Abstract

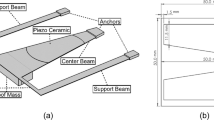

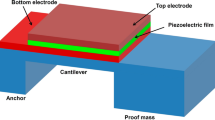

Recently, energy harvesting for battery-operated sensor nodes have received a great deal of attention in boosting their lifespan. Considering green energy sources like vibration, piezoelectric vibrational energy harvesting is an effective technique to provide add-on power to these sensor nodes. High power density at ultra-low frequency is crucial for designing a microcantilever-based piezoelectric energy harvester (PEH). An area optimized with high power efficiency micro-electromechanical system (MEMS) PEH using split proof mass arrangement is reported in this article. The proposed harvester is comprised of alternate layers of copper electrode and Barium Titanate \((BaTiO_3)\) piezoelectric material with tungsten split proof mass arrangement. Finite element method (FEM) simulation is used to evaluate the performance of harvester using unequal weighted proof masses at different lengths of the beam. The optimized split proof mass harvester results in 31 % reduction in resonance frequency compared to conventional single proof mass harvester beam. The maximum output power of 1.6 \(\mu \)W is obtained at 57.1 Hz of resonant frequency with an input acceleration of 1g. The normalized areal and volumetric power density was found to be \(4.44\times 10^{-2} \mu \hbox {W/mm}^2 \cdot \hbox {g}^2 \cdot \hbox {Hz}\) and \(4.95 \mu \hbox {W/mm}^3 \cdot \hbox {g}^2 \cdot \hbox {Hz}\).

Similar content being viewed by others

References

Abdelmoula, H.; Sharpes, N.; Abdelkefi, A.; Lee, H.; Priya, S.: Low-frequency zigzag energy harvesters operating in torsion-dominant mode. Appl. Energy 204, 413–419 (2017)

A. H. Alameh, M. Gratuze, and F. Nabki: Impact of geometry on the performance of cantilever-based piezoelectric vibration energy harvesters, IEEE Sens. J., pp. 1 (2019)

Beeby, S.P.; Tudor, M.J.; White, N.: Energy harvesting vibration sources for microsystems applications. Meas. Sci. Technol. 17(12), R175 (2006)

Challa, V.R.; Prasad, M.; Fisher, F.T.: Towards an autonomous self-tuning vibration energy harvesting device for wireless sensor network applications. Smart Mater. Struct. 20(2), 025004 (2011)

S. S. Chauhan, M. M. Joglekar, and S. K. Manhas: High power density cmos compatible micro-machined mems energy harvester, IEEE Sens. Journal, pp. 1 (2019)

Chen, G.; Ghaed, H.; Haque, R.-U.; Wieckowski, M.; Kim, Y.; Kim, G.; Fick, D.; Kim, D.; Seok, M.; Wise, K. et al.: A cubic-millimeter energy-autonomous wireless intraocular pressure monitor. IEEE International Solid-State Circuits Conference. IEEE 2011, 310–312 (2011)

Elfrink, R.; Renaud, M.; Kamel, T.; De Nooijer, C.; Jambunathan, M.; Goedbloed, M.; Hohlfeld, D.; Matova, S.; Pop, V.; Caballero, L.; et al.: Vacuum-packaged piezoelectric vibration energy harvesters: damping contributions and autonomy for a wireless sensor system. J. Micromech. Microeng. 20(10), 104001 (2010)

Guo, H.; Wen, Z.; Zi, Y.; Yeh, M.-H.; Wang, J.; Zhu, L.; Hu, C.; Wang, Z.L.: A water-proof triboelectric-electromagnetic hybrid generator for energy harvesting in harsh environments. Adv. Energy Mater. 6(6), 1501593 (2016)

Hajati, A.; Kim, S.-G.: Ultra-wide bandwidth piezoelectric energy harvesting. Appl. Phys. Lett. 99(8), 083105 (2011)

Harne, R.L.; Wang, K.: A review of the recent research on vibration energy harvesting via bistable systems. Smart Mater. Struct. 22(2), 023001 (2013)

Ichige, R.; Kuriyama, N.; Umino, Y.; Tsukamoto, T.; Suzuki, T.: Size optimization of metamaterial structure for elastic layer of a piezoelectric vibration energy harvester. Sens. Actuators A: Phys. 318, 112488 (2021)

Jackson, N.; Stam, F.: Sloshing liquid-metal mass for widening the bandwidth of a vibration energy harvester. Sens. Actuators A: Phys. 284, 17–21 (2018)

Jeong, S.; Foo, Z.; Lee, Y.; Sim, J.; Blaauw, D.; Sylvester, D.: A fully-integrated 71 nw cmos temperature sensor for low power wireless sensor nodes. IEEE J. Solid-State Cir. 49(8), 1682–1693 (2014)

Kim, M.; Hoegen, M.; Dugundji, J.; Wardle, B.L.: Modeling and experimental verification of proof mass effects on vibration energy harvester performance. Smart Mater. Struct. 19(4), 045023 (2010)

