Abstract

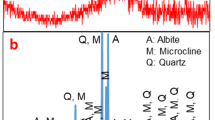

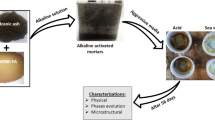

In general, building materials exposed to the marine environment are more prone to deteriorates than others. There are three main zones of the marine environment named atmospheric zone, tidal zone and submerged zone. This article investigated the effect of different curing conditions named water curing, air curing, seawater curing and wet/dry curing on the compressive strength and microstructure properties of alkali-activated slag (AAS) pastes with and without microsize metakaolin (mK) particles over a period of up to one year. The wet/dry curing was used to simulate the effect of the tidal zone, of which the specimens were submerged in seawater for 18 h followed by 6 h of air drying per day. The slag was partially replaced with mK at ratios fluctuated from 0 to 12% with a step of 2%, by weight. A fixed concentration of sodium silicate was used as an alkaline activator. After initial curing, the specimens were exposed to the aforementioned treatment conditions for 3, 6 and 12 M. The phase composition and microscopic structure of the neat AAS and AAS/mK samples were tested by X-ray diffraction (XRD), thermogravimetric analysis (TGA/DTG) and scanning electron microscopy (SEM). The results showed that the deterioration in the specimens exposed to the simulated tidal zone is more severe than those submerged in seawater. The neat AAS pastes showed better strength and microstructure than those blended with mK.

Similar content being viewed by others

References

Wang, D.; Noguchi, T.; Nozaki, T.: Increasing efficiency of carbon dioxide sequestration through high temperature carbonation of cement-based materials. J. Clean. Prod. 238, 117980 (2019)

I. IPCC: Special Report on Carbon Dioxide Capture and Storage. Cambridge University Press, Cambridge (2005)

Quéré, C.; Andrew, R.; Friedlingstein, P.; Sitch, S.; Hauck, J.; Pongratz, J.; Pickers, P.; Ivar Korsbakken, J.; Peters, G.; Canadell, J.: Global carbon budget 2018. Earth Syst. Sci. Data 10(4), 2141–2194 (2018)

Abriyantoro, D.; Dong, J.; Hicks, C.; Singh, S.P.: A stochastic optimisation model for biomass outsourcing in the cement manufacturing industry with production planning constraints. Energy 169, 515–526 (2019)

Rashad, A.M.: An overview on rheology, mechanical properties and durability of high-volume slag used as a cement replacement in paste, mortar and concrete. Constr. Build. Mater. 187, 89–117 (2018)

Rashad, A.M.: A brief on high-volume Class F fly ash as cement replacement—a guide for Civil Engineer. Int. J. Sustain. Built Environ. 4(2), 278–306 (2015)

Rashad, A.M.: A comprehensive overview about the influence of different additives on the properties of alkali-activated slag—a guide for Civil Engineer. Constr. Build. Mater. 47, 29–55 (2013)

Rashad, A.M.: Alkali-activated metakaolin: a short guide for Civil Engineer—an overview. Constr. Build. Mater. 41, 751–765 (2013)

Rashad, A.M.: A comprehensive overview about the influence of different admixtures and additives on the properties of alkali-activated fly ash. Mater. Des. 53, 1005–1025 (2014)

Islam, M.; Mondal, B.; Islam, M.: Effect of sea salts on structural concrete in a tidal environment. Aust. J. Struct. Eng. 10(3), 237–252 (2010)

Zhang, Y.; Jin, W.-L.: Distribution of chloride accumulation in marine tidal zone along altitude. ACI Mater. J. 108(5), 1 (2011)

Rashad, A.M.; Ouda, A.S.; Sadek, D.M.: Behavior of alkali-activated metakaolin pastes blended with quartz powder exposed to seawater attack. J. Mater. Civ. Eng. 30(8), 04018159 (2018)

Slaty, F.; Khoury, H.; Rahier, H.; Wastiels, J.: Durability of alkali activated cement produced from kaolinitic clay. Appl. Clay Sci. 104, 229–237 (2015)

Zhang, Z.; Yao, X.; Zhu, H.: Potential application of geopolymers as protection coatings for marine concrete: I. Basic properties. Appl. Clay Sci. 49(1–2), 1–6 (2010)

Li, X.; Rao, F.; Song, S.; Ma, Q.: Effect of cristobalite on the mechanical behaviour of metakaolin-based geopolymer in artificial seawater. Adv. Appl. Ceram. 119(1), 29–36 (2020)

