Abstract

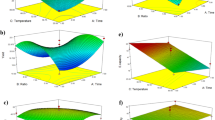

Papaya seed waste can be a reliable feedstock for producing valuable bioproducts (biodiesel, biolubricants, beauty products, etc.) due to its high oil content. This article focuses to explore the effects of Soxhlet extraction process conditions (extraction time and seed particle size) on the percent oil yield obtained from papaya seeds. Initially, two mathematical models were developed using response surface methodology (RSM) via central composite design and regression analysis (generalized linear model, GLM) to predict the oil yield. The prediction performance of RSM model was found to be superior than GLM. The extracted oil was characterized by gas chromatography–mass spectrometry (GC–MS) analysis. The analysis of variance results indicated that both factors were strongly significant. Later, crow search algorithm (nature-motivated metaheuristic algorithm) articulated with RSM was utilized for global optimal solution. The maximum yield of 29.96% was obtained at extraction time of 6.5 h and seed particle size of 0.85 mm. The similar results were obtained by desirability function-based optimization approach. The predicted optimal set was also validated further by experimental yield of 31.1% with the variation of < 5%.

Similar content being viewed by others

Abbreviations

- OFAT:

-

One-factor-at-a-time

- RSM:

-

Response surface methodology

- CCD:

-

Central composite design

- BBD:

-

Box–Behnken design

- GLM:

-

Generalized linear model

- A :

-

Extraction time (T)

- B :

-

Seed particle size (S)

- ANOVA:

-

Analysis of variance

- y :

-

Predicted response

- CSA:

-

Crow search algorithm

- AP:

-

Awareness probability

- fl:

-

Flight length

- N:

-

Flock size

- GC–MS:

-

Gas chromatography–mass spectrometry

- RE:

-

Relative error

- MAE:

-

Mean absolute error

- RMSE:

-

Root mean squared error

- DF:

-

Desirability function

References

Abas, N.; Kalair, A.; Khan, N.: Review of fossil fuels and future energy technologies. Futures 69, 31–49 (2015)

Miller, R.G.; Sorrell, S.R.: The future of oil supply. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. (2014). https://doi.org/10.1098/rsta.2013.0179

Ganjehkaviri, A.; Mohd Jaafar, M.N.; Hosseini, S.E.; Musthafa, A.B.: Performance evaluation of palm oil-based biodiesel combustion in an oil burner. Energies 9, 1–10 (2016). https://doi.org/10.3390/en9020097

Mosarof, M.H.; Kalam, M.A.; Masjuki, H.H.; Alabdulkarem, A.; Habibullah, M.; Arslan, A.; Monirul, I.M.: Assessment of friction and wear characteristics of Calophyllum inophyllum and palm biodiesel. Ind. Crops Prod. 83, 470–483 (2016). https://doi.org/10.1016/J.INDCROP.2015.12.082

Mosarof, M.H.; Kalam, M.A.; Masjuki, H.H.; Alabdulkarem, A.; Ashraful, A.M.; Arslan, A.; Rashedul, H.K.; Monirul, I.M.: Optimization of performance, emission, friction and wear characteristics of palm and Calophyllum inophyllum biodiesel blends. Energy Convers. Manag. 118, 119–134 (2016). https://doi.org/10.1016/J.ENCONMAN.2016.03.081

Parthiban, K.S.; Perumalsamy, M.: Kinetic studies on oil extraction and biodiesel production from underutilized Annona squamosa seeds. Fuel 180, 211–217 (2016). https://doi.org/10.1016/j.fuel.2016.04.020

Mathiarasi, R.; Partha, N.: Optimization, kinetics and thermodynamic studies on oil extraction from Daturametel Linn oil seed for biodiesel production. Renew. Energy 96, 583–590 (2016). https://doi.org/10.1016/j.renene.2016.04.078

Anwar, M.; Rasul, M.G.; Ashwath, N.: The synergistic effects of oxygenated additives on papaya biodiesel binary and ternary blends. Fuel 256, 115980 (2019). https://doi.org/10.1016/j.fuel.2019.115980

Anwar, M.; Rasul, M.G.; Ashwath, N.; Nabi, M.D.N.: The potential of utilising papaya seed oil and stone fruit kernel oil as non-edible feedstock for biodiesel production in Australia—a review. Energy Rep. 5, 280–297 (2019). https://doi.org/10.1016/j.egyr.2019.02.007

Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Fattah, I.M.R.; Mobarak, H.M.: Comparative evaluation of performance and emission characteristics of Moringa oleifera and Palm oil based biodiesel in a diesel engine. Ind. Crops Prod. 53, 78–84 (2014). https://doi.org/10.1016/j.indcrop.2013.12.011

Ighose, B.O.; Adeleke, I.A.; Damos, M.; Junaid, H.A.; Okpalaeke, K.E.; Betiku, E.: Optimization of biodiesel production from Thevetia peruviana seed oil by adaptiveneuro-fuzzyinferencesystem coupledwithgeneticalgorithmandresponse surface methodology. Energy Convers. Manag. 132, 231–240 (2017)

Nayak, M.G.; Vyas, A.P.: Optimization of microwave-assisted biodiesel production from Papaya oil using response surface methodology. Renew. Energy 138, 18–28 (2019). https://doi.org/10.1016/J.RENENE.2019.01.054

Anwar, M.; Rasul, M.G.; Ashwath, N.: Production optimization and quality assessment of papaya (Carica papaya) biodiesel with response surface methodology. Energy Convers. Manag. 156, 103–112 (2018). https://doi.org/10.1016/J.ENCONMAN.2017.11.004

Sandouqa, A.; Al-Hamamre, Z.: Energy analysis of biodiesel production from jojoba seed oil. Renew. Energy 130, 831–842 (2019). https://doi.org/10.1016/j.renene.2018.07.015

Fernandes, K.V.; Papadaki, A.; da Silva, J.A.C.; Fernandez-Lafuente, R.; Koutinas, A.A.; Freire, D.M.G.: Enzymatic esterification of palm fatty-acid distillate for the production of polyol esters with biolubricant properties. Ind. Crops Prod. 116, 90–96 (2018). https://doi.org/10.1016/j.indcrop.2018.02.058

Malacrida, C.R.; Kimura, M.; Jorge, N.: Characterization of a high oleic oil extracted from papaya (Carica papaya L.) seeds. Ciência e Tecnol. Aliment. 31, 929–934 (2012). https://doi.org/10.1590/s0101-20612011000400016

Barroso, P.T.W.; de Carvalho, P.P.; Rocha, T.B.; Pessoa, F.L.P.; Azevedo, D.A.; Mendes, M.F.: Evaluation of the composition of Carica papaya L. seed oil extracted with supercritical CO2. Biotechnol. Rep. 11, 110–116 (2016). https://doi.org/10.1016/J.BTRE.2016.08.004

Sharma, S.K., Mitra, S.K., Saran, S.: Papaya production in India—History, present status and future prospects. In: Acta Horticulturae, pp. 87–94. International Society for Horticultural Science (2016)

Puangsri, T.; Abdulkarim, S.M.; Ghazali, H.M.: Properties of Carica papaya L. (papaya) seed oil following extraction using solvent and aqueous enzymatic methods. J. Food Lipids. 12, 62–76 (2005). https://doi.org/10.1111/j.1745-4522.2005.00006.x

Singh, G.; Pai, R.S.; Devi, V.K.: Response surface methodology and process optimization of sustained release pellets using Taguchi orthogonal array design and central composite design. J. Adv. Pharm. Technol. Res. 3, 30–41 (2012). https://doi.org/10.4103/2231-4040.93565

Daryono, E.D.; Sinaga, E.J.: Rapid in situ transesterification of papaya seeds to biodiesel with the aid of co-solvent. J. Renew. Energy Res. 7, 379–385 (2017)

Chan, H.T.; Heu, R.A.; Tang, C.S.; Okazaki, E.N.; Ishizaki, S.M.: Composition of papaya seeds. J. Food Sci. 43, 255–261 (1978)

Kiralan, M.; Özkan, G.; Bayrak, A.; Ramadan, M.F.: Physicochemical properties and stability of black cumin (Nigella sativa) seed oil as affected by different extraction methods. Ind. Crops Prod. 57, 52–58 (2014). https://doi.org/10.1016/j.indcrop.2014.03.026

Soto, C.; Chamy, R.; Zúñiga, M.E.: Enzymatic hydrolysis and pressing conditions effect on borage oil extraction by cold pressing. Food Chem. 102, 834–840 (2007). https://doi.org/10.1016/j.foodchem.2006.06.014

