Abstract

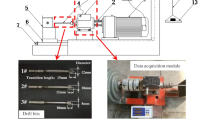

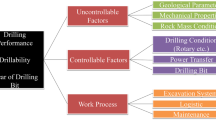

Reasonable selection of process parameters in drilling and coring is of great significance for reducing coring time and working costs. To reduce exploration costs and improve rock breaking efficiency, vertical shaft drilling rigs are used to study the influence of drilling rig working parameters, environmental parameters, and bit types on rock breaking efficiency. The rate of penetration (ROP) is used as the evaluation index of rock breaking efficiency. The sensitivity of drilling efficiency to drilling process parameters is analyzed through orthogonal experiments. The results show that the best combination of parameters in the test range is rotation speed 369 rpm, water flow rate 5L/min, and drill bit type is polycrystalline diamond composite (PDC) bit. The bit type has a significant impact on the drilling efficiency, the sensitivity to this parameter was high, and the weight value of the bit type is 61.36%. In contrast, the influence of rotation speed and water flow rate on the ROP is general, the sensitivity of these two parameters is low, and the weight values are 28.03 and 10.61%, respectively. The research results of this paper provide certain theoretical guidance for the reasonable selection of process parameters of drilling and coring.

Similar content being viewed by others

References

Cai, M.F.; Xue, D.L.; Ren, F.H.: Current status and development strategy of metal mines. Chin. J. Eng. 41, 417–426 (2019)

Kang, H.P.; Wang, G.F.; Jiang, P.F.: Conception for strata control and intelligent mining technology in deep coal mines with depth more than 1000m. J. China Coal Soc. 43, 1789–1800 (2018)

Perrone, D.; Jasechko, S.: Deeper well drilling an unsustainable stopgap to groundwater depletion. Nat. Sustain. 2, 773–782 (2019)

Huang, K.L.; Yang, Y.X.; Liu, Y.: Study on rock breaking mechanism of PDC bit with rotating module. J. Petroleum Sci. Eng. 192, 107312 (2020)

Ju, P.Z.; Wang, Q.; Zhai, Y.H.: Numerical simulation study on the optimization design of the crown shape of PDC drill bit. J. Petroleum Explor. Prod. Technol. 4, 343–350 (2014)

Ma, Y.C.; Huang, Z.Q.; Li, Q.: Cutter layout optimization for reduction of lateral force on PDC bit using kriging and particle swarm optimization methods. J. Petrol. Sci. Eng. 163, 359–370 (2018)

Yang, Y.X.; Yang, Y.; Liu, X.M.: Optimized design and application of a directional reaming-while-drilling polycrystalline diamond compact bit. Eng. Fail. Anal. 105, 699–707 (2019)

Lu, Y.Y.; Xiao, S.Q.; Ge, Z.L.: Experimental study on rock-breaking performance of water jets generated by self-rotatory bit and rock failure mechanism. Powder Technol. 346, 203–216 (2019)

Liu, W.J.; Zhu, X.H.; Li, B.: The rock breaking mechanism analysis of rotary percussive cutting by single PDC cutter. Arab. J. Geosci. 11, 1–11 (2018)

Feng, S.X.; Wang, Y.J.; Zhang, G.L.: Estimation of optimal drilling efficiency and rock strength by using controllable drilling parameters in rotary non-percussive drilling. J. Petroleum Sci. Eng. 193, 107376 (2020)

Sheng, M.; Tian, S.C.; Zhang, B.: Frequency analysis of multi-sources acoustic emission from high-velocity waterjet rock drilling and its indicator to drilling efficiency. Int. J. Rock Mech. Min. Sci. 115, 137–144 (2019)

Song, H.Y.; Shi, H.Z.; Ji, Z.S.: The percussive process and energy transfer efficiency of percussive drilling with consideration of rock damage. Int. J. Rock Mech. Min. Sci. 119, 1–11 (2019)

Li, G.; Yang, M.; Meng, Y.F.: The assessment of correlation between rock drillability and mechanical properties in the laboratory and in the field under different pressure conditions. J. Nat. Gas Sci. Eng. 30, 405–413 (2016)