Fernández-Jiménez, A.; García-Lodeiro, I.; Palomo, A.: Durability of alkali-activated fly ash cementitious materials. J. Mater. Sci. 42(9), 3055–3065 (2007)

Puertas, F.; Gutierrez, R.; Fernández-Jiménez, A.; Delvasto, S.; Maldonado, J.: Alkaline cement mortars. Chemical resistance to sulfate and seawater attack. Mater. Constr. 52(267), 55–71 (2002)

Zuhua, Z.; Xiao, Y.; Huajun, Z.: Potential application of geopolymers as protection coatings for marine concrete: II. Microstructure and anticorrosion mechanism. Appl. Clay Sci. 49, 7–12 (2010)

Reddy, D.V.; Edouard, J.-B.; Sobhan, K.: Durability of fly ash–based geopolymer structural concrete in the marine environment. J. Mater. Civ. Eng. 25(6), 781–787 (2013)

Rashad, A.M.; Shokry, K.M.: An exploratory study on alkali-activated slag paste blended with micro metakaolin subjected to thermal loads. Int. J. Mater. Eng. Technol. 13(2), 187 (2015)

Rashad, A.M.: Performance of autoclaved alkali-activated metakaolin pastes blended with micro-size particles derivative from dehydroxylation of kaolinite. Constr. Build. Mater. 248, 118671 (2020)

Rashad, A.M.; Sadek, D.M.: An investigation on Portland cement replaced by high-volume GGBS pastes modified with micro-sized metakaolin subjected to elevated temperatures. Int. J. Sustain. Built Environ. 6(1), 91–101 (2017)

Rashad, A.M.: Investigation on high-volume fly ash pastes modified with micro-size metakaolin subjected to high temperatures. J. Central South Univ. 27(1), 231–241 (2020)

Rashad, A.M.: Metakaolin as cementitious material: history, scours, production and composition—a comprehensive overview. Constr. Build. Mater. 41, 303–318 (2013)

Rashad, A.M.; Hassan, A.A.; Zeedan, S.R.: An investigation on alkali-activated Egyptian metakaolin pastes blended with quartz powder subjected to elevated temperatures. Appl. Clay Sci. 132, 366–376 (2016)

Kenne Diffo, B.; Elimbi, A.; Cyr, M.; Dika Manga, J.; Tchakoute Kouamo, H.: Effect of the rate of calcination of kaolin on the properties of metakaolin-based geopolymers. J. Asian Ceram. Soc. 3(1), 130–138 (2015)

Rashad, A.M.; Zeedan, S.R.; Hassan, A.A.: Influence of the activator concentration of sodium silicate on the thermal properties of alkali-activated slag pastes. Constr. Build. Mater. 102, 811–820 (2016)

Memon, A.; Radin, S.; Zain, M.F.M.; Trottier, J.-F.: Effects of mineral and chemical admixtures on high-strength concrete in seawater. Cem. Concr. Res. 32(3), 373–377 (2002)

Rashad, A.M.; Ouda, A.S.: Effect of tidal zone and seawater attack on high-volume fly ash pastes enhanced with metakaolin and quartz powder in the marine environment. Microporous Mesoporous Mater. 324, 111261 (2021)

Bernal, S.A.; Provis, J.L.; Rose, V.; De Gutierrez, R.M.: Evolution of binder structure in sodium silicate-activated slag-metakaolin blends. Cement Concr. Compos. 33(1), 46–54 (2011)

Kramar, S.; Šajna, A.; Ducman, V.: Assessment of alkali activated mortars based on different precursors with regard to their suitability for concrete repair. Constr. Build. Mater. 124, 937–944 (2016)

Deb, P.S.; Nath, P.; Sarker, P.K.: The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater. Des. 62, 32–39 (2014)

Ye, H.; Fu, C.; Yang, G.: Alkali-activated slag substituted by metakaolin and dolomite at 20 and 50 °C. Cem. Concr. Compos. 105, 103442 (2020)

Li, Z.; Nedeljković, M.; Chen, B.; Ye, G.: Mitigating the autogenous shrinkage of alkali-activated slag by metakaolin. Cem. Concr. Res. 122, 30–41 (2019)

Akçaözoğlu, S.; Ulu, C.: Recycling of waste PET granules as aggregate in alkali-activated blast furnace slag/metakaolin blends. Constr. Build. Mater. 58, 31–37 (2014)

Burciaga-Díaz, O.; Escalante-García, J.I.; Arellano-Aguilar, R.; Gorokhovsky, A.: Statistical analysis of strength development as a function of various parameters on activated metakaolin/slag cements. J. Am. Ceram. Soc. 93(2), 541–547 (2010)

