Abstract

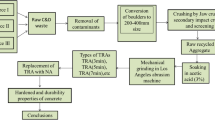

In grinding wheel, the stub portion is unused and dumped after end of its primary purpose. The portion, which is considered as waste, has unused abrasives in it. The present work deals with reusing this abrasive waste as the replacement material for sand in concrete production. Reuse of the crushed vitrified brown alumina abrasive wheel which passes through 80 mesh can be used as a partial replacement for sand in concrete production. Structural properties of the crushed abrasive waste were analysed using X-ray diffraction and scanning electron microscopic analysis. Concrete samples were made with five different replacement ratios of 10%, 20%, 30%, 40% and 50% to replace the fine aggregate(sand) in concrete. Mechanical properties such as compressive, split-tensile, flexural strength and water absorption properties of the prepared concrete were determined. It was found that partial replacement of sand by abrasive waste was able to increase the compressive by 32%, tensile strength by 17% and flexural strength by 14%. Abrasive resistance of the concrete was measured using sand blasting equipment. Concrete with 40% abrasive waste shows around 83% improvement in abrasive resistance. The reuse of abrasive wastes as a partial replacement of sand in concrete is seen to enhance its mechanical properties and enable proper utilisation of these non-biodegradable solid wastes for better environment.

Similar content being viewed by others

References

Kankam, C.K.; Meisuh, B.K.; Sossou, G.; Buabin, T.K.: Stress-strain characteristics of concrete containing quarry rock dust as partial replacement of sand. Case Stud. Constr. Mater. 7, 66–72 (2017)

Mehra, P.; Gupta, R.C.; Thomas, B.S.: Properties of concrete containing jarosite as a partial substitute for fine aggregate. J. Clean. Prod. 120, 241–248 (2016)

Lu, J.; Cong, X.; Li, Y.; Hao, Y.; Wang, C.: High strength artificial stoneware from marble waste via surface modification and low temperature sintering. J. Clean. Prod. 180, 728–734 (2018)

Revathi, P.; Nikesh, P.: Effect of fly-ash on corrosion resistance characteristics of rebar embedded in recycled aggregate concrete. J. Inst. Eng. India Ser. A. 99(3), 473–483 (2018)

Islam, M.R.; Mohsin, M.; Hannan, M.M.A.; Faruque, M.O.; Islam, M.K.; Rahman, M.A.; Shahin, M.A.H.: Strength assessment of concrete cubes containing variable mixtures of Portland cement and granite dust of the Maddhapara mine, NW Bangladesh. Am. J. Civ. Eng. 4(6), 319–325 (2016)

Alves, A.V.; Vieira, T.F.; De Brito, J.; Correia, J.R.: Mechanical properties of structural concrete with fine recycled ceramic aggregates. Constr. Build. Mater. 64, 103–113 (2014)

Elçi, H.: Utilisation of crushed floor and wall tile wastes as aggregate in concrete production. J. Clean. Prod. 112, 742–752 (2016)

Penteado, C.S.G.; De Carvalho, E.V.; Lintz, R.C.C.: Reusing ceramic tile polishing waste in paving block manufacturing. J. Clean. Prod. 112, 514–520 (2016)

Jang, H.S.; So, S.Y.: The properties of cement-based mortar using different particle size of grinding wheel waste insulator powder. J. Build. Eng. 3, 48–57 (2015)

Liu, J.H.; Pei, Z.J.; Fisher, G.R.: Grinding wheels for manufacturing of silicon wafers: a literature review. Int. J. Mach. Tool Manuf. 47(1), 1–13 (2007)

Biao, Z.H.; Tianyu, Y.U.; Wenfeng, D.I.; Xianying, L.I.: Effects of pore structure and distribution on strength of porous Cu–Sn–Ti alumina composites. Chin. J. Aeronaut. 30(6), 2004–2015 (2017)

Cheng, S.; Shui, Z.; Sun, T.; Yu, R.; Zhang, G.; Ding, S.: Effects of fly ash, blast furnace slag and metakaolin on mechanical properties and durability of coral sand concrete. Appl. Clay Sci. 141, 111–117 (2017)

Sabarinathan, P.; Annamalai, V.E.; Kumar, S.S.; Kennedy, A.X.: A study on recovery of alumina grains from spent vitrified grinding wheel. J. Mater. Cycles Waste Manag. 21(1), 156–165 (2019)

Babu, M.K.; Chetty, O.K.: A study on recycling of abrasives in abrasive water jet machining. Wear 254(7–8), 763–773 (2003)

Sabarinathan, P.; Annamalai, V.E.; Kennedy, A.X.: On the use of grains recovered from spent vitrified wheels in resinoid applications. J. Mater. Cycles Waste Manag. 22(1), 197–206 (2020)

Sua-iam, G.; Makul, N.: Incorporation of high-volume fly ash waste and high-volume recycled alumina waste in the production of self-consolidating concrete. J. Clean. Prod. 159(2017), 194–206 (2017)

Ho, C.H.; Lo, H.M.; Lin, K.L.; Lan, J.Y.: Characteristics of water-retaining porous ceramics with sandblasting waste. Constr. Build. Mater. 157, 75–82 (2017)