Mohammed, N.K.; AbdManap, M.Y.; Tan, C.P.; Muhialdin, B.J.; Alhelli, A.M.; Hussin, A.S.M.: The effects of different extraction methods on antioxidant properties, chemical composition, and thermal behavior of black seed (Nigella sativa L.) oil. Evidence-based complement. Altern. Med. (2016). https://doi.org/10.1155/2016/6273817

Zhang, S.; Zu, Y.-G.; Fu, Y.-J.; Luo, M.; Liu, W.; Li, J.; Efferth, T.: Supercritical carbon dioxide extraction of seed oil from yellow horn (Xanthoceras sorbifolia Bunge.) and its anti-oxidant activity. Bioresour. Technol. 101, 2537–2544 (2009). https://doi.org/10.1016/j.biortech.2009.11.082

Shah, S.; Sharma, A.; Gupta, M.N.: Extraction of oil from Jatropha curcas L. seed kernels by combination of ultrasonication and aqueous enzymatic oil extraction. Bioresour. Technol. 96, 121–123 (2005). https://doi.org/10.1016/j.biortech.2004.02.026

Suryawanshi, B.; Mohanty, B.: Application of an artificial neural network model for the supercritical fluid extraction of seed oil from Argemone mexicana (L.) seeds. Ind. Crops Prod. 123, 64–74 (2018). https://doi.org/10.1016/j.indcrop.2018.06.057

Devi, V.; Khanam, S.: Development of generalized and simplified models for supercritical fluid extraction: case study of papaya (Carica papaya) seed oil. Chem. Eng. Res. Des. 150, 341–358 (2019). https://doi.org/10.1016/J.CHERD.2019.08.006

Ajiwe, V.I.E.; Umerie, S.C.; Okeke, C.A.; Oburota, V.N.: Extraction and utilisation of cassava seed oil. Bioresour. Technol. 47, 85–86 (1994). https://doi.org/10.1016/0960-8524(94)90033-7

Okieimen, F.E.; Eromosele, C.O.: Fatty acid composition of the seed oil of Khaya senegalensis. Bioresour. Technol. 69, 279–280 (1999). https://doi.org/10.1016/S0960-8524(98)00190-4

Sarin, R.; Sharma, M.; Khan, A.A.: Terminalia belerica Roxb seed oil: a potential biodiesel resource. Bioresour. Technol. 101, 1380–1384 (2010). https://doi.org/10.1016/j.biortech.2009.09.018

Ajiwe, V.I.E.; Okeke, C.A.; Agbo, H.U.: Extraction and utilization of breadfruit seed oil (Treculia africana). Bioresour. Technol. 53, 183–184 (1995). https://doi.org/10.1016/0960-8524(95)00059-N

Samaram, S.; Mirhosseini, H.; Tan, C.P.; Ghazali, H.M.: Ultrasound-assisted extraction and solvent extraction of papaya seed oil: crystallization and thermal behavior, saturation degree, color and oxidative stability. Ind. Crops Prod. 52, 702–708 (2014). https://doi.org/10.1016/j.indcrop.2013.11.047

Samaram, S.; Mirhosseini, H.; Tan, C.P.; Ghazali, H.M.; Bordbar, S.; Serjouie, A.: Optimisation of ultrasound-assisted extraction of oil from papaya seed by response surface methodology: oil recovery, radical scavenging antioxidant activity, and oxidation stability. Food Chem. 172, 7–17 (2015). https://doi.org/10.1016/J.FOODCHEM.2014.08.068

Venter, G.: Review of optimization techniques. In: Blockley, R. (ed.) Encyclopedia of Aerospace Engineering. Wiley, Chichester (2010)

Nuchitprasittichai, A.; Cremaschi, S.: Optimization of CO2 capture process with aqueous amines using response surface methodology. Comput. Chem. Eng. 35, 1521–1531 (2011). https://doi.org/10.1016/J.COMPCHEMENG.2011.03.016

Bhran, A.A.; Shoaib, A.M.; Umana, B.: Optimization of crude oil hydrotreating process as a function of operating conditions: application of response surface methodology. Comput. Chem. Eng. 89, 158–165 (2016). https://doi.org/10.1016/J.COMPCHEMENG.2016.03.026

