Abstract

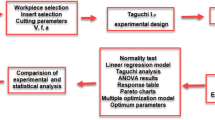

In this study, hard turning tests are carried out on the hardened AISI 4140 steel material. Power consumption, sound intensity, processing time and surface roughness values are measured for all combinations of cutting conditions such as three different cutting speeds, three different feed rates, three different depths of cut and two different tool cutting edge angle. According to these measurements, the ideal cutting condition is found by using the TOPSIS method which is integrated by fuzzy Hamming distance, Euclidean distance and Hausdorff distance measure methods. Also in case that machinability parameters have different importance degrees, ideal cutting condition is determined by using the weighted fuzzy distance measure method. According to the experimental results obtained, it is observed that the surface roughness value increased with the increasing feed rate. Roughness values obtained at 90 degree tool cutting edge angle are lower than 62.5 degrees. It is observed that the sound intensity increases with the increasing feed rate. The machining time is reduced with increasing feed rate, depth of cut and cutting speed. Thus, total power consumption is reduced.

Similar content being viewed by others

References

Chaudhari, R.G.; Hashimoto, F.: Process controls for surface integrity generated by hard turning. Procedia CIRP 45, 15–18 (2016)

Chaudhari, R.; Hashimoto, F.: A novel work holding method for hard turning using the shoe-centerless concept. CIRP Ann. 67(1), 113–116 (2018)

Matsumoto, Y.; Hashimoto, F.; Lahoti, G.: Surface integrity generated by precision hard turning. CIRP Ann. 48(1), 59–62 (1999)

Poulachon, G.; Moisan, A.; Jawahir, I.S.: On modelling the influence of thermo-mechanical behavior in chip formation during hard turning of 100Cr6 bearing steel. CIRP Ann. 50(1), 31–36 (2001)

Tönshoff, H.K.; Arendt, C.; Ben Amor, R.: Cutting of hardened steel. CIRP Ann. 49(2), 547–566 (2000)

Kumar, ChS; Patel, S.K.: Application of surface modification techniques during hard turning: present work and future prospects. Int. J. Refract. Met. Hard Mater. 76, 112–127 (2018)

Khan, S.A.; Umar, M.; Saleem, M.Q.; Mufti, N.A.; Raza, S.F.: Experimental investigations on wiper inserts’ edge preparation, workpiece hardness and operating parameters in hard turning of AISI D2 steel. J. Manufact. Process. 34(A), 187–196 (2018)

Uhlman, E.; Riemer, H.; Schröter, D.; Henze, S.; Sammler, F.; Barthelma, F.; Frank, H.: Investigation of wear resistance of coated PcBN turning tools for hard machining. Int. J. Refract. Met. Hard Mater. 72, 270–275 (2018)

Liev, P.J.; Shaaroni, A.; Sidik, N.A.C.; Yan, J.: An overview of current status of cutting fluids and cooling techniques of turning hard steel. Int. J. Heat Mass Transf. 114, 380–384 (2017)

Aggarwal, A.; Singh, H.; Kumar, P.; Singh, M.: Optimizing power consumption for CNC turned parts using response surface methodology and Taguchi’s technique-A comparative analysis. J. Mater. Process. Technol. 200, 373–384 (2008)

Aouici, H.; Yallese, M.A., Chaoui, K.; Mabrouki ve J. Rigal, T.: Analysis of surface roughness and cutting force components in hard turning with CBN tool: prediction model and cutting conditions optimization. Measurement 45, 344–353 (2012)

Bouacha, K.; Yallese, M.A.; Mabrouki Ve, T.; Rigal, J.: Statistical analysis of surface roughness and cutting forces using response surface methodology in hard turning of AISI 52100 bearing steel with CBN tool. Int. J. Refract. Met. Hard Mater. 28, 349–361 (2010)

Hessainia, Z.; Belbah, A.; Yallese, M.A.; Mabrouki Ve, T.; Rigal, J.F.: On the prediction of surface roughness in the hard turning based on cutting parameters and tool vibrations. Measurement 46, 1671–1681 (2013)

Moganapriya, C.; Rajasekar, R.; Ponappa, K.; Venkatesh Ve, R.; Jerome, S.: Influence of coating material and cutting parameters on surface roughness and material removal rate in turning process using taguchi method. Mater. Today Proc. 5, 8532–8538 (2018)

Mia, M.; Dey, P.R.; Hossain, M.S.; Arafat, Md.T.; Asaduzzaman, Md., Ullah, Md.S.; Zobaer, S.M.T.: Taguchi S/N based optimization of machining parameters for surface roughness, tool wear and material removal rate in hard turning under MQL cutting condition. Measurement 122, 380–391 (2018)