A. Lei, R. Xu, A. Thyssen, A. C. Stoot, T. L. Christiansen, K. Hansen, R. Lou-Møller, E. V. Thomsen, and K. Birkelund: Mems-based thick film pzt vibrational energy harvester. In 2011 IEEE 24th International Conference on Micro Electro Mechanical Systems, pp. 125–128 (2011)

Mahmoud, H.H.; ElAttar, H.M.; Saafan, A.; ElBadawy, H.: Optimal operational parameters for 5g energy harvesting cognitive wireless sensor networks. IETE Tech. Rev. 34(sup1), 62–72 (2017)

P. Mangaiyarkarasi and P. Lakshmi: Multi-objective optimization of single-layer and multi-layer piezoelectric energy harvester under non-linear multi-mode operation using genetic algorithm. Materials Today: Proceedings (2020)

Morimoto, K.; Kanno, I.; Wasa, K.; Kotera, H.: High-efficiency piezoelectric energy harvesters of c-axis-oriented epitaxial pzt films transferred onto stainless steel cantilevers. Sens. Actuators A Phys. 163(1), 428–432 (2010)

Ou, Q.; Chen, X.; Gutschmidt, S.; Wood, A.; Leigh, N.; Arrieta, A.F.: An experimentally validated double-mass piezoelectric cantilever model for broadband vibration-based energy harvesting. J. Intell. Mater. Syst. Struct. 23(2), 117–126 (2012)

Park, J.C.; Park, J.Y.; Lee, Y.-P.: Modeling and characterization of piezoelectric \( d\_ \)\(33\) -mode mems energy harvester. J. Microelectromech. Syst. 19(5), 1215–1222 (2010)

Quintero, A.V.; Besse, N.; Janphuang, P.; Lockhart, R.; Briand, D.; De Rooij, N.F.: Design optimization of vibration energy harvesters fabricated by lamination of thinned bulk-pzt on polymeric substrates. Smart Mater. Struct. 23(4), (2014)

Roundy, S.; Wright, P.K.; Rabaey, J.: A study of low level vibrations as a power source for wireless sensor nodes. Comput. Commun. 26(11), 1131–1144 (2003)

Song, H.-C.; Kumar, P.; Maurya, D.; Kang, M.-G.; Reynolds, W.T.; Jeong, D.-Y.; Kang, C.-Y.; Priya, S.: Ultra-low resonant piezoelectric mems energy harvester with high power density. J. Microelectromech. Syst. 26(6), 1226–1234 (2017)

Stanton, S.C.; McGehee, C.C.; Mann, B.P.: Reversible hysteresis for broadband magnetopiezoelastic energy harvesting. Appl. Phys. Lett. 95(17), 174103 (2009)

Todaro, M.T.; Guido, F.; Mastronardi, V.; Desmaele, D.; Epifani, G.; Algieri, L.; Vittorio, M.D.: Piezoelectric mems vibrational energy harvesters: advances and outlook. Microelect. Eng. 183–184, 23–36 (2017)

Tsujiura, Y.; Suwa, E.; Kurokawa, F.; Hida, H.; Suenaga, K.; Shibata, K.; Kanno, I.: Lead-free piezoelectric mems energy harvesters of (k, na) nbo3 thin films on stainless steel cantilevers. Jap. J. Appl. Phys. 52(9S1), 09KD13 (2013)

Vullers, R.; van Schaijk, R.; Doms, I.; Van Hoof, C.; Mertens, R.: Micropower energy harvesting. Solid-State Elect. 53(7), 684–693 (2009)

Xu, R.; Kim, S.-G.: Modeling and experimental validation of bi-stable beam based piezoelectric energy harvester. Energy Harv. Syst. 3(4), 313–321 (2016)

Xu, C.; Ren, B.; Liang, Z.; Chen, J.; Zhang, H.; Yue, Q.; Xu, Q.; Zhao, X.; Luo, H.: Nonlinear output properties of cantilever driving low frequency piezoelectric energy harvester. Appl. Phys. Lett. 101(22), 223503 (2012)

Yoon, S.; Sim, J.K.; Cho, Y.-H.: A flexible piezoelectric pulsewave energy harvester for application to high-efficiency multi-functional skin patches. J. Microelectromech. Syst. 25(2), 388–393 (2016)

Zhang, L.; Zhang, B.; Chen, J.; Jin, L.; Deng, W.; Tang, J.; Zhang, H.; Pan, H.; Zhu, M.; Yang, W.; et al.: Lawn structured triboelectric nanogenerators for scavenging sweeping wind energy on rooftops. Adv. Mater. 28(8), 1650–1656 (2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Butram, V., Naugarhiya, A. Performance Enhancement of Piezoelectric MEMS Energy Harvester Using Split Proof Mass for Powering Ultralow Power Wireless Sensor Nodes. Arab J Sci Eng 47, 2755–2762 (2022). https://doi.org/10.1007/s13369-021-05829-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05829-8