Abstract

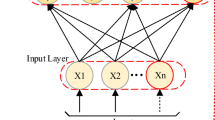

In the process of directional well drilling, the control of build-up rate of the drilling tool assembly with bottom hole stabilizer is the key to the control of the drilling trajectory, and the prediction of the build-up rate is the precondition of the build-up control. Because the prediction of build-up rate is affected by many factors, it is a complicated nonlinear problem influenced by many variables. It is difficult to accurately describe the specific relationship between build-up rate and many influencing variables with quantitative relations. Therefore, this paper proposes a new method to predict the build-up rate based on back-propagation (BP) neural network optimized by genetic algorithm. Firstly, the influence factors of build-up rate are selected as the input of the model, and the output is the actual build-up rate. Then, the model seeks the global threshold weight of the neural network through genetic algorithm and constructs the prediction model. The numerical test results of drilling data in an oilfield show that this method is 0.9176 in MSE evaluation index, which is better than BP neural network, support vector regression, ridge regression, radical basis function neural network and other machine learning methods. This method is not restricted by the guide structure and principle of the tool, making that the build-up rate may be calculated according to the measured real-time data. It can be used as a model for popularization and application in engineering applications, which can effectively improve drilling efficiency and reduce drilling costs.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are included in the manuscript.

References

Liu, Y.; Chen, S.Q.; Guan, B.; Xu, P.: Layout optimization of large-scale oil-gas gathering system based on combined optimization strategy. Neurocomputing 332, 159–183 (2019)

Li, C.: Condition recognition of liquid pipeline based on optimized BP artificial neural network. J. Petrochem. Univ. 31(6), 73–81 (2018)

Du, P.: Steady-state operation optimization of pipeline network based on dynamic programming method and advanced genetic algorithm. Oil Gas Storage Transp. 37(3), 285–290 (2018)

Wang, Z.H.; Lin, X.Y.; Yu, T.Y.: Formation and rupture mechanisms of visco-elastic interfacial films in polymer-stabilized emulsions. J. Dispersion Sci. Technol. 40(4), 612–626 (2019)

Yang, E.L.: Research and application of microfoam selective water plugging agent in shallow low-temperature reservoirs. J. Pet. Eng. 193, 107354 (2019)

Jing, J.Q.: Rheological behavior of heavy crude and its emulsions. Pet. Sci. Technol. 38(5), 440–446 (2020)

Wang, J.L.; Deng, C.G.: Regression analysis and application of the build-up rate of drilling assemblies. Oil Drill. Prod. Technol. 14(1), 25–30 (1992)

Su, Y.N.; Zhou, Y.H.: Methods of prediction bit trajectory and their applications in directional drilling. Acta Petrol. Sin. 12(3), 139–150 (1991)

Yin, S.; Fend, D.; Li, X.M.: Analysis and foundation on the model of longitudinal vibration of drilling string. J. Vib. 25(S), 906–908 (2006)

Feng, D.; Xiao, A.; Liao, Z.J.: Loading and axial deformation of finite element analysis of down-hole strings used for hydraulic fracturing. Appl. Mech. Mater. 318, 3–6 (2013)

Karisson, H.; Cobbley, R.; Jaques, G.E.: Performance Drilling Optimization. SPE/IADC 13474 (1985)

Liu, X.S.; He, S.S.; Zhou, Y.: Study on geometric build-up slope of guide drill. Acta Petrol. Sin. 25(6), 83–87 (2004)

Liu, X.: A practical method for calculating geometric build-up slope of guide drill. Nat. Gas. Ind. 25(11), 50–52 (2005)

Su, Y.N.: Limit curvature method and its application. Acta Petrol. Sin. 18(3), 110–113 (1997)

Hua, Y.: Force Analysis and Slope Prediction of Single—Bent Screw Drill Assembly. Yangtze University, Jingzhou (2018)

Shi, Y.C.; Guan, Z.C.; Zhao, H.S.; Huang, G.L.: A new method for prediction of bottom hole assembly building slope. J. China Univ. Petrol. 41(01), 85–89 (2017)

