Abstract

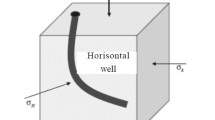

Hydraulic fracturing has been widely used in the petroleum industry for exploiting tight and ultra-tight formations. Although conventional hydraulic fracturing techniques have advanced significantly over time, it is still challenging to achieve separate intervals within multilayered formations, target the right layers and accurately fracture in succession. Hydra-jet-assisted fracturing, which involves boosting pressure in the cavity behind the casing to enable successful fracture initiation, is a technique often practiced to overcome this. However, there exists limited research regarding the pressure field within the cavity; therefore, this study aims to establish a mathematical model for predicting boosting pressure in the cavity under various reservoir conditions. In this paper, the authors present a numerical model to investigate the effects of nozzle differential pressure ratio of nozzle diameter to cavity diameter, annulus pressure and cavity length on boosting pressure. It is observed that the boosting pressure increases linearly with nozzle differential pressure and diameter ratio, respectively, while retaining other parameters as constant. However, simulations also indicate that annulus pressure and cavity length have minimal effect on the boosting pressure. In addition, the relationship between the boosting pressure coefficient and dimensionless standoff distance is also developed for specific diameter ratios, along with an insightful sensitivity analyses. A mathematical model is established to predict the final boosting pressure at different diameter ratios. As a result, this advances understanding of the design of treatment parameters in hydra-jet-assisted fracturing. Furthermore, this investigation is another step forward toward the global application of hydra-jet fracturing technology in developing deeper and layered tight gas sands.

Similar content being viewed by others

References

Meyer, B.R., Bazan, L.W., Jacot, R.H., Lattibeaudiere, M.G.: Optimization of multiple transverse hydraulic fractures in horizontal wellbores. In: SPE 131732. Unconventional gas conference. Pennsylvania. 23–25 Feb (2010)

Stanojcic, M., Jaripatke, O.A., Sharma, A.: Pinpoint fracturing technologies: a review of successful evolution of multistage fracturing in the last decade. In: SPE 130580. Coiled tubing and well intervention conference and exhibition. Texas. 23–24 Mar (2010)

Pongratz, R., Stanojcic, M., Martysevich, V.: PinPoint Multistage Fracturing Stimulation-Global Applications and Case Histories from Russia. In: SPE 114786. Russian oil and gas technical conference and exhibition, Moscow, 28–30 Oct (2008)

Rodgerson, J.L.; Lopez, E.; Snider, P.M.: Unique multistage process allows pinpoint treatment of hard-to-reach pay. SPE Prod. Oper. 21, 441–447 (2006)

Jakobsen, E., Dreisig, H.C.G., McDaniel, B.W.: Pinpoint hydrajet fracturing in multilayered sandstone formation completed with slotted liners. In: SPE 119444. Hydraulic fracturing technology conference, The Woodlands, 19–21 Jan (2009)

Wei, Y., Economides, M.J.: Transverse hydraulic fractures from a horizontal well. In: SPE 94671. Annual technical conference and exhibition. Dallas. 9–12 Oct (2005)

Surjaatmadja, J.B.: Finite Element analysis shows screenout development and cement bond destruction in horizontal wells. In: SPE 36867. International three-day conference and trade show on horizontal well technology, Milan, 22–24 Oct (1996)

Surjaatmadja, J.B., Grundmann, S., McDaniel, B., Deeg, W., Brumley J., Swor, L.: Hydrajet fracturing: an effective method for placing many fractures in openhole horizontal wells. In: SPE, 48856, Beijing, 2–6 Nov (1998)

Li, G., Huang, Z., Tian, S., Niu, J., Qu, H., Sheng, M.: Investigation and application of multistage hydrajet-fracturing in oil and gas well stimulation in China. In: SPE 131152. International oil and gas conference and exhibition, Beijing, 8–10 June (2010)

Qu, H.; Li, G.; Huang, Z.; Tian, S.: The boosting mechanism and effects in cavity during hydrajet fracturing process. Pet. Sci. Technol. 28, 1345–1350 (2010)

McDaniel, B.: Mature Assets to Unconventional Reservoirs: CT Deployed Hydrajet (Abrasive) Perforating Offers Many Stimulation Alternatives. In: IPTC 17982, International petroleum technology conference, Kuala Lumpur, Malaysia, 10–12 Dec (2014)

Surjaatmadja, J.B., Gijtenbeek, K.V.: Recent Advancements in Hydrajet Perforating and Stimulation Provide Better Penetration and Improve Stimulation. In: SPE144121, European formation damage conference, Noordwijk, The Netherlands, 7–10 June (2011)

Stockhausen, H.W., Garcia, D.G., Luongo, S.A., Surjaatmadja, J.B., Loghry, R.A.: In-depth evaluation of deep-rock Hydrajet results shows unique jetted rock surface characteristics. In: SPE 153333, EAGE annual conference and exhibition and SPE Europec, Copenhagen, Denmark, 4–7 June (2012)

Rhodes, D., Orski, K., N’Gouma, C., Guittiene, P.: Hydrajet fracture stimulation technique used to rejuvenate three wells in mature offshore oil field Congo-case history. In: SPE 144117, European formation damage conference, Noordwijk, The Netherlands, 7–10 June (2011)

Chellani, D., Gurnito, N., Ables, C.: Pinpoint-Fracturing technology improves efficiency while solving issues with conventional hydraulic-fracturing processes. In: SPE 151559, Middle East unconventional gas conference and exhibition, Abu Dhabi, 23–25 Jan (2012)

Mu, L., Ma, X., Zhang, Y., Ling, Y., Gu., Y., Zhou, D.: Evaluation of multi-stage fracturing by Hydrajet, Swellable packer, and compressive packer techniques in horizontal openhole wells. In: SPE 153328, EAGE annual conference and exhibition and SPE Europec, Copenhagen, Denmark, 4–7 June (2012)