Ren, Q.; Jiang, Z.; Li, H.; Zhu, X.; Chen, Q.: Fresh and hardened properties of self-compacting concrete using silicon carbide waste as a viscosity-modifying agent. Constr. Build. Mater. 200, 324–332 (2019)

He, Z.; Chen, X.; Cai, X.: Influence and mechanism of micro/nano-mineral admixtures on the abrasion resistance of concrete. Constr. Build. Mater. 197(2019), 91–98 (2019)

ASTM C33: Standard Specification for Concrete Aggregates. ASTM International, West Conshohocken (2003)

EN, B.: 12390-3. Testing Hardened Concrete; Part 3: Compressive Strength of Test Specimens. British Standards Institution (2002)

Standard, L.P.: E397-1993. OPC Concrete: Determination of Elastic Modulus in Compression (1993)

EN, B.: 12390-6 Testing Hardened Concrete. Tensile Splitting Strength of Test Specimens. British Standard Institution, London (2009)

ASTM C418: Standard Test Method for Abrasion Resistance of Concrete by Sandblasting. ASTM International, West Conshohocken (2012)

ASTM C642-97: Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International, West Conshohocken (2004)

Chauruka, S.R.; Hassanpour, A.; Brydson, R.; Roberts, K.J.; Ghadiri, M.; Stitt, H.: Effect of mill type on the size reduction and phase transformation of gamma alumina. Chem. Eng. Sci. 134, 774–783 (2015)

Passos, E.R.; Rodrigues, J.A.: The influence of titanium and iron oxides on the coloring and friability of the blue fired aluminum oxide as an abrasive material. Ceramica. 62(361), 38–44 (2016)

Kang, X.; Lei, H.; Xia, Z.: A comparative study of modified fall cone method and semi-adiabatic calorimetry for measurement of setting time of cement-based materials. Constr. Build. Mater. 248(2020), 118634 (2020)

Xu, J.; Xiao, C.; Wu, H.N.; Kang, X.: Reuse of Excavated clayey silt in cement–fly ash–bentonite hybrid back-fill grouting during shield tunneling. Sustainability 12(3), 1017 (2020)

Sabarinathan, P.; Annamalai, P.V.E.: Removal of aluminosilicate bond and process optimization on recovery of sol gel alumina abrasive grain from abrasive industry waste. SILICON 13, 495–505 (2021)

Kang, X.; Gan, Y.; Chen, R.; Zhang, C.: Sustainable eco-friendly bricks from slate tailings through geopolymerization: synthesis and characterization analysis. Constr. Build. Mater. 278, 122337 (2021)

Mohammadhosseini, H.; Lim, N.H.A.S.; Tahir, M.M.; Alyousef, R.; Alabduljabbar, H.; Samadi, M.: Enhanced performance of green mortar comprising high volume of ceramic waste in aggressive environments. Constr. Build. Mater. 212, 607–617 (2019)

Aggarwal, Y.; Siddique, R.: Microstructure and properties of concrete using bottom ash and waste foundry sand as partial replacement of fine aggregates. Constr. Build. Mater. 54, 210–223 (2014)

Arumugam, K.; Ilangovan, R.; Manohar, J.D.: A study on characterization and use of pond ash as fine aggregate in concrete. Int. j. civ. struct. eng. res. 2(2), 466 (2011)

Foti, D.; Cavallo, D.: Mechanical behavior of concretes made with non-conventional organic origin calcareous aggregates. Constr. Build. Mater. 179, 100–106 (2018)

Ramakrishnan, K.; Pugazhmani, G.; Sripragadeesh, R.; Muthu, D.; Venkatasubramanian, C.: Experimental study on the mechanical and durability properties of concrete with waste glass powder and ground granulated blast furnace slag as supplementary cementitious materials. Constr. Build. Mater. 156(2017), 739–749 (2017)

Gopalan, M.K.: Sorptivity of fly ash concretes. Cem Concr Res. 26(8), 1189-l197 (1996)

Sabarinathan, P.; Annamalai, V.E.; Rajkumar, K.: Sustainable application of grinding wheel waste as abrasive for abrasive water jet machining process. J. Clean. Prod. 261, 121225 (2020)

Gupta, M.; Kumar, M.: Effect of nano silica and coir fiber on compressive strength and abrasion resistance of concrete. Constr. Build. Mater. 226, 44–50 (2019)

Du, S.; Jiang, Y.; Zhong, J.; Ge, Y.; Shi, X.: Surface abrasion resistance of high-volume fly ash concrete modified by graphene oxide: macro-and micro-perspectives. Constr. Build. Mater. 237, 117686 (2020)

Acknowledgements

This project was funded by the Department of Science and Technology, Government of India, under the Technology Systems Development Programme (TSDP) for Waste management [Grant No. DST/TSG/WM/2015/567/G].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sabarinathan, P., Annamalai, V.E. & Sangeetha, P. Mechanical and Abrasion Resistance Properties of Concrete Containing Recycled Abrasive Waste as Partial Replacement of Fine Aggregate. Arab J Sci Eng 46, 10943–10952 (2021). https://doi.org/10.1007/s13369-021-05649-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05649-w