Abstract

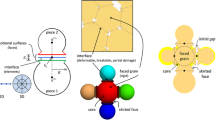

The internal microstructure of rock has an important influence on its macroscopic mechanical properties and fracture mechanism. In this paper, an equivalent crystal model (ECM) consisting of a bonded particle model and smooth joint model is established, which can simultaneously reflect the structure and content of mineral granules in rock. To verify the applicability and reliability of the ECM to further study the macroscopic nonlinear mechanical behaviour and fracture mechanism of rocks from a mesoscale perspective, this paper carried out numerical simulations of direct tension, uniaxial compression and triaxial compression loading using the particle flow code software, and the numerical results were compared with the test results of Beishan granite. The main research results are summarized as follows. (1) Under the condition of triaxial compression, with the increase in the confining pressure, the axial peak strain, radial peak strain, volume peak strain and post-peak residual strain of the rock all show an increasing trend. The rock exhibits an axial splitting failure mode dominated by tensile cracks and gradually changes to a shear failure mode dominated by shear cracks at an angle of approximately 45° from the loading direction. (2) Under direct tensile conditions, the failure of the rock manifests as cracks initiating from the middle of the specimen and extending approximately perpendicular to the tensile load direction, forming an approximately horizontal macroscopic crack composed of mineral granular boundaries. (3) The use of the ECM can reproduce a high ratio of the uniaxial compressive strength to the uniaxial tensile strength of the rock, and its strength characteristics show obvious nonlinear characteristics and meet the Hoek–Brown strength criterion. The rock strength and failure type obtained from the simulation are basically consistent with the test results, demonstrating the reliability of the ECM.

Similar content being viewed by others

References

Cundall, P.A.; Strack, O.D.L.: A discrete numerical model for granular assemblies. Geotechnique 29(1), 47–65 (1979)

Zhou, J.X.; Zhou, Y.; Gao, Y.T.: Effect mechanism of fractures on the mechanics characteristics of jointed rock mass under compression. Arab. J. Sci. Eng. 43(7), 3659–3671 (2018)

Wu, T.H.; Gao, Y.T.; Zhou, Y.; et al.: Experimental and numerical study on the interaction between holes and fissures in rock-like materials under uniaxial compression. Theor. Appl. Fract. Mech. 106 (2020)

Yoon, J.: Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation. Int. J. Rock Mech. Min. Sci. 44(6), 871–889 (2007)

Potyondy, D.O.; Cundall, P.A.: A bonded-particle model fo rrock. Int. J. Rock Mech. Min. Sci. 41(8), 1329–1364 (2004)

Li, J.W.; Zhou, Y.; Sun, W.; et al.: Effect of the interaction between cavity and flaw on the rock mechanical property under uniaxial compression. Adv. Mater. Sci. Eng. (2019), Article ID 1242141

Potyondy, D.O.: A flat-jointed bonded-particle material for rock. In: Proceedings of 52nd US Rock Mech/Geomech Symposium (Washington, USA, June 17–20, 2018), pp ARMA 18–1208 (2018)

Yoon, J.S.; Zang, A.; Stephansson, O.: Simulating fracture and friction of Aue granite under confined asymmetric compressive test using clumped particle model. Int. J. Rock Mech. Min. Sci. 49(1), 68–83 (2012)

Zhou, Y.; Wu, S.C.; Gao, Y.T.; et al.: Macro and meso analysis of jointed rock mass triaxial compression test by using ERM technique. J. Cent. South. Univ. T. 21(3), 1125–1135 (2014)

Zhou, Y.; Zhang, G.; Wu, S.C.; et al.: The effect of flaw on rock mechanical properties under the Brazilian test. Kuwait. J. Sci. 45(2), 94–103 (2018)

Guo, W.H.; Chen, N.B.; Zhou, Y.; et al.: Meso research on the mechanical properties of rock specimens with double prefabricated circular holes based on digital image correlation. Kuwait. J. Sci. 47(3), 2–14 (2020)