Li, G., Sheng, M., Tian, S., Huang, Z., Li, Y., Yuan, X.: New technique: hydra-jet fracturing for effectiveness of multi-zone acid fracturing on an ultra deep horizontal well and case study. In: IADC/SPE 156398, Asia Pacific drilling technology conference and exhibition, Tianjin, China, 9–11 July (2012)

Hartley, J., Holden, D.: Evolution of a pinpoint stimulation technology and the benefits thereafter. In: SPE 163902, Coiled tubing and well intervention conference and exhibition, The Woodlands, Texas, USA, 26–27 Mar (2013)

Gomez, F., Al-Mutary, T., Abbas, H.H., Vielma, J.R., Al-Asiri, M.A., Sierra, L.: Successful oriented hydrajet perforation and fracture stimulation of a highly deviated tight-gas-producer well completed in the casing/liner overlap section. In: SPE 163893, Coiled tubing and well intervention conference and exhibition, The Woodlands, Texas, USA, 26–27 Mar (2013)

Pawar, B., Hriscu, J., Brand, S.: Benefits of remote activation and new downhole tool for pinpoint coiled tubing stimulation technology. In: SPE 173654, Coiled tubing and well intervention conference and exhibition, The Woodlands, Texas, USA, 24–25 Mar (2015)

Forni, P., Bonapace, J.C., Kovalenko, F., Garcia, M.N., Sorenson, F.: Conditioning pre-existing old vertical wells to stimulate and Test Vaca Muerta shale productivity through the application of pinpoint completion techniques. In: SPE 172724, Middle East oil and gas show and conference, Manama, Bahrain, 8–11 Mar (2015)

Chacon, A., Camilo, J., Fadul, J., Noguera, J.: Novel abrasive perforating with acid soluble material and subsequent Hydrajet assisted stimulation provides outstanding results in carbonate gas well. In: SPE 179083, Coiled tubing and well intervention conference and exhibition, Houston, Texas, USA, 22–23 Mar (2016)

Bonapace, J.C., Kovalenko, F., Sorenson, F., Forni P., Capsa, G., Barbalace, F.: Multipay well completion in Argentina: A versatile pinpoint completion technology applied through several conventional, tight, and shale reservoirs. In: SPE 185478, Latin American and Caribbean petroleum engineering conference, Buenos aires, Argentina, 17–19 May (2017)

AlBuali, M., AlDuaij, A.N., Hardegger, B., Bastisya, M.G., Khan, F.: Optimizing stimulation design using hydrajet fracturing process with Coiled tubing in Saudi Arabia gas well. In: SPE 183690, Middle East oil and gas show and conference, Manama, Bahrain, 6–9 Mar (2017)

Hu, Q., Zhu, F., Lv, W.: Simulating experiments of hydrajet perforating process. In: IADC/SPE 155879, Asia Pacific drilling technology conference and exhibition, Tianjin, China, 9–11 July (2012)

Hai, Q., Xiaoxiang, Z., Tingxue, J., Fei, Y.: Application of multistage hydrajet-fracturing technology in horizontal wells with slotted liner completion in China. In: IADC/SPE 170466, Asia pacific drilling technology conference, Bangkok, Thailand, 25–27 Aug (2014)

Surjaatmadja, J.B., Abbas, H.H.: Vertical minihole creation and fracturing technology for completing unconventional wells. In: SPE192073, Asia Pacific oil and gas conference and exhition, Brisbane, Australia, 23–25 Oct (2018)

Surjaatmadja, J.B.: Hydrajet-based fracturing treatment in unconventional wells. In: SPE195142, Middle East oil and gas show and conference, Manama, Bahrain, 18–21 Mar (2019)

Li, G.; Liu, Z.: Experimental study on the mechanism of hydrajet perforation. Nat. Sci. 26, 31–34 (2002)

Wen, C.: Modeling the boosting pressure in cavity and its application in predicting fracture geometry in hydrajet fracturing. MSc Thesis, The Petroleum Institute, Khalifa University, Abu Dhabi, UAE. Publisher: Ann Arbor, ProQuest Dissertations & Theses, (2015)

Chorin, A.J.: A numerical method for solving incompressible viscous flow problems. J. Comput. Phys. 2, 12–26 (1967)

Patankar, S.V.; Spalding, D.B.: A calculation procedure for heat, mass and momentum transfer in three-dimensional parabolic flows. Int. J. Heat Mass Transf. 15, 1787–1806 (1972)

Sheng, M.; Li, G.; Huang, Z.; Tian, S.; Qu, H.; Wu, C.: Numerical simulation of pressure boosting effect in jet hole during hydrajet fracturing. J Drill. Prod. Technol. China Univ. Pet. Beijing 34, 42–45 (2011)

Sheng, M.; Li, G.; Huang, Z.; Tian, S.; Qu, H.: Experimental study on hydraulic isolation mechanism during hydra-jet fracturing. Exp. Thermal Fluid Sci. 44, 722–726 (2013)

Acknowledgements

The authors would like to declare that this study was conducted as a research project funded by the Petroleum Institute, Khalifa University, and acknowledge the computing and software facilities (ANSYS FLUENT and ANSYS GAMBIT with student license) provided by Khalifa University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all the co-authors, the corresponding author, Md Motiur Rahman, states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Wen, C., Rahman, M.M., Shaik, A.R. et al. An Investigation into Boosting Pressure in the Cavity while Hydra-Jet-Assisted Fracturing: An Improved Model with Insightful Sensitivity Analysis. Arab J Sci Eng 47, 11421–11438 (2022). https://doi.org/10.1007/s13369-021-06184-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06184-4