Abstract

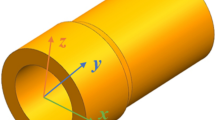

Pressure casting process, which is based on the principle of filling and solidifying the liquid metal into the mold cavity with the effect of speed and pressure, enables to obtain a serial product. The pressure casting process usually involves a thermal process. Starting with the casting process, the thermal resistances, especially formed at the casting mold interface, and the resultant interfacial heat transfer coefficient (IHTC) are among the most important factors determining the mechanical and physical properties of the produced part. The IHTC depends on the mold temperature, casting temperature, injection pressure, injection rate, vacuum application and many other incalculable parameters. In this study, it was aimed to determine the heat transfer coefficient and heat flux of the casting mold interface which has a significant effect on the quality of parts in the pressure casting of cylindrical mold geometry of AlSi8Cu3Fe aluminum alloy. The study was carried out depending on different casting temperatures, injection pressure, injection speed and vacuum application to the mold cavity. Temperatures were measured with thermocouples placed in the mold and casting material, IHTC and heat flux were calculated with finite difference method by using experimentally measured temperatures. In the application of artificial intelligence methods, casting temperature, injection speed, injection pressure and vacuum conditions are given as input parameters and interfacial flow coefficient and heat flux are accepted as output parameters. With the help of these parameters, DTR, MLR and ANNR deep learning algorithms were used to estimate the interfacial heat transfer coefficient. Among these algorithms, ANNR algorithm was found to be the most accurate estimating model at the rate of 99.9%. For the obtained model, a computer program was prepared for the users to be able to see and follow the experimental results and the results obtained from the model at the same time.

Similar content being viewed by others

References

Doehler, H.H.; Basınçlı Döküm, Ç.; Bayvas, M.Ş.: Mesleki ve Teknik Öğretim Kitapları, Etüd Ve Programlama Dairesi Yayınları No:80, Erkek Teknik Yüksek Öğretmen Okulu Matbaası, 514s, Ankara (1974)

Flemings, C.M.; Döküm Ve Katılaştırma, T.; Çeviren, B.M.: İstanbul Teknik Üniversitesi Matbaası, Gümüşsuyu, 415s, İstanbul (1976)

Vinarcık, J.E.: High Integrity Die Casting Processes. Wiley, New York (2003)

Anderesen, B.: Die Casting Engineering a Hydraulic, Thermal and Mechanical Process. Marcel Dekker, New York (2005)

Koru, M.: Basınçlı Döküm Yönteminde Al-Si (A413) Alaşımının Termal ve Dinamik Parametrelere Bağlı Olarak Ara Yüzey Isı Transfer Katsayısının Deneysel ve Teorik İncelenmesi. S.D.Ü. Fen Bilimleri Enstitüsü, Doktora Tezi, 157s., Isparta (2009)

İpek, O.; Koru, M.: Yüksek Basınçlı Döküm Prosesinde Kalıp Sıcaklığına Bağlı Olarak Döküm-Kalıp Ara Yüzeyinde Oluşan Termal Temas Direncinin Belirlenmesi. Isı Bilimi ve Tekniği Dergisi 31, 45–57 (2011)

Papai, J.P.: Contact heat transfer coefficient in aluminum alloy die casting: an experimental and numerical investigation. Ph.D. thesis, The Ohio State University (1994)

Assar, A.M.: Mould surface roughness and interfacial heat transfer using heat flow model. Mater. Sci. Technol. 13(8), 702 (1997)

Chen, Z.W.: Skin solidification during high pressure die casting of Al-11Si-2Cu-1Fe. Alloy Mater. Sci. Eng. 348, 145–153 (2003)

Dour, G.; Dargusch, M.; Davidson, C.: Recommendations and guidelines for the performance of accurate heat transfer measurements in rapid forming processes. Int. J. Heat Mass Transf. 49, 1773–1789 (2006)

Dour, G.; Dargusch, M.; Davidson, C.; Nef, A.: Development of a non-intrusive heat transfer coefficient gauge and its application to high pressure die casting effect of the process parameters. J. Mater. Process. Technol. 169, 223–233 (2005)

Şahin, H.M.; Kocatepe, K.; Kayıkçı, R.; Akar, N.: Ötektik Al-Si alaşımında soğutucu yüzey pürüzlülüğünün ara yüzey ısı transfer katsayısına etkisi. Gazi Üniv. Müh. Mim. Fak. Der. Cilt. 21(3), 473–481 (2006)

