Abstract

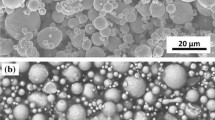

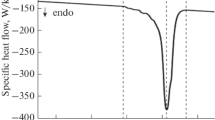

Dewaxing is an intermediate step in investment casting which can determine the properties of final metallic product and is strongly dependent on the properties of pattern wax. Processing of pattern wax composites with the conventionally available heating processes is energy intensive and requires high processing time, thus resulting in the lower processing rate at larger scale. Use of microwave technology for the dewaxing study is highly attractive alternative owing to the advantage of energy-efficient processing. The processing time of pattern wax composite of paraffin wax, bitumen, polyethylene and EVA in microwaves oven as a function of susceptor has been investigated. Carbon black was used as microwave susceptor in wax composites at several weight percentages. The efficient processing and melting behavior of pattern wax composite utilizing microwave dewaxing, thanks to the creation of heat sensitive sites within the pattern wax composite by the susceptor material, were analyzed in this study. FTIR-ATR, rheometer, TGA, DSC, UTM, SEM and OM were used to study the behavior of the wax composite. With the increase in the susceptor (CB) loading from 0.15 to 0.75%, an increase in the thermal stability of 6.86% was observed as depicted by the increase in the on-set temperature of the specimens. 71.9% decrease in the melt flow time of pattern wax composite was observed with the incorporation of 1.5% of CB as compared to reference specimen which manifested an inverse relationship between susceptor loading and processing time in the presence of microwave.

Similar content being viewed by others

References

Tas, S.; Inem, B.: Conversion of an Investment Casting Sprue Wax to a Pattern Wax by the Modification of its Properties. Mater. Des. 25, 499–505 (2004)

Krupa, I.; Mikova, G.: Phase change materials based on low-density polyethylene / paraffin wax blends. Eur. Polym. J. 43, 4695–4705 (2007)

Mykhailyk, V.; Korinchevska, T.; Vorobiev, L.; Dekusha, L.: Specific heat capacity and thermal conductivity of heat storage materials based on paraffin, brown-coal wax and polyethylene wax. Probl. Energ. Reg. 2, 38–46 (2014)

Akishino, J.K.; Cerqueira, D.P.; Silva, G.C.; Swinka-filho, V.; Munaro, M.: Morphological and thermal evaluation of blends of polyethylene wax and paraffin. Thermochim. Acta. 626, 9–12 (2016)

Biernacki, R.; Haratym, R.; Bałkowiec, A.; Wawulska-Marek, P.; Matysiak, H.; Zdunek, J.; Kurzydłowski, K.J.: Evaluation of physical properties of wax mixtures obtained from recycling of patterns used in precision casting. Arch. Metall. Mater. 60, 345–349 (2015)

Brum, F.J.B.; Amico, S.C.; Vedana, I.; Spim, J.A.: Microwave dewaxing applied to the investment casting process. J. Mater. Process. Technol. 209, 3166–3171 (2009)

Haque, K.E.: Microwave energy for mineral treatment processes: a brief review. Int. J. Miner. Process. 57, 1–24 (1999)

Wu, K.; Park, H.; Willert-porada, M.: Pyrolysis of polyurethane by microwave hybrid heating for the processing of NiCr foams. J. Mater. Process. Tech. 212, 1481–1487 (2012)

Yarlagadda, P.K.D.V.; Chai, T.C.: An investigation into welding of engineering thermoplastics using focused microwave energy. J. Mater. Process. Technol. 74, 199–212 (1998)

Kathirgamanathan, P.: Microwave welding of thermoplastics using inherently conducting polymers. Polymer (Guildf). 34, 3105–3106 (1993)

Vafudan, V.K.; Varadan, V.V.: Microwave joining and repair of composite materials. Polym. Eng. Sci. 31, 470–486 (1991)

Wise, R.; Froment, I.: Microwave welding of thermoplastics. J. Mater. Sci. 36, 5935–5954 (2001)

Gill, Y.Q.; Irfan, M.S.; Khan, F.H.; Saeed, F.; Ehsan, H.; Shakoor, A.: Carbon black/nickel hybrid filler reinforced conductive polypropylene composites. Mater. Res. Express. 6, 1–9 (2019)

Lei, K.F.; Ahsan, S.; Budraa, N.; Li, W.J.; Mai, J.D.: Microwave bonding of polymer-based substrates for potential encapsulated micro / nanofluidic device fabrication. Sens. Actuators A Phys. 114, 340–346 (2004)

Clarke, J.; Harper, J.F.; Price, D.M.; Zhang, J.: Effect of carbon black grade on the microwave heating of high- density polyethylene. J. Appl. Polym. Sci. 31, 1–9 (2007)

