt joints of dissimilar AA6061 and AA5052 aluminium alloys by Taguchi technique. Mater Today Proc (2020). https://doi.org/10.1016/j.matpr.2020.02.166

Bijanrostami, K.; Barenji, R.V.; Hashemipour, M.: Effect of traverse and rotational speeds on the tensile behavior of the underwater dissimilar friction stir-welded aluminum alloys. J. Mater. Eng. Perform. 26, 909–920 (2017)

Ghosh, M.; Husain, M.M.; Kumar, K.; Kailas, S.V.: Friction stir-welded dissimilar aluminum alloys: microstructure, mechanical properties, and physical state. J. Mater. Eng. Perform. 22, 3890–3901 (2013)

Koilraj, M.; Sundareswaran, V.; Vijayan, S.; Koteswara Rao, S.R.: Friction stir welding of dissimilar aluminum alloys AA2219 to AA5083: optimization of process parameters using Taguchi technique. Mater. Des. 42, 1–7 (2012)

Elatharasan, G.; Senthil Kumar, V.S.: Modelling and Optimization of friction stir welding parameters for dissimilar aluminium alloys using RSM. Proc. Eng. 38, 3477–3481 (2012)

Yuvaraj, K.P.; Ashoka Varthanan, P.; Haribabu, L.; Madhubalan, R.; Boopathiraja, K.P.: Optimization of FSW tool parameters for joining dissimilar AA7075-T651 and AA6061 aluminium alloys using Taguchi Technique. Mater. Today Proc. (2020). https://doi.org/10.1016/j.matpr.2020.02.942

Kumar, S.; Kumar, S.: Multi-response optimization of process parameters for friction stir welding of joining dissimilar Al alloys by gray relation analysis and Taguchi method. J Braz. Soc. Mech. Sci. Eng. 37, 665–674 (2015). https://doi.org/10.1007/s40430-014-0195-2

Gupta, S.K.; Pandey, K.; Kumar, R.: Multi-objective optimization of friction stir welding process parameters for joining of dissimilar AA5083/AA6063 aluminum alloys using hybrid approach. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 232, 343–353 (2018)

Chanakyan, C.; Sivasankar, S.; Alagarsamy, S.V.; Dinesh Kumar, S.; Sakthivelu, S.; Meignanamoorthy, M.; Ravichandran, M.: Parametric optimization for friction stir welding with AA2024 and AA6061 aluminium alloys by ANOVA and GRG. Mater. Today Proc. 27, 707–711 (2020). https://doi.org/10.1016/j.matpr.2019.11.257

Hasan, M.M.; Ishak, M.; Rejab, M.R.M.: Effect of pin tool flute radius on the material flow and tensile properties of dissimilar friction stir welded aluminum alloys. Int. J. Adv. Manuf. Technol. 98, 2747–2758 (2018)

Palanivel, R.; Laubscher, R.; Vigneshwaran, S.; Dinaharan, I.: Prediction and optimization of the mechanical properties of dissimilar friction stir welding of aluminum alloys using design of experiments. Proc. Inst Mech. Eng. Part B J. Eng. Manuf. 232, 1384–1394 (2016)

Ilangovan, M.; Boopathy, S.R.; Balasubramanian, V.: Effect of tool pin profile on microstructure and tensile properties of friction stir welded dissimilar AA 6061–AA 5086 aluminium alloy joints. Defence Technol. 11, 174–184 (2015)

Kasman, S.; Kahraman, F.; Emiralioglu, A.: A case study for the welding of dissimilar EN AW 6082 and EN AW5083 aluminum alloys by friction stir welding. Metals (2016). https://doi.org/10.3390/met7010006

Saravanan, V.; Rajakumar, S.; Banerjee, N.; Amuthakkannan, R.: Effect of shoulder diameter to pin diameter ratio on microstructure and mechanical properties of dissimilar friction stir welded AA2024-T6 and AA7075-T6 aluminum alloy joints. Int. J. Adv. Manuf. Technol. 87, 3637–3645 (2016)

Acknowledgements

The authors are highly grateful to CMR Technical Campus, Hyderabad, and Bansal Institute of Science and Technology, Anand Nagar Bhopal, for providing basic facilities to compile this work.

Author information

Authors and Affiliations

Contributions

MS wrote the original draft. SN and PKC contributed to resources and supervision. MYR edited the manuscript. AK helped in reviewing and final drafting. UR helped in writing draft.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Shunmugasundaram, M., Nagarajan, S.M., Reddy, Y. et al. An Experimental Study and Joining Parameters Optimization of Friction Stir Weld Butt Joint by Taguchi Approach to Maximize the Mechanical Properties. Arab J Sci Eng 47, 8601–8615 (2022). https://doi.org/10.1007/s13369-021-06352-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06352-6