Akar, N.: Katılaşma sırasında döküm-Kalıp ara yüzeyinde ısı transfer katsayısının incelenmesi. Gazi Üniversitesi Fen Bilimleri Enstitüsü, Doktora Tezi, 136 S., Ankara (2006)

Griffiths, W.D.: Modelled heat transfer coefficient for al-7 wt-%si alloy casting unidirectionally solidified horizontally and vertically downwards. Mater. Sci. Technol. 16, 255–260 (2000)

Akar, N.; Şahin, H.M.; Yalçın, N.; Kocatepe, K.: Experimental study on the effect of liquid metal superheat and casting height on interfacial heat transfer coefficient. Exp. Heat Transf. 21, 83–98 (2008)

Akar, N.; Boran, K.; Hozikligil, B.: Effect of mold temperature on heat transfer coefficient at casting-mold interface. J. Fac. Eng. Archit. Gazi Univ. 28(2), 275–282 (2013)

Campbell, J.: Casting. Butterworth Heinemann, Oxford (2002)

Incropera, F.P.; Dewitt, D.P.: Fundamentals of Heat and Mass Transfer, 5th edn. Wiley, New York (2001)

Özışık, M.N.: Finite difference methods in heat transfer. Mechanical and Aerospace Engineering Department, North Carolina State University, p 412. CRC, Florida, USA (1994)

Lau, F.; Lee, W.B.; Xiong, S.M.; Liu, B.C.: A study of the interfacial heat transfer between an iron casting and a metallic mould. J. Mater. Process. Technol. 79, 25–29 (1998)

Zhi-peng, G.; Shou-mei, X.; Bai-cheng, L.; Li, M.; Allison, J.: Determination of the heat transfer coefficient at metal–die interface of high pressure die casting process of AM50 alloy. Int. J. Heat Mass Transf. 51(25), 6032–6038 (2008)

Hamasaiid, A.; Dour, G.; Dargusch, M.S.; Loulou, T.; Davidson, C.; Savage, G.: Heat-transfer coefficient and in-cavity pressure at the casting-die interface during high-pressure die casting of the magnesium alloy AZ91D. Metall. Mater. Trans. A 39a, 853 (2008)

Krimpenis, A.; Benardos, P.G.; Vosniakos, G.C.; Koukouvitaki, A.: Simulation-Based selection of optimum pressure die-casting process parameters using neural nets and genetic algorithms. Int. J. Adv. Manuf. Technol. 27, 509–517 (2006)

Loulou, T.; Artyukhin, E.A.; Bardon, J.P.: Estimation of thermal contact resistance during the first stage of metal solidification process: I-experiment principle and modelisation. Int. J. Heat Mass Transf. 42, 2119–2127 (1999)

Taha, M.A.; El-Mahallawy, N.A.; El-Mestekawi, M.T.; Hassan, A.A.: Estimation of air gap and heat transfer coefficient at different faces of Al and Al-Si casting solidifying in permanent mould. Mater. Sci. Technol. 17(9), 1093 (2001)

Santos, C.A.; Quaresma, J.M.V.; Garcia, A.: Determination of transient interfacial heat transfer coefficients in chill mold castings. J. Alloys Compd. 319, 174–186 (2001)

Gafur, M.A.; Haque, M.N.; Prabhu, K.N.: Effect of chill thickness and superheat on casting/chill interfacial heat transfer during solidification of commercially pure aluminum. J. Mater. Process. Technol. 133, 257–265 (2003)

Hallam, C.P.; Griffiths, W.D.: A model of the interfacial heat transfer coefficient for the aluminum gravity die casting process. Metall. Mater. Trans. 35(4), 721 (2004)

Srinivasan, M.N.: Heat transfer coefficients at the casting-mould interface during solidification of flake graphite cast iron in metallic mould. Indian J. Technol. 20(4), 123–129 (1982)

Broucaret, S.; Michrafy, A.; Dour, G.: Heat transfer and thermo-mechanical stresses in a gravity casting die influence of process parameters. J. Mater. Process. Technol. 110, 211–217 (2001)

Yaqoob, I.; Hashem, I.A.T.; Gani, A.; Mokhtar, S.; Ahmed, E.; Anuar, N.B.; Vasilakos, A.V.: Big data: from beginning to future. Int. J. Inf. Manag. 36(6), 1231–1247 (2016)