Gill, Y.Q.; Jin, J.; Song, M.: Melt flow behavior of high density polyethylene nanocomposites with 1D, 2D and 3D nanofillers. Nanocomposites 1, 160–169 (2015)

Yahaya, B.; Izman, S.; Idris, M.H.; Dambatta, M.S.: Effects of activated charcoal on physical and mechanical properties of microwave dewaxed investment casting moulds. J. Manuf. Sci. Technol. 13, 97–103 (2016)

Wu, C.; Benatar, A.: Microwave welding of high density polyethylene using intrinsically conductive polyaniline. Polym. Eng. Sci. 37, 738–743 (1997)

Adolfo, B. B.; Begoña, G.; Chris, H.; Thomas, B.; Peter, M. Selective heating applications for the processing of polymer-polymer materials. In: ECCM 2012 - Composites at Venice, Proceedings of the 15th European Conference on Composite Materials (2012)

Bayerl, T.; Duhovic, M.; Mitschang, P.; Bhattacharyya, D.: The heating of polymer composites by electromagnetic induction: a review. Compos. Part A Appl. Sci. Manuf. 57, 27–40 (2014)

Danko, G.A.; Silberglitt, R.; Colombo, P.; Pippel, E.; Woltersdorf, J.: Comparison of microwave hybrid and conventional heating of preceramic polymers to form silicon carbide and silicon oxycarbide ceramics. J. Am. Ceram. Soc. 83, 1617–1625 (2000)

Ravindra, I.B.; Narendranath, S.; Srinath, M.S.: Optimization of parameters influencing tensile strength of inconel-625 welded joints developed through microwave hybrid heating. Mater. Today 5, 7659–7667 (2018)

Gill, Y.Q.; Sajid, M.; Ehsan, H.; Abid, U.: Effect of nano-susceptor material addition on the microwave sintering of polypropylene. Pak. J. Engg. Appl. Sci. 24, 88–96 (2019)

Jamroz, N.U.: Determination of vinyl acetate (VA) content of ethylene-vinyl acetate (EVA) copolymers in thick films by infrared spectroscopy. J. Chem. Soc. Pakistan. 25, 84–87 (2003)

Corrales, T.; Catalina, F.; Peinado, C.; Allen, N.S.; Fontan, E.: Photooxidative and thermal degradation of polyethylenes: interrelationship by chemiluminescence, thermal gravimetric analysis and FTIR data. J. Photochem. Photobiol. A Chem. 147, 213–224 (2002)

Krupa, I.; Luyt, A.S.: Physical properties of blends of LLDPE and an oxidized paraffin wax. Polymer (Guildf). 42, 7285–7289 (2001)

Hong, Y.: Encapsulated nanostructured phase change materials for thermal management (2011)

Zhang, Z.; Zhang, N.; Peng, J.; Fang, X.; Gao, X.; Fang, Y.: Preparation and thermal energy storage properties of paraffin/expanded graphite composite phase change material. Appl. Energy 91(1), 426–431 (2012)

Neto, J.M.G.; Ferreira, G.F.L.; Ribeiro Santos Jr., J.; Cunha, H.N.; Dantas, I.F.; Bianchi, R.F.: Complex conductance of carnauba wax/polyaniline composites. Brazilian J. Phys. 33, 371–375 (2003)

Mhike, W.; Focke, W.W.; Mofokeng, J.P.; Luyt, A.S.: Thermally conductive phase-change materials for energy storage based on low-density polyethylene, soft fischer-tropsch wax and graphite. Thermochim. Acta 527, 75–82 (2012)

Yang, C.; Navarro, M.E.; Zhao, B.; Leng, G.; Xu, G.; Wang, L.; Jin, Y.; Ding, Y.: Thermal conductivity enhancement of recycled high density polyethylene as a storage media for latent heat thermal energy storage. Sol. Energy Mater. Sol. Cells 152, 103–110 (2016)

Erliyanti, N.K.; Sangian, H.F.; Susianto, S.; Altway, A.: The preparation of fixed carbon derived from waste tyre using pyrolysis. St. Cerc. St. CICBIA 16, 343–352 (2015)

Brown, M. E.; Gallagher, P. K.: Handbook of Thermal Analysis and Calorimetry. Elsevier Science, Vol. 2, Chapter 3, pp. 113 (2003)

Savetlana, S.; Zulhendri, I. S.; Saputra, F. A.: The effect of carbon black loading and structure on tensile property of natural rubber composite. In: IOP Conf. Series: Materials Science and Engineering, 223, 012009 (2017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gill, Y.Q., Saeed, F., Shoukat, M.H. et al. A Study on the Dewaxing Behavior of Carbon-Black-Modified LDPE–Paraffin Wax Composites for Investment Casting Applications. Arab J Sci Eng 46, 6715–6725 (2021). https://doi.org/10.1007/s13369-021-05406-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05406-z