Liu, G.H.; Liu, W.; Liu, Z.; Wu, Z.J.: Four factors and three levels orthogonal regression analysis were used to predict the build rate of drilling tools. J. Petrol. Nat. Gas 32(03), 108–112 (2010)

Zhang, H.; Tu, Y.L.; Feng, D.: Research on prediction method of building-up rate of deflecting tools based on Kriging surrogate model. Sci. Technol. Eng. 17(3), 61–68 (2017)

Li, Z.Y.; Yi, Y.Z.: Quantitative relation between learning ability and generalization ability of BP neural network. Acta Electron. Sin. 15(09), 1341–1344 (2003)

Mends, R.; Cortez, P.; Rocha, M.; Neves, J.: Partical swarms for feedforward neural network training. In: Proceeding of the 2002 International Joint Conference on Neural Networks 2002, 1895–1899 (2002)

Chen, H.; Wang, Q.; Liu, X.K.: Research on wireless sensor network data fusion algorithm based on PSO-BP. Comput. Meas. Control 22(4), 1212–1214 (2014)

Benvidi, A.; Abbasi, S.; Gharaghani, S.: Spectrophotometric determination of synthetic colorants using PSO-GA-ANN. Food Chem. 220, 377–384 (2017)

Gao, X.D.; Zhang, Y.X.: Prediction model of weld width during high-power disk laser welding of 304 austenitic stainless steel. Int. J. Precis. Eng. Manuf. 15(3), 399–405 (2014)

Simon, H.: Principle of Neural Network. China Machine Press, Beijing (2004)

Yue, C.W.; Li, N.T.; Hai, L.W.: Inflation forecast based on BP neural network model. Adv. Mater. Res. 3326(989), 5536–5539 (2014)

Cui, J.Y.; Han, X.P.; Lu, L.Y.: The economic restructuring under new industry: a model for leapfrogging development and the shift of leadership. Int. J. Mod. Phys. 30(7), 27–35 (2019)

Engelbrecht, P.: Introduction to Computational Intelligence. Tsinghua University Press, Beijing (2010)

Li, Q.; Wang, J.; Tao, H.: The prediction model of warfarin individual maintenance dose for patients undergoing heart valve replacement, based on the back propagation neural network. Clin. Drug Investig. 15(6), 3516–3526 (2019)

Mohamed, L.S.; Rovetta, S.; Ton, D.D.: A neural-network-based model predictive control of three-phase inverter with an output LC filter. IEEE Access 7, 124737–124749 (2019)

Guo, J.B.; Qian, C.; Zhu, X.K.: Research on vibration prediction of hydraulic unit based on GA-BP. Hydropower Sci. 38(10), 133–135 (2020)

Wang, Q.; Bao, W.L.: Research on drilling robot arm error compensation based on GA-BP algorithm. Min. Mach. 48(11), 1–5 (2020)

Zhang, Q.X.; Zhu, X.D.: Sequential iris quality evaluation algorithm based on GA-BP neural network. J. Jilin Univ. (Sci. Edn.) 58(06), 1382–1390 (2020)

Zhang, J.H.; Wang, F.F.; Wu, Y.Y.: Application of GA-BP neural network in fault monitoring system of Belt Conveyor. Coal Mine Mach. 41(12), 129–131 (2020)

Ge, X.Y.; Wang, Y.H.; Zhou, X.: Application of GA-BP neural network in NB-iot water quality monitoring system. Mod. Electron. Tech. 43(24), 33–37 (2020)

Acknowledgements

This research is supported by the National Natural Science Foundation of China Nos. 61733016, 41672155. Hubei Provincial Natural Sciences Foundation Outstanding Youth Fund. No.2018CFA092.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Qiu, W., Wen, G. & Liu, H. A Back-Propagation Neural Network Model Based on Genetic Algorithm for Prediction of Build-Up Rate in Drilling Process. Arab J Sci Eng 47, 11089–11099 (2022). https://doi.org/10.1007/s13369-021-05634-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05634-3