Zhang, D.: Big data security and privacy protection. In: 8th International Conference on Management and Computer Science (ICMCS 2018). Atlantis Press (2018)

Fan, S.K.S.; Su, C.J.; Nien, H.T.; Tsai, P.F.; Cheng, C.Y.: Using machine learning and big data approaches to predict travel time based on historical and real-time data from Taiwan electronic toll collection. Soft Comput. 22(17), 5707–5718 (2018)

Plageras, A.P.; Psannis, K.E.; Stergiou, C.; Wang, H.; Gupta, B.B.: Efficient IoT-based sensor BIG Data collection–processing and analysis in smart buildings. Future Gener. Comput. Syst. 82, 349–357 (2018)

Jing, X.; Yan, Z.; Pedrycz, W.: Security data collection and data analytics in the internet: a survey. IEEE Commun. Surv. Tutor. 21(1), 586–618 (2018)

Stieglitz, S.; Mirbabaie, M.; Ross, B.; Neuberger, C.: Social media analytics—challenges in topic discovery, data collection, and data preparation. Int. J. Inf. Manag. 39, 156–168 (2018)

Parmar, C.; Barry, J.D.; Hosny, A.; Quackenbush, J.; Aerts, H.J.: Data analysis strategies in medical imaging. Clin. Cancer Res. 24(15), 3492–3499 (2018)

Zhang, L.; Wang, H.; Li, Q.; Zhao, M.H.; Zhan, Q.M.: Big data and medical research in China. BMJ 360, j5910 (2018)

Lee, S.; Huh, J.H.: An effective security measures for nuclear power plant using big data analysis approach. J. Supercomput. 75, 1–28 (2018)

Mariani, M.; Baggio, R.; Fuchs, M.; Höepken, W.: Business intelligence and big data in hospitality and tourism: a systematic literature review. Int. J. Contemp. Hosp. Manag. 30(12), 3514–3554 (2018)

Ren, S.; Zhang, Y.; Liu, Y.; Sakao, T.; Huisingh, D.; Almeida, C.M.: A comprehensive review of big data analytics throughout product lifecycle to support sustainable smart manufacturing: a framework, challenges and future research directions. J. Clean. Prod. 210, 1343–1365 (2019)

Kuo, Y.H.; Kusiak, A.: From data to big data in production research: the past and future trends. Int. J. Prod. Res. 75, 1–26 (2018)

Russom, P.: Big data analytics. TDWI Best Pract. Rep. Fourth Quart. 19(4), 1–34 (2011)

Varatharajan, R.; Manogaran, G.; Priyan, M.K.: A big data classification approach using LDA with an enhanced SVM method for ECG signals in cloud computing. Multimed. Tools Appl. 77(8), 10195–10215 (2018)

Hamet, P.; Tremblay, J.: Artificial intelligence in medicine. Metab. Clin. Exp. 69, 36–40 (2017). https://doi.org/10.1016/j.metabol.2017.01.011

Lee, J.; Davari, H.; Singh, J.; Pandhare, V.: Industrial artificial intelligence for industry 4.0-based manufacturing systems. Manuf. Lett. 18, 20–23 (2018)

Li, B.; Chai, X.; Hou, B.; Zhang, L.; Zhou, J.; Liu, Y.: New generation artificial intelligence-driven intelligent manufacturing (NGAIIM). In: 2018 IEEE SmartWorld, Ubiquitous Intelligence & Computing, Advanced & Trusted Computing, Scalable Computing & Communications, Cloud & Big Data Computing, Internet of People and Smart City Innovation (SmartWorld/SCALCOM/UIC/ATC/CBDCom/IOP/SCI), pp. 1864–1869. IEEE (2018)

Roll, I.; Wylie, R.: Evolution and revolution in artificial intelligence in education. Int. J. Artif. Intell. Educ. 26(2), 582–599 (2016)

Spronck, P.; André, E.; Cook, M.; Preuß, M.: Artificial and computational intelligence in games: AI-driven game design (Dagstuhl Seminar 17471). In: Dagstuhl Reports, vol. 7, no. 11. Schloss Dagstuhl-Leibniz-Zentrum fuer Informatik (2018)

Fok, S.C.; Ong, E.K.: A high school project on artificial intelligence in robotics. Artif. Intell. Eng. 10(1), 61–70 (1996). https://doi.org/10.1016/0954-1810(95)00016-X

Taşar, B.; Üneş, F.; Demirci, M.; Kaya, Y.Z.: Yapay sinir ağları yöntemi kullanılarak buharlaşma miktarı tahmini. DÜMF Mühendislik Dergisi 9(1), 543–551 (2018)