Park, J.W.; Song, J.J.: Numerical simulation of a direct shear test on a rock joint using a bonded-particle model. Int. J. Rock Mech. Min. Sci. 46(8), 1315–1328 (2009)

Zhang, S.H.; Wu, S.C.; Duan, K.: Study on the deformation and strength characteristics of hard rock under true triaxial stress state using bonded-particle model. Comput. Geotech. 112(8), 1–16 (2019)

Zhang, X.P.; Zhang, Q.; Wu, S.C.: Acoustic emission characteristics of the rock-like material containing a single flaw under different compressive loading rates. Comput. Geotech. 83, 83–97 (2017)

Ding, X.B.; Zhang, L.Y.: A new contact model to improve the simulated ratio of unconfined compressive strength to tensile strength inbonded particle models. Int. J. Rock Mech. Min. Sci. 69, 111–119 (2014)

Mehranpour, M.H.; Kulatilake, P.H.S.W.; Ma, X.; He, M.C.: Development of new three-dimensional rock mass strength criteria. Rock Mech. Rock Eng. 51, 1–25 (2018)

Zhou, Y.; Chen, N.B.; Wu, S.C.; et al.: A flat-joint contact model and meso analysis on mechanical characteristics of brittle rock. Kuwait. J. Sci. 46(3), 71–82 (2019)

Wu, S.C.; Xu, X.L.: A study of three intrinsic problems of the classic discrete element method using flat-joint model. Rock Mech. Rock Eng. 49(5), 1813–1830 (2016)

Xu, X.L.; Wu, S.C.; Gao, Y.T.; et al.: Effects of micro-structure and micro-parameters on Brazilian tensile strength using flat-joint model. Rock. Mech. Rock. Eng. (2016)

Yang, X.X.; Qiao, W.G.: Numerical investigation of the shear behavior of granite materials containing discontinuous joints by utilizing the flat-joint model. Comput. Geotech. 104(12), 69–80 (2018)

Cho, N.; Martin, C.D.; Sego, D.C.: A clumped particle model for rock. Int. J. Rock Mech. Min. Sci. 44(7), 997–1010 (2007)

Li, P.F.; Zhao, X.G.; Guo, Z.; et al.: Variation of strength parameters of Beishan granite under triaxial compression. Chin. J. Rock Mech. Eng. 36(7), 1599–1610 (2017)

Sun, X.; Li, E.B.; Duan, J.L.; et al.: Study on acoustic emission characteristics and damage evolution law of Beishangranite under triaxial compression. Chin. J. Rock Mech. Eng. 37(Suppl 2), 4234–4244 (2018)

Wang, C.L.; Li, E.B.; Han, Y.; et al.: Study on mechanical characteristics and fracture evolution of Beishan granite under triaxial compression. J. Forest. Eng. 3(4), 151–158 (2018)

Zhou, Y.; Gao, Y.T.; Wu, S.C.; et al.: An equivalent crystal model for mesoscopic behaviour of rock. Chin. J. Rock Mech. Eng. 34(3), 511–519 (2015)

Potyondy, D.O.: Smooth-Joint Model Version 2 (for PFC2D/3D Manual). Itasca Consulting Group, Minneapolis (2007)

Hoek, E.; Carranza-torres, C.T.; Corkum, B.: Hoek-Brown failure criterion-2002 edition. In: Proceedings of the Fifth North American Rock Mechanics Symposium. Toronto: [s.n.], pp. 267–273 (2002)

Acknowledgements

The work was supported by the Fundamental Research Funds for the Central Universities (Grant No. FRF-TP-18-016A3) and the National Natural Science Foundation of China (Grant No. 51504016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, W., Wang, L., Feng, S. et al. Mesoscopic Analysis of the Mechanical Properties of Beishan Granite Based on the Equivalent Crystal Model. Arab J Sci Eng 46, 4533–4542 (2021). https://doi.org/10.1007/s13369-020-05043-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-05043-y