Abstract

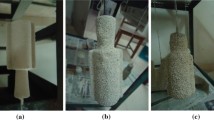

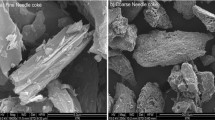

Investment casting (IC) process utilizes a single use ceramic shell as mold for casting. The accuracy and surface finish of the interior of the ceramic shells is transferred to the castings. The quality of the ceramic shell depends upon the constituents and characteristics of the ceramic slurry. The present exploration deals with finding a solution how to maintain the prepared primary slurry characteristics after 24 h duration for future application. The stability of the primary slurry was achieved by forming a thin layer of argon gas over the prepared primary slurry surface so that it is not exposed to atmosphere. The primary slurry properties, i.e., viscosity, density, plate weight and pH value, were determined after 24 h of exposure of the slurry to argon gas. A comparison of the aforementioned slurry characteristics was made between the slurry without (A) and with (B) coverage of argon gas at the top of slurry surface. It was found that the slurries A and B possessed viscosities of 1862 and 1563 cp, densities of 4.31 and 3.74 gm/cm3, plate weights of 0.232 and 0.209 gm/cm2 and pH of 8.3 and 8.9, respectively, at the end of 24 h duration. It shows that argon gas coverlet over the slurry B led to significant improvement in preserving the slurry characteristics. Furthermore, the surface texture of the interior of the primary layer formed using slurry B was better than that by slurry A.

Similar content being viewed by others

References

Clegg, A.J.: Precision casting processes. Pergamon Press, Oxford (1991)

Pattnaik, S.R.; Karunakar, D.B.; Jha, P.K.: Developments in investment casting process—A review. J. Mater. Process. Technol. 212, 2332–2348 (2012)

Pattnaik, S.R.: An investigation on enhancing ceramic shell properties using naturally available additives. Int. J. Adv. Manuf. Technol. (2016). https://doi.org/10.1007/s00170-016-9975-4

Pattnaik, S.R.: Influence of saw dust on the properties of the ceramic shell used in investment casting process. Int. J. Adv. Manuf. Technol. 93(1–4), 691–707 (2017)

Beeley, P.R.; Smart, R.F.: Investment Casting. Institute of Materials, London (1995)

Watts, C.H.: Investment casting method and stucco therefor. U.S. Patent No. 4,689,081 (1987)

Wang, F.; Li, F.; He, B.; Sun, B.: Microstructure and strength of needle coke modified ceramic casting molds. Ceram. Int. 40(1), 479–486 (2014)

Li, Z.; Liu, X.; Lv, K.: Study on the strength of short carbon fiber-reinforced silicon sol shells for the investment casting process. Int. J. Metal. Cast. 14, 432–441 (2020). https://doi.org/10.1007/s40962-019-00362-9

Lu, K.; Liu, X.; Duan, Z.: Effect of firing temperature and time on hybrid fiber-reinforced shell for investment casting. Int. J. Metal. Cast. 13, 666–673 (2019)

Xu, M.; Qing, J.: Effect of firing temperature and duration on fused silica investment shell strength at room temperature. Int. J. Metal. Cast. 13, 923–927 (2019)

Lu, K.; Duan, Z.; Liu, X.: Effect of dispersant on fiber-reinforced shell for investment casting. Int. J. Metal. Cast. 14, 1005–1012 (2020)

Yahaya, B.; Izman, S.; Idris, M.H.; Dambatta, M.S.: Effects of activated charcoal on physical and mechanical properties of microwave dewaxed investment casting moulds. Manuf. Sci. Technol, CIRP J (2016) https://doi.org/10.1016/j.cirpj.2016.01.002

Jia, Q.; Cui, Y.; Yang, R.: A study of two refractories as mould materials for investment casting TiAl based alloys. J. Mater. Sci. 41, 3045–3049 (2006)

Brown, B.: pH Control in Investment Casting Slurries. REMET UK, https://www.remet.com/en/insights/ph-control-investment-casting-slurries.

Davison. G.: LUDOX Colloidal Silica Ceramic Shell Investment Casting, Materials & Packaging Technologies, Technical information, https://dokumen.tips/documents/ludox-colloidal-silica-ceramic-shell-investment-davison-materials-packaging.html.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pattnaik, S., Sutar, M.K. Enhancement of Ceramic Slurry Rheology in Investment Casting Process. Arab J Sci Eng 46, 12065–12076 (2021). https://doi.org/10.1007/s13369-021-05834-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05834-x