Haykin, S.: Neural Networks: A Comprehensive Foundation. Prentice Hall PTR, Upper Saddle River (1994)

Zhu, A.X.: Artificial neural networks. Int. Encycl. Geogr. People Earth Environ. Technol. People Earth Environ. Technol. 15, 1–6 (2016)

Turkson, R.F.; Yan, F.; Ali, M.K.A.; Hu, J.: Artificial neural network applications in the calibration of spark-ignition engines: an overview. Eng. Sci. Technol. Int. J. 19(3), 1346–1359 (2016)

Ata, R.: Artificial neural networks applications in wind energy systems: a review. Renew. Sustain. Energy Rev. 49, 534–562 (2015)

Guresen, E.; Kayakutlu, G.; Daim, T.U.: Using artificial neural network models in stock market index prediction. Expert Syst. Appl. 38(8), 10389–10397 (2011)

Mba, L.; Meukam, P.; Kemajou, A.: Application of artificial neural network for predicting hourly indoor air temperature and relative humidity in modern building in humid region. Energy Build. 121, 32–42 (2016)

Murugan, S.; Kumar, B.M.; Amudha, S.:. Classification and prediction of breast cancer using linear regression, decision tree and random forest. In: 2017 International Conference on Current Trends in Computer, Electrical, Electronics and Communication (CTCEEC), pp. 763–766. IEEE (2017)

Ignatov, D.; Ignatov, A.: Decision stream: cultivating deep decision trees. In: 2017 IEEE 29th International Conference on Tools with Artificial Intelligence (ICTAI), pp. 905–912. IEEE (2017)

Electronic Statistics Textbook, in Tulsa, StatSoft, OK, USA (2013)

Swetapadma, A.; Yadav, A.: A novel decision tree regression-based fault distance estimation scheme for transmission lines. IEEE Trans. Power Deliv. 32(1), 234–245 (2016)

Quraishi, M.Z.; Mouazen, A.M.: Development of a methodology for in situ assessment of topsoil dry bulk density. Soil Tillage Res. 126, 229–237 (2013)

Choubin, B.; Khalighi-Sigaroodi, S.; Malekian, A.; Kişi, Ö.: Multiple linear regression, multi-layer perceptron network and adaptive neuro-fuzzy inference system for forecasting precipitation based on large-scale climate signals. Hydrol. Sci. J. 61(6), 1001–1009 (2016)

Gardner, M.W.; Dorling, S.R.: Artificial neural networks (the multilayer perceptron)—a review of applications in the atmospheric sciences. Atmos. Environ. 32(14–15), 2627–2636 (1998)

Kaneko, H.: Beware of r2 even for test datasets: using the latest measured y-values (r2LM) in time series data analysis. J. Chemom. 33(2), e3093 (2019)

Susac, F.; Teodor, V.G.; Ganea, D.: Estimation of Heat Transfer Coefficient in Permanent Mold Casting Using Artificial Neural Networks, New Technologies and Products in Machine Manufacturing Technologies (2017)

Vishweshwara, P.S.; Gnanasekaran, N.; Arun, M.: Inverse approach using bio-inspired algorithm within Bayesian framework for the estimation of heat transfer coefficients during solidification of casting. J. Heat Transf. 142(1), 012403 (2020)

Vishweshwara, P.S.; Gnanasekaran, N.; Arun, M.: Simultaneous estimation of unknown parameters using a priori knowledge for the estimation of interfacial heat transfer coefficient during solidification of Sn–5wt% Pb alloy—an ANN-driven Bayesian approach. Sādhanā 44(4), 100 (2019)

Rajaraman, R.; Velraj, R.: Comparison of interfacial heat transfer coefficient estimated by two different techniques during solidification of cylindrical aluminum alloy casting. Heat Mass Transf. 44(9), 1025–1034 (2008)

Rao, R.V.; Kalyankar, V.D.; Waghmare, G.: Parameters optimization of selected casting processes using teaching–learning-based optimization algorithm. Appl. Math. Model. 38(23), 5592–5608 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aksoy, B., Koru, M. Estimation of Casting Mold Interfacial Heat Transfer Coefficient in Pressure Die Casting Process by Artificial Intelligence Methods. Arab J Sci Eng 45, 8969–8980 (2020). https://doi.org/10.1007/s13369-020-04648-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04648-7