Abstract

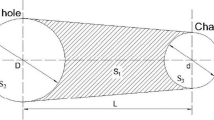

A double wedge cut was used to improve the cut effects in the medium-depth hole blasting of rock roadways. First, the cavity formation mechanisms of single wedge cut and double wedge cut were analysed theoretically. The results show that the cavity formation resistance of the second-order wedge cut is reduced by the first-order wedge cut. Second, simulations of the two cut modes were conducted, which visualize the stress wave evolution and indicate that the stress wave of the first-order cut holes can cause pre-damage to the rock mass in the second-order cut cavity. A comparison of the stress field distribution shows that the first-order cut holes significantly increase the stress field intensity within 0 ~ 1.6 m to enhance the failure of the rock mass in the first-order cut cavity. Hence, the rock mass in the first-order cut cavity can easily be thrown out to create a new free face, which reduces the clamping effect of the second-order wedge cut and exacerbates the tensile failure of the rock mass in the second-order cut cavity. Thus, the difficulty of second-order wedge cut is reduced. Finally, blasting experiments were performed in a rock roadway. Using the double wedge cut, the average footage increased by 0.31 m, the average utilization rate of blastholes increased by 12.4%, and the average specific charge decreased by 0.20 kg·m−3, which proves the superiority of this cut mode.

Similar content being viewed by others

References

Yilmaz, O.; Unlu, T.: Three dimensional numerical rock damage analysis under blasting load. Tunnell. Underground Space Technol. 38, 266–278 (2013)

Liu, Z.G.; Cao, A.Y.; Chen, M.; Liu, G.L.; Liu, J.X.: Experimental research on stress relief of high-stress coal based on noncoupling blasting. Arab. J. Sci. Eng. 43, 3717–3724 (2018)

An, H.M.; Liu, H.Y.; Han, H.Y.; Zheng, X.; Wang, X.G.: Hybrid finite-discrete element modelling of dynamic fracture and resultant fragment casting and muck-piling by rock blast. Comput. Geotech. 81, 322–345 (2017)

Zhao, Z.; Zhang, Y.; Bao, H.: Tunnel blasting simulations by the discontinuous deformation analysis. Int. J. Computa. Methods 8(2), 277–292 (2011)

Yue, Z.W.; Qiu, P.; Wang, X.; Song, Y.; Yu, Q.: Notched-borehole cut blasting study by the method of dynamic caustics. J. China Coal Mine 41(4), 858–863 (2016)

Xie, L.X.; Lu, W.B.; Zhang, Q.B.; Jiang, Q.H.; Chen, M.; Zhao, J.: Analysis of damage mechanisms and optimization of cut blasting design under high in situ stresses. Tunnell. Underground Space Technol. 66, 19–33 (2017)

Huang, B.L.: Progress on the theory and technique of cutting blasting rock drivage. China Min. Magazine 23(10), 103–106 (2014)

Zhang, Z.R.; Yang, R.S.: Multi-step cutting technology and its application in rock roadways. Chinese.J. Rock Mech. Eng. 30(3), 551–559 (2019)

Shapiro, V.Y.: Efficiency of cut configuration in driving tunnels with a set of deep blast holes. Soviet Min. Sci. 25(4), 379–386 (1989)

Dai, J.; Du, X.L.: Research on blasting parameters of wedge-shaped cutting for rock tunnel. Min. Res. Develop. 32(2), 90–93 (2011)

Xiong, H.M.; Cheng, G.H.; Liao, R.F.; Lu, H.P.; Luo, J.: Influencing factors analysis of wedge slotting blasting based on analytical hierarchy process. Eng. Blast. 17(4), 26–30 (2011)

Wang, Z.K.; Gu, X.W.; Zhang, W.L.; Xie, Q.K.; Xu, X.C.; Wang, Q.: Analysis of the cavity formation mechanism of wedge cut blasting in hard rock. Shock Vibr. 2019, 1–10 (2019)