Millett, J.M.; Wilkins, A.D.; Campbell, E.: The geology of offshore drilling through basalt sequences: understanding operational complications to improve efficiency. Mar. Pet. Geol. 77, 1177–1192 (2016)

Simon, R.: Energy balance in rock drilling. Soc. Petrol. Eng. J. 3, 298–306 (1963)

Teale, R.: The concept of specific energy in rock drilling. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 2, 57–73 (1965)

Bourgoyne, A.T.; Young, F.S.: A multiple regression approach to optimal drilling and abnormal pressure detection. Soc. Petrol. Eng. J. 14, 371–384 (1974)

Liu, W.J.; Zhu, X.H.: A new approach of rock cutting efficiency evaluation by using plastic energy dissipation ratio. Korean Soc. Civil Eng. 23, 879–888 (2019)

Soares, C.; Daigle, H.; Gray, K.: Evaluation of PDC bit ROP models and the effect of rock strength on model coefficients. J. Nat. Gas Sci. Eng. 34, 1225–1236 (2016)

Motahhari, H.R.; Hareland, G.; James, J.A.: Improved drilling efficiency technique using integrated PDM and PDC bit parameters. J. Can. Pet. Technol. 49, 45–52 (2010)

Zhang, G.Z.; Konietzky, H.; Frühwirt, T.: Investigation of scratching specific energy in the cerchar abrasivity test and its application for evaluating rock-tool interaction and efficiency of rock cutting. Wear. 448–449, 203218 (2020)

Wang, X.; Su, O.: Specific energy analysis of rock cutting based on fracture mechanics: a case study using a conical pick on sandstone. Eng. Fract. Mech. 213, 197–205 (2019)

Cheng, Z.; Sheng, M.; Li, G.S.: Imaging the formation process of cuttings: characteristics of cuttings and mechanical specific energy in single PDC cutter tests. J. Petrol. Sci. Eng. 171, 854–862 (2018)

Oloruntobi, O.; Butt, S.: Application of specific energy for lithology identification. J. Petroleum Sci. Eng. 184, 106402 (2020)

Tiryaki, B.; Dikmen, A.C.: Effects of rock properties on specific cutting energy in linear cutting of sandstones by picks. Rock Mech. Rock Eng. 39, 89–120 (2006)

Mohammad, A.; KaKaie, R.; Ghavidel, M.: Drilling rate prediction of an open pit mine using the rock mass drillability index. Int. J. Rock Mech. Min. Sci. 73, 130–138 (2015)

Gan, C.; Cao, W.H.; Wu, M.: Prediction of drilling rate of penetration (ROP) using hybrid support vector regression: a case study on the Shennongjia area Central China. J. Petroleum Sci. Eng. 181, 106200 (2019)

Li, H.S., Liu, S.Y., Chang, H.H.: Experimental research on the influence of working parameters on the drilling efficiency. Tunnelling and Underground Space Technology in Corporating Trenchless Technology Research. 95, 103174 (2020)

Balaji, M.; Rao, K.V.; Rao, N.M.: Optimization of drilling parameters for drilling of TI-6Al-4V based on surface roughness, flank wear and drill vibration. Measurement 114, 332–339 (2018)

Perez, S.; Karakus, M.; Pellet, F.: Development of a tool condition monitoring system for impregnated diamond bits in rock drilling applications. Rock Mech. Rock Eng. 50, 1289–1301 (2017)

Li, X.J.; Hao, J.Y.: Orthogonal test design for optimization of synthesis of super early strength anchoring material. Constr. Build. Mater. 181, 42–48 (2018)

Gnedenko, B.V.: Theory of Probability, 6th edn. Routledge, London (2018)

Acknowledgements

The authors would like to thank the financial support from the National Natural Science Foundation of China (No. 51805041), the support of the Fundamental Research Funds for the Central Universities, CHD (No. 300102259204, 300203211252), Major Science and Technology Project of Henan Province (Innovation Demonstration Project) (No. 191110211500), Scientific Innovation Practice Project of Postgraduates of Chang’an University (No. 300103714005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, K., Xu, X., Li, J. et al. A Study of the Drilling Efficiency of Concrete Core Drilling Based on Parametric Orthogonal Experiments. Arab J Sci Eng 47, 11523–11532 (2022). https://doi.org/10.1007/s13369-021-06263-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06263-6