Siraj, S.; Darmad Hikari, H.M.; Gore, N.: Modeling of roughness value from tribological parameters in hard turning of AISI 52100 Steel. Proc. Manuf. 20, 344–349 (2018)

Yang, J.; Wang, X.; Kang, M.: Finite element simulation of surface roughness in diamond turning of spherical surfaces. J. Manufact. Process. 31, 768–775 (2018)

Bhushan, R.K.: Optimization of cutting parameters for minimizing power consumption and maximizing tool life during machining of Al alloy SiC particle composites. J. Clean. Product. 39, 242–254 (2013)

Kant ve, G.; Sangwan, K.: Prediction and optimization of machining parameters for minimizing power consumption and surface roughness in machining. J. Clean. Product. 83, 151–164 (2014)

Bilga, P.S.; Singh Ve, S.; Kumar, R.: Optimization of energy consumption response parameters for turning operation using Taguchi method. J. Clean. Product. 137, 1406–1417 (2016)

Bagaber ve, S.A.; Yusoff, A.R.: Multi-objective optimization of cutting parameters to minimize power consumption in dry turning of stainless steel 316. J. Clean. Product. 157, 30–46 (2017)

Ş. Karabulut ve A. Şahinoğlu: Effect of the cutting parameters on surface roughness, power consumption and machine noise in machining of R260 steel. Politeknik Dergisi 21(1), 237–244 (2018)

Lv, J.; Tang, R.; Tang, W.; Jia, S.; Liu, Y.; Cao, Y.: An investigation into methods for predicting material removal energy consumption in turning. J. Clean. Product. 193, 128–139 (2018)

Hu, L.; Liu, W.; Xu, K.; Peng, T.; Yang, H.; Tang, R.: Turning part design for joint optimisation of machining and transportation energy consumption. J. Clean. Product. 232, 67–78 (2019)

Kumar, R.; Bilga, P.S.; Singh, S.: Multi objective optimization using different methods of assigning weights to energy consumption responses, surface roughness and material removal rate during rough turning operation. J. Clean. Product. 164, 45–57 (2017)

Mikaeil, R.; Yousefi, R.; Ataei, M.: Sawability ranking of carbonate rock using fuzzy analytical hierarchy process and TOPSIS approaches. Scientia Iranica 18(5), 1106–1115 (2011)

Bashiri, M.; Geranmayeh, A.F.: Tuning the parameters of an artificial neural network using central composite design and genetic algorithm. Scientia Iranica 18(6), 1600–1608 (2011)

Yue, Z.: Application of the projection method to determine weights of decision makers for group decision making. Scientia Iranica 19(3), 872–878 (2012)

Poorzadehy, H.; Rezaei, A.: Peer evaluation of multi-attribute analysis techniques: Case of a light rail transit network choice. Scientia Iranica 20(3), 371–386 (2013)

Rao, R.V.; Kalyankar, V.D.: Multi-pass turning process parameter optimization using teaching-learning-based optimization algorithm. Scientia Iranica 20(3), 967–974 (2013)

Yoon, K.; Hwang, C.L.: Multiple Attribute Decision Making: Methods and Applications. Springer, Berlin (1981)

Hung, C.C.; Chen L.H.: A fuzzy TOPSIS decision making model with entropy weight under intuitionistic fuzzy environment. In: Proceedings of the International Multi-Conference of Engineers and Computer Scientists IMECS, Hong Kong (2009)

Zadeh, L.A.: Fuzzy sets. Inf. Control 8, 338–353 (1965)

Chen, G.; Pham, T.T.: Introduction to Fuzzy Sets, Fuzzy Logic, and Fuzzy Control Systems. CRC Press, Boca Raton (2000)

Bojadziev, G.; Bojadziev, M.: Fuzzy Sets, Fuzzy Logic, Applications, Advances in Fuzzy Systems — Applications and Theory, vol. 5. World Scientific, Singapore (1995)

Kacprzyk, J.: Multistage Fuzzy Control. Wiley, Chichester (1997)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.

Rights and permissions

About this article

Cite this article

Karaaslan, F., Şahinoğlu, A. Determination of Ideal Cutting Conditions for Maximum Surface Quality and Minimum Power Consumption During Hard Turning of AISI 4140 Steel Using TOPSIS Method Based on Fuzzy Distance. Arab J Sci Eng 45, 9145–9157 (2020). https://doi.org/10.1007/s13369-020-04635-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04635-y