Aniceto, J.P.S.; Cardoso, S.P.; Silva, C.M.: General optimization strategy of simulated moving bed units through design of experiments and response surface methodologies. Comput. Chem. Eng. 90, 161–170 (2016). https://doi.org/10.1016/J.COMPCHEMENG.2016.04.028

Vargas, E.M.; Ospina, J.L.; Tarelho, L.A.C.; Nunes, M.I.: FAME production from residual materials: optimization of the process by Box–Behnken model. Energy Reports. 6, 347–352 (2020). https://doi.org/10.1016/j.egyr.2019.08.071

Holland, D.G.: Genetic Algorithms in Search, Optimization and Machine Learning. Addison-Wesley, Boston (1989)

Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P.: Optimization by simulated annealing (80-). Science 220, 671–680 (1983). https://doi.org/10.1126/science.220.4598.671

Rabbouch, B.; Saâdaoui, F.; Mraihi, R.: Empirical-type simulated annealing for solving the capacitated vehicle routing problem. J. Exp. Theor. Artif. Intell. (2019). https://doi.org/10.1080/0952813X.2019.1652356

DORIGO, M.: Optimization, Learning and Natural Algorithms. Ph.D. Thesis, Politec, di Milano (1992)

Kennedy, J., Eberhart, R.: Particle swarm optimization. In: Proceedings of the IEEE International Joint Conference on Neural Network,. pp. 1942–1948 (1995)

Rabbouch, B.; Mraihi, R.; Saâdaoui, F.: A recent brief survey for the multi depot heterogenous vehicle routing problem with time windows. In: Abraham, A., Muhuri, P., Muda, A., Gandhi, N. (eds.) Advances in Intelligent Systems and Computing, vol. 734, pp. 147–157. Springer, Cham (2018)

Geem, Z.W.; Kim, J.H.; Loganathan, G.V.: A new heuristic optimization algorithm: harmony search. Simulation. 76, 60–68 (2001). https://doi.org/10.1177/003754970107600201

Askarzadeh, A.: A novel metaheuristic method for solving constrained engineering optimization problems: crow search algorithm. Comput. Struct. 169, 1–12 (2016). https://doi.org/10.1016/j.compstruc.2016.03.001

Samantha, B.S.; Trupthi, M.; Sairam, U.: A review on using crow search algorithm in solving the problems of constrained optimization. Int. J. Sci. Res. Sci. Tech. 4, 1374–1387 (2018)

Javidi, A.; Salajegheh, E.; Salajegheh, J.: Enhanced crow search algorithm for optimum design of structures. Appl. Soft Comput. J. 77, 274–289 (2019). https://doi.org/10.1016/j.asoc.2019.01.026

Gupta, D.; Sundaram, S.; Khanna, A.; Ella Hassanien, A.; de Albuquerque, V.H.C.: Improved diagnosis of Parkinson’s disease using optimized crow search algorithm. Comput. Electr. Eng. 68, 412–424 (2018). https://doi.org/10.1016/j.compeleceng.2018.04.014

Horng, S.C.; Lin, S.S.: Merging crow search into ordinal optimization for solving equality constrained simulation optimization problems. J. Comput. Sci. 23, 44–57 (2017). https://doi.org/10.1016/j.jocs.2017.10.001

Nobahari, H., Bighashdel, A.: MOCSA: A multi-objective crow search algorithm for multi-objective optimization. In: 2017 2nd Conference on Swarm Intelligence and Evolutionary Computation (CSIEC), pp. 60–65. IEEE (2017)

Tamilarasan, A., Renugambal, A., Manikanta, D., Sekhar Reddy, G.B.C., Sravankumar, K., Sreekar, B., Prasadreddy, G. V.: Application of crow search algorithm for the optimization of abrasive water jet cutting process parameters. In: IOP Conferernce on Series Material Science Engineering, vol. 390, (2018). https://doi.org/10.1088/1757-899X/390/1/012034

Sayed, G.I., Darwish, A., Hassanien, A.E.: Chaotic crow search algorithm for engineering and constrained problems. In: 2017 12th International Conference on Computer Engineering and Systems (ICCES), pp. 676–681. IEEE (2017)

Ela, A.A.A. El, El-Sehiemy, R.A., Shaheen, A.M., Shalaby, A.S.: Application of the crow search algorithm for economic environmental dispatch. In: 2017 Nineteenth International Middle East Power Systems Conference (MEPCON), pp. 78–83. IEEE (2017)

