Abstract

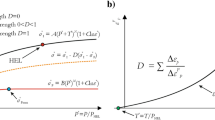

True 3D rock tests have revealed more complex (than axisymmetric conventional tests) constitutive behaviors of geomaterials which depend on the Lode angle and intermediate principal stress \(\sigma_{2}\). These tests, however, are subject to significant errors related to the end effects. It is important to understand which part of the stress–strain measurements is due to the actual rock properties, and which is caused by the end friction. We perform 3D finite-difference numerical simulations of true 3D tests approaching the real test conditions as closely as possible. Two constitutive models are used, one is the classical Mohr–Coulomb model, and the other is a recently developed 3-invariant 3ICM model calibrated with true 3D data for Castlegate sandstone. The results obtained with both models strongly depend on the end friction coefficient or friction angle \(\phi\) (notably along the \(\sigma_{2}\)-normal specimen faces), but the 3ICM model fits the data much better. At each constant \(\sigma_{3}\) and \(\phi > 0\), the measured (calculated) specimen model strength grows with \(\sigma_{2}\) increase, the growth rate being proportional to \(\phi\). The \(\phi\) increase also leads to an increase in the measured (apparent) stiffness. These results suggest that the experimentally defined typical arc-shaped curves \(\sigma_{1} (\sigma_{2}\)) at constant \(\sigma_{3}\) are progressively uplifted (with respect to real/intrinsic curves) when \(\sigma_{2}\) varies from \(\sigma_{3}\) to \(\sigma_{1}\).

Similar content being viewed by others

References

Mogi, K.: Fracture and flow of rocks under high triaxial compression. J. Geophys. Res. 76, 1255–1269 (1971)

Haimson, B.C.; Chang, C.: A new true triaxial cell for testing mechanical properties of rock, and its use to determine rock strength and deformability of Westerly granite. Int. J. Rock Mech. Min. Sci. 37, 285–296 (2000)

Haimson, B.C.: Consistent trends in the true triaxial strength and deformability of cores extracted from ICDP deep scientific holes on three continents. Tectonophysics 503, 45–51 (2011)

Sriapai, T.; Walsri, C.; Fuenkajorn, K.: True-triaxial compressive strength of Maha Sarakham salt. Int. J. Rock Mech. Min. Sci. 61, 256–265 (2013)

Ingraham, M.D.; Issen, K.A.; Holcomb, D.J.: Response of Castlegate sandstone to true triaxial states of stress. J. Geophys. Res. 118, 536–552 (2013)

Ma, X.D.; Haimson, B.C.: Failure characteristics of two porous sandstones subjected to true triaxial stresses. J. Geophys. Res. 121, 6477–6498 (2016)

Feng, X.T.; Zhang, X.W.; Kong, R.; Wang, G.: A novel Mogi type true triaxial testing apparatus and its use to obtain complete stress–strain curves of hard rocks. Rock Mech. Rock Eng. 49, 1649–1662 (2016)

Ma, X.D.; Rudnicki, J.W.; Haimson, B.C.: Failure characteristics of two porous sandstones subjected to true triaxial stresses: applied through a novel loading path. J. Geophys. Res. 122, 2525–2540 (2017)

Feng, X.T.; Kong, R.; Zhang, X.W.; Yang, C.X.: Experimental study of failure differences in hard rock under true triaxial compression. Rock Mech. Rock Eng. 52, 2109–2122 (2019)

Zhang, S.H.; Wu, S.C.; Zhang, G.: Strength and deformability of a low-porosity sandstone under true triaxial compression. Int. J. Rock Mech. Min. Sci. 127, 104204 (2020)

Du, K.; Yang, C.Z.; Su, R.; Tao, M.; Wang, S.F.: Failure properties of cubic granite, marble, and sandstone specimens under true triaxial stress. Int. J. Rock Mech. Min. Sci. 130, 104309 (2020)

Xu, Y.H.; Cai, M.; Zhang, X.W.; Feng, X.T.: Influence of end effect on rock strength in true triaxial compression test. Can. Geotech. J. 54, 862–880 (2017)

Willam, K.J.; Warnke, E.P.: Constitutive models for the triaxial behavior of concrete. IABSE Proc. 19, 1–30 (1975)

Van Eekelen, H.A.M.: Isotropic yield surfaces in three dimensions for use in soil mechanics. Int. J. Numer. Anal. Met. 4, 98–101 (1980)

Hsieh, S.S.; Ting, E.C.; Chen, W.F.: A plastic-fracture model for concrete. Int. J. Solids Struct. 18, 181–197 (1982)

Desai, C.S.; Salami, M.R.: A constitutive model and associated testing for soft rock. Int. J. Rock Mech. Min. Sci. 24, 299–307 (1987)

Lade, P.V.; Kim, M.K.: Single hardening constitutive model for frictional materials III: comparisons with experimental data. Comput. Geotech. 6, 31–47 (1988)

Li, M.H.; Yin, G.Z.; Xu, J.; Li, W.P.; Song, Z.L.; Jiang, C.B.: A novel true triaxial apparatus to study the geomechanical and fluid flow aspect of energy exploitations in geological formations. Rock Mech. Rock Eng. 49, 4647–4659 (2016)

Cai, M.: Influence of intermediate principal stress on rock fracturing and strength near excavation boundaries-insight from numerical modeling. Int. J. Rock Mech. Min. Sci. 45, 763–772 (2008)

Shi, L.; Li, X.C.: Analysis of end friction effect in true triaxial test. Rock Soil Mech. 30, 1159–1164 (2009)

Pan, P.Z.; Feng, X.T.; Hudson, J.A.: The influence of the intermediate principal stress on rock failure behavior: a numerical study. Eng. Geol. 124, 109–118 (2012)