Yang, D.Q.; Wang, X.G.; Wang, Y.J.; An, H.M.; Lei, Z.: Experiment and analysis of wedge cutting angle on cutting effect. Adv. Civil Eng. 2020, 1–16 (2020)

Liao, T.; Pu, C.J.; Wang, J.Q.; Jiang, R.; Yang, X.; Chen, X.F.: Model experiment and analysis of wedge-shaped cutting blasting with cutting seam cartridge in rock tunnel. Metal Mine 44(2), 40–44 (2015)

Lou, X.M.; Wang, B.; Wu, E.; Sun, M.W.; Zhou, P.; Wang, Z.C.: Theoretical and numerical research on V-cut parameters and auxiliary cut hole criterion in tunnelling. Adv. Mater. Sci. Eng. 2020, 1–13 (2020)

Yang, G.L.; Feng, D.K.; Yi, W.H.; Gao, Y.; Zhou, Y.L.: Numerical analysis of comparison of cavities formation by different cutting methods. Blasting 32(2), 59–63 (2015)

Gong, M.; Wen, B.; Wang, H.: Influence of cut parameters on blasting effect in rock roadway of coal mine. Explos. Shock Waves 35(4), 576–584 (2015)

Hu, J.H.; Yang, C.; Zhou, K.P.; Zhou, B.R.; Zhang, S.G.: Temporal-spatial evolution and application of blasting cavity of single wedge cutting. J. Central South Univ. Sci. Technol. 48(12), 3309–3315 (2017)

Gao, Q.D.; Lu, W.B.; Leng, Z.D.; Yang, Z.W.; Yan, P.; Chen, M.: Optimization of cut-hole’s detonating position in tunnel excavation. J. Vibr. Shock 37(9), 8–16 (2018)

Zong, Q.; Liu, Q.H.: Application research on cutting technology of mid-deep hole blasting in coal mine rock tunnel. Blasting 27(4), 35–39 (2010)

Wang, D.S.; Gong, M.; Wang, Z.X.; Zhang, W.Z.: Blast stress field of linear explosive charge and its application to medium-depth hole blasting in underground mine. Explos. Shock Waves 31(4), 355–360 (2011)

Chen, W.; Ma, H.H.; Shen, Z.W.; Wang, D.B.: Experiment research on the rock blasting effect with radial jet cracker. Tunnell. Underground Space Technol. 49, 249–252 (2015)

Chakraborty, A.K.; Pal Roy, P.; Jethwa, J.L.: Blast performance in small tunnels - a critical evaluation in underground metal mines. Tunnell. Underground Space Technol. 13(3), 331–339 (1998)

Pei, Q.; Chen, J.H.: Design of combination of smooth blasting and double-wedge cut for roadway excavation. Min. Res. Develop. 29(2), 75–77 (2009)

Wu, E.; Chen, B.G.; Wang, Z.C.; Li, C.: Test on duplex wedge cut with center hole cutting method used in tunneling. Min. Eng. 14(5), 50–53 (2016)

Ding, Z.W.; Jia, J.D.; Li, X.F.; Li, J.; Li, Y.L.; Liao, J.L.: Experimental study and application of medium-length hole blasting technique in coal-rock roadway. Energy Sci. Eng. 8(5), 1554–1566 (2020)

Si, X.F.; Gong, F.Q.; Li, X.B.; Wang, S.Y.; Luo, S.: Dynamic Mohr–Coulomb and Hoek–Brown strength criteria of sandstone at high strain rates. Int. J. Rock Mecha. Min. Sci. 115, 48–59 (2019)

Yang, J.H.; Lu, W.B.; Li, P.; Yan, P.: Evaluation of rock vibration generated in blasting excavation of deep-buried tunnels. KSCE J. Civil Eng. 22(7), 2593–2608 (2018)

Wang, Z.L.; Huang, Y.P.; Xiong, F.: Three-dimensional numerical analysis of blast-induced damage characteristics of the intact and jointed rock mass. Comput. Mater. Continua. 60(3), 1189–1206 (2019)