Zaki, D.A., Hasanien, H.M., El-Amary, N.H., Abdelaziz, A.Y.: Crow search algorithm for improving the performance of an inverter-based distributed generation system. In: 2017 Nineteenth International Middle East Power Systems Conference (MEPCON), pp. 656–663. IEEE (2017)

Kumar, U.A.: Comparison of neural networks and regression analysis: a new insight. Expert Syst. Appl. 29, 424–430 (2005). https://doi.org/10.1016/j.eswa.2005.04.034

Myers, R.H.; Montgomery, D.C.; Vining, G.G.; Robinson, T.J.: Generalized Linear Models: with Applications in Engineering and the Sciences, 2nd edn. Wiley, New York (2010)

Moradi, M.; Arabi, H.; Shamsborhan, M.: Multi-objective optimization of high power diode laser surface hardening process of AISI 410 by means of RSM and desirability approach. Optik (Stuttg) (2019). https://doi.org/10.1016/j.ijleo.2019.163619

Palanikumar, K.; Muthukrishnan, N.; Hariprasad, K.S.: Surface roughness parameters optimization in machining A356/SiC/20p metal matrix composites by PCD tool using response surface methodology and desirability function. Mach. Sci. Technol. 12, 529–545 (2008). https://doi.org/10.1080/10910340802518850

Chabbi, A.; Yallese, M.A.; Meddour, I.; Nouioua, M.; Mabrouki, T.; Girardin, F.: Predictive modeling and multi-response optimization of technological parameters in turning of Polyoxymethylene polymer (POM C) using RSM and desirability function. Meas. J. Int. Meas. Confed. 95, 99–115 (2017). https://doi.org/10.1016/j.measurement.2016.09.043

Montgomery, D.C.; Runger, G.C.: Applied Statistics and probability for engineers. John Wiley & Sons, Ltd (2002)

Montgomery, D.C.: Design and Analysis of Experiments. Wiley, New York (2001)

Box, G.E.P.; Hunter, W.G.; Hunter, J.S.: Statistics for Experimenters. Wiley, New York (1978)

Aslan, N.; Cebeci, Y.: Application of Box–Behnken design and response surface methodology for modeling of some Turkish coals. Fuel 86, 90–97 (2007). https://doi.org/10.1016/j.fuel.2006.06.010

Hajslova, J.; Cajka, T.: Gas chromatography–mass spectrometry (GC–MS). In: Yolanda, P. (ed.) Food Toxicants Analysis, pp. 419–473. Elsevier, Amsterdam (2007)

Hunter, E.A.; Haaland, P.D.: Experimental Design in Biotechnology. Biometrics 47, 348 (2006). https://doi.org/10.2307/2532528

Cicero, A.F.G.; Nascetti, S.; López-Sabater, M.C.; Elosua, R.; Salonen, J.T.; Nyyssönen, K.; Poulsen, H.E.; Zunft, H.-J.F.; Kiesewetter, H.; de la Torre, K.; Covas, M.-I.; Kaikkonen, J.; Mursu, J.; Koenbick, C.; Bäumler, H.; Gaddi, A.V.: EUROLIVE Study Group: changes in LDL fatty acid composition as a response to olive oil treatment are inversely related to lipid oxidative damage: The EUROLIVE study. J. Am. Coll. Nutr. 27, 314–320 (2008)

Acknowledgements

Authors would like to gratefully acknowledge the support provided by King Abdulaziz City for Science and Technology (KACST) through the Science and Technology Unit at King Fahd University of Petroleum and Minerals (KFUPM) for funding this work through Project No. NSTIP # 13-WAT096-04 as part of the National Science, Technology and Innovation Plan. S. M. Zakir Hossain would also like to thank the Deanship of Scientific Research (Grant #: 10/2014), University of Bahrain, Kingdom of Bahrain.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplemental Figure S1

GC-MS analysis of the fatty acid composition of total lipids extracted from papaya seeds (TIFF 48 kb)

Rights and permissions

About this article

Cite this article

Hossain, S.M.Z., Taher, S., Khan, A. et al. Experimental Study and Modeling Approach of Response Surface Methodology Coupled with Crow Search Algorithm for Optimizing the Extraction Conditions of Papaya Seed Waste Oil. Arab J Sci Eng 45, 7371–7383 (2020). https://doi.org/10.1007/s13369-020-04551-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04551-1