Chemenda, A.I.; Mas, D.: Dependence of rock properties on the Lode angle: experimental data, constitutive model, and bifurcation analysis. J. Mech. Phys. Solids 96, 477–496 (2016)

Peng, S.D.: Stresses with inelastic circular cylinders loaded uniaxially and triaxially. Int. J. Rock Mech. Min. Sci. 8, 399–432 (1971)

Brady, B.T.: An exact solution to the radially end-constrained circular cylinder under triaxial loading. Int. J. Rock Mech. Min. Sci. 1971(8), 165–178 (1969)

Drescher, A.; Vardoulakis, I.: Geometric softening in triaxial tests on granular material. Géotechnique 32, 291–303 (1982)

Labuz, J.F.; Bridell, J.M.: Reducing frictional constraint in compression testing through lubrication. Int. J. Rock Mech. Min. Sci. 30, 451–455 (1993)

Pellegrino, A.; Sulem, J.; Barla, G.: The effects of slenderness and lubrication on the uniaxial behavior of a soft limestone. Int. J. Rock Mech. Min. Sci. 34, 333–340 (1997)

Albert, R.A.; Rudnicki, J.W.: Finite element simulations of Tennessee marble under plane strain laboratory testing: effects of specimen-platen friction on shear band onset. Mech. Mater. 33, 47–60 (2001)

Chemenda, A.I.: Three-dimensional numerical modeling of hydrostatic tests of porous rocks in a triaxial cell. Int. J. Rock Mech. Min. Sci. 76, 33–43 (2015)

Föppl, A.: Abhangigkeit der Bruchgefahr von der Art des Spannungszustandes. Mitth. Mech. Tech. Lab K. Tech. Hochsch München 27, 1–35 (1900)

Boyd, J.; Robertson, B.P.: The friction properties of various lubricants at high pressure. Trans. ASME 67, 51–59 (1945)

Allen, C.M.; Drauglis, E.: Boundary layer lubrication. Wear 14, 365–384 (1969)

Bowers, R.C.; Clinton, W.C.; Zisman, W.A.: Frictional behavior of polyethylene, polytetrafluoroethylene and halogenated derivatives. Lubr. Eng. 9, 204–219 (1953)

Wawersik, W.R.: Detailed Analysis of Rock Failure in Laboratory Compression Tests. University of Minnesota, Minnesota (1968)

Van Vliet, M.R.A.; Van Mier, J.G.M.: Experimental investigation of concrete fracture under uniaxial compression. Mech. Cohes-Frict. Mater. 1, 115–127 (1996)

Feng, X.T.; Zhang, X.W.; Yang, C.X.; Kong, R.; Liu, X.Y.; Peng, S.: Evaluation and reduction of the end friction effect in true triaxial tests on hard rocks. Int. J. Rock Mech. Min. Sci. 97, 144–148 (2017)

Niwa, Y.; Koyanagi, W.; Kobayashi, S.: Failure criterion of light weight concrete subjected to triaxial compression. Trans. Jpn. Soc. Civ. Eng. 147, 28–35 (1967)

Hawkes, I.; Mellor, M.: Uniaxial testing in rock mechanics laboratories. Eng. Geol. 4, 179–285 (1970)

Li, X.: Permeability Change in Sandstones Under Compressive Stress Conditions. Ibaraki University, Mito (2001)

Bowden, F.P.: Friction. Nature 166, 330–334 (1950)

Gaffney, E.: Measurements of dynamic friction between rock and steel. Defense Nuclear Agency (1976)

Liang, C.Y.; Zhang, Q.B.; Li, X.; Xin, P.: The effect of specimen shape and strain rate on uniaxial compressive behavior of rock material. B. Eng. Geol. Environ. 75, 1669–1681 (2015)

Bridell, J.M.: Reducing Frictional Constraint in Compression Testing Through Lubrication. University of Minnesota, Minnesota (1991)

Itasca Consulting Group: FLAC 3D (fast Lagrangian analysis of continua in 3-dimensions) 5.0 manual (2013)

Mas, D.; Chemenda, A.I.: An experimentally constrained constitutive model for geomaterials with simple friction–dilatancy relation in brittle to ductile domains. Int. J. Rock Mech. Min. Sci. 77, 257–264 (2015)

Mas, D.; Chemenda, A.I.: Dilatancy factor constrained from the experimental data for rocks and rock-type material. Int. J. Rock Mech. Min. Sci. 67, 136–144 (2014)

Fan, P.X.; Li, Y.; Zhao, Y.T.; Dong, L.; Ma, J.L.: End friction effect of Mogi type true-triaxial test apparatus. Chin. J. Rock Mech. Eng. 36, 2720–2730 (2017)

Xu, Y.H.; Cai M.: Numerical simulation of end constraint effect on post-peak behaviors of rocks in uniaxial compression. In: 49th US Rock Mechanics/Geomechanics Symposium. San Francisco, USA (2015)

Kumar, S.; Mukhopadhyay, T.; Waseem, S.A.; Singh, B.; Iqbal, M.A.: Effect of platen restraint on stress–strain behavior of concrete under axial compression: a comparative study. Strength Mater. 48, 592–602 (2016)

Acknowledgements

The first author thanks China Scholarship Council for the support to continue his PhD thesis in France and Julien Ambre for useful discussions and help.

Funding

This study was financially supported by the visiting scholor project funded by State Key Laboratory of Coal Mine Disaster Dynamics and Control (No. 2011DA105287-FW201901).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Chen, J., Chemenda, A.I. Numerical Simulation of True 3D Rock Tests with Classical and New Three-Invariant Constitutive Models Focusing on the End Effects. Arab J Sci Eng 45, 9367–9378 (2020). https://doi.org/10.1007/s13369-020-04750-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04750-w