Burciaga-Díaz, O.; Gómez-Zamorano, L.Y.; Escalante-García, J.I.: Influence of the long term curing temperature on the hydration of alkaline binders of blast furnace slag-metakaolin. Constr. Build. Mater. 113, 917–926 (2016)

Li, Y.; Sun, Y.: Preliminary study on combined-alkali–slag paste materials. Cem. Concr. Res. 30(6), 963–966 (2000)

Dong, M.; Elchalakani, M.; Karrech, A.: Curing conditions of alkali-activated fly ash and slag mortar. J. Mater. Civ. Eng. 32(6), 04020122 (2020)

Qureshi, M.N.; Ghosh, S.: Effect of curing conditions on the compressive strength and microstructure of alkali-activated GGBS paste. Int. J. Eng. Sci. Invent. 2(2), 24–31 (2013)

Karim, M.R.; Hossain, M.M.; Elahi, M.M.A.; Zain, M.F.M.: Effects of source materials, fineness and curing methods on the strength development of alkali-activated binder. J. Build. Eng. 29, 101147 (2020)

Collins, F.; Sanjayan, J.: Microcracking and strength development of alkali activated slag concrete. Cem. Concr. Compos. 23(4–5), 345–352 (2001)

Palomo, A.; Blanco-Varela, M.T.; Granizo, M.; Puertas, F.; Vazquez, T.; Grutzeck, M.: Chemical stability of cementitious materials based on metakaolin. Cem. Concr. Res. 29(7), 997–1004 (1999)

Li, X.; Rao, F.; Song, S.; Ma, Q.: Deterioration in the microstructure of metakaolin-based geopolymers in marine environment. J. Mater. Res. Technol. 8(3), 2747–2752 (2019)

Yahya, Z.; Abdullah, M.M.A.B.; Jing, L.Y.; Li, L.-Y.; Abd Razak, R.: Seawater Exposure Effect on Fly Ash based Geopolymer Concrete with Inclusion of Steel Fiber. IOP Publishing, Bristol (2020)

Samimi, K.; Kamali-Bernard, S.; Maghsoudi, A.A.: Durability of self-compacting concrete containing pumice and zeolite against acid attack, carbonation and marine environment. Constr. Build. Mater. 165, 247–263 (2018)

Ganjian, E.; Pouya, H.S.: The effect of Persian Gulf tidal zone exposure on durability of mixes containing silica fume and blast furnace slag. Constr. Build. Mater. 23(2), 644–652 (2009)

Odriozola, M.A.B.; Gutiérrez, P.A.: Comparative study of different test methods for reinforced concrete durability assessment in marine environment. Mater. Struct. 41(3), 527–541 (2008)

Zuquan, J.; Xia, Z.; Tiejun, Z.; Jianqing, L.: Chloride ions transportation behavior and binding capacity of concrete exposed to different marine corrosion zones. Constr. Build. Mater. 177, 170–183 (2018)

Stark, J.; Ludwig, H.-M.: Freeze-thaw and freeze-deicing salt resistance of concretes containing cement rich in granulated blast furnace slag. Mater. J. 94(1), 47–55 (1997)

Haha, M.B.; Lothenbach, B.; Le Saout, G.; Winnefeld, F.: Influence of slag chemistry on the hydration of alkali-activated blast-furnace slag—part II: effect of Al2O3. Cem. Concr. Res. 42(1), 74–83 (2012)

Zhang, Z.; Yao, X.; Wang, H.: Potential application of geopolymers as protection coatings for marine concrete III. Field experiment. Appl. Clay Sci. 67, 57–60 (2012)

Peng, H.; Cui, C.; Liu, Z.; Cai, C.; Liu, Y.: Synthesis and reaction mechanism of an alkali-activated metakaolin-slag composite system at room temperature. J. Mater. Civ. Eng. 31(1), 04018345 (2019)

Rashad, A.M.; Zeedan, S.R.; Hassan, H.A.: A preliminary study of autoclaved alkali-activated slag blended with quartz powder. Constr. Build. Mater. 33, 70–77 (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rashad, A.M., Sadek, D.M. An Exploratory Study on Alkali-Activated Slag Blended with Microsize Metakaolin Particles Under the Effect of Seawater Attack and Tidal Zone. Arab J Sci Eng 47, 4499–4510 (2022). https://doi.org/10.1007/s13369-021-06151-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06151-z