Xia, W.J.; Lu, W.B.; Li, R.Z.; Chen, M.; Lei, Z.: Effect of water-decked blasting on rock fragmentation energy. Shock Vibr. 2020, 1–11 (2020)

Parviz, M.; Aminnejad, B.; Fiouz, A.: Numerical simulation of dynamic response of water in buried pipeline under explosion. KSCE J. Civil Eng. 21(7), 2798–2806 (2017)

Cheng, B.; Wang, H.B.; Zong, Q.: Numerical simulation on blasting mechanism of slotted cartridge based on coupled SPH-FEM algorithm. Chinese J. Energ. Mater. 28(4), 330–307 (2020)

Blair, D.P.: The free surface influence on blast vibration. Int. J. Rock Mech. Min. Sci. 77, 182–191 (2015)

Yang, J.H.; Cai, J.Y.; Yao, C.; Li, P.; Zhang, Q.H.; Zhou, C.B.: Comparative study of tunnel blast-induced vibration on tunnel surfaces and inside surrounding rock. Rock Mech. Rock Eng. 52(11), 4747–4761 (2019)

Cheng, B.; Wang, H.B.; Zong, Q.; Xu, Y.; Wang, M.X.; Zheng, Q.Q.; Li, C.J.: A study on cut blasting with large diameter charges in hard rock roadways. Adv. Civil Eng. 2020, 1–18 (2020)

Liu, K.; Li, Q.Y.; Wu, C.Q.; Li, X.B.; Li, J.: A study of cut blasting for one-step raise excavation based on numerical simulation and field blast tests. Int. J. Rock Mech. Mining Sci. 109, 91–104 (2018)

Yi, C.P.; Johansson, D.; Greberg, J.: Effects of in situ stresses on the fracturing of rock by blasting. Comput. Geotech. 104, 321–330 (2018)

Yuan, Y.; Yuan, C.F.; Zhu, C.; Liu, H.X.; Wang, S.Z.: Study on the disaster reduction mechanism of presplitting blasting and reasonable blasting parameters for shallowly buried remnant pillars. Energy Sci. Eng. 37(7), 2884–2894 (2019)

Yang, R.S.; Ding, C.X.; Yang, L.Y.; Lei, Z.; Zhen, C.D.: Study of decoupled charge blasting based on high-speed digital image correlation method. Tunnell. Underground Space Technol. 83, 51–59 (2019)

Li, H.B.; Xia, X.; Li, J.C.; Zhao, J.; Liu, B.; Liu, Y.Q.: Rock damage control in bedrock blasting excavation for a nuclear power plant. Int. J. Rock Mech. Min. Sci. 48, 210–218 (2011)

Li, X.P.; Huang, J.H.; Luo, Y.; Chen, P.P.: A study of smooth wall blasting fracture mechanisms using the timing sequence control method. Int. J. Rock Mech. Min. Sci. 92, 1–8 (2017)

Gong, F.Q.; Wang, J.; Li, X.B.: The rate effect of compression characteristics and a unified model of dynamic increasing factor for rock materials. Chinese J. Rock Mech. Eng. 37(7), 1586–1595 (2018)

Qiu, R.H.; Dong, Z.X.; Qi, Y.J.; Wang, Y.H.; Xie, L.D.; Liu, H.H.: Influence of seismic source parameters on the excitation wavelet in seismic explorations based on numerical simulation. Adv. Civil Eng. 2020, 1–9 (2020)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant no. 51404010), the Natural Science Research Project of Anhui Universities (Grant no. KJ2017ZD11), and the Patent Transformation Project of Anhui University of Science and Technology (Grant no. ZL201908).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, B., Wang, H., Zong, Q. et al. Study of the Double Wedge Cut Technique in Medium-Depth Hole Blasting of Rock Roadways. Arab J Sci Eng 46, 4895–4909 (2021). https://doi.org/10.1007/s13369-020-05279-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-05279-8