Abstract

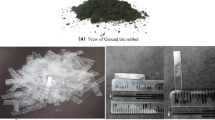

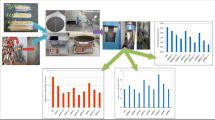

The influences of fibres originating from different waste materials on the fresh and hardened properties of self-compacting concrete (SCC) were investigated in this study. For this purpose, a total number of 13 mixes of wood (WF), polyvinyl chloride (PF), aluminium (AF), and iron filing (IF) fibres, with volume fractions (Vf) of 0.5%, 1.0%, and 1.5% were prepared. The investigated fresh properties of the prepared mixes were slump flow, T500, V-funnel as well as L-box tests, while the hardened properties were compressive strength, flexural strength, and ultrasonic pulse velocity (UPV). The findings indicated that although the majority of the prepared SCC mixes met the required self-compacting criteria, the inclusion of the waste fibres negatively affected the mix workability, particularly when Vf of 1.5% was used. Regarding the hardened properties, SCC mixes-containing IF exhibited a slight increase in both compressive and flexural strength compared with the reference mix without fibres, whereas mixes with AF fibres demonstrated a noticeable decrease in compressive strength, but with a comparable level of flexural strength. However, the flexural strength of WF and PF decreased as their Vf increased in the SCC mixes, although a slight increase in compressive strength was noted in the mixes with PF. Furthermore, there was no reliable relationship to be constructed between the compressive strength and UPV tests for all fibres used.

Similar content being viewed by others

References

Shi, C.; Wu, Z.; Lv, K.; Wu, L.: A review on mixture design methods for self-compacting concrete. Constr. Build. Mater. 84, 387–398 (2015)

Siad, H.; Mesbah, H.A.; Mouli, M.; Escadeillas, G.; Khelafi, H.: Influence of mineral admixtures on the permeation properties of self-compacting concrete at different ages. Arab. J. Sci. Eng. 39(5), 3641–3649 (2014)

Beygi, M.H.; Kazemi, M.T.; Nikbin, I.M.; Amiri, J.V.; Rabbanifar, S.; Rahmani, E.: The influence of coarse aggregate size and volume on the fracture behavior and brittleness of self-compacting concrete. Cem. Concr. Res. 66, 75–90 (2014)

Deeb, R.; Ghanbari, A.; Karihaloo, B.L.: Development of self-compacting high and ultra high performance concretes with and without steel fibres. Cement Concr. Compos. 34(2), 185–190 (2012)

Karihaloo, B.L.; Ghanbari, A.: Mix proportioning of self-compacting high-and ultra-high-performance concretes with and without steel fibres. Mag. Concr. Res. 64(12), 1089–1100 (2012)

El-Dieb, A.; Taha, M.R.: Flow characteristics and acceptance criteria of fiber-reinforced self-compacted concrete (FR-SCC). Constr. Build. Mater. 27(1), 585–596 (2012)

Grünewald, S.; Walraven, J.C.: Parameter-study on the influence of steel fibers and coarse aggregate content on the fresh properties of self-compacting concrete. Cem. Concr. Res. 31(12), 1793–1798 (2001)

Sahmaran, M.; Yurtseven, A.; Yaman, I.O.: Workability of hybrid fiber reinforced self-compacting concrete. Build. Environ. 40(12), 1672–1677 (2005)

Thomas, J.; Ramaswamy, A.: Mechanical properties of steel fiber-reinforced concrete. J. Mater. Civ. Eng. 19(5), 385–392 (2007)

Nguyen, T.; Toumi, A.; Turatsinze, A.: Mechanical properties of steel fibre reinforced and rubberised cement-based mortars. Mater. Des. 31(1), 641–647 (2010)

Wang, K.; Young, B.; Smith, S.T.: Mechanical properties of pultruded carbon fibre-reinforced polymer (CFRP) plates at elevated temperatures. Eng. Struct. 33(7), 2154–2161 (2011)

Yakhlaf, M.; Safiuddin, M.; Soudki, K.: Properties of freshly mixed carbon fibre reinforced self-consolidating concrete. Constr. Build. Mater. 46, 224–231 (2013)

Behnood, A.; Verian, K.P.; Gharehveran, M.M.: Evaluation of the splitting tensile strength in plain and steel fiber-reinforced concrete based on the compressive strength. Constr. Build. Mater. 98, 519–529 (2015)

Matar, P.; Assaad, J.J.: Concurrent effects of recycled aggregates and polypropylene fibers on workability and key strength properties of self-consolidating concrete. Constr. Build. Mater. 199, 492–500 (2019)

As’ad, S.; Gunawan, P.; Alaydrus, M.S.: Fresh state behavior of self compacting concrete containing waste material fibres. Procedia Eng. 14, 97–804 (2011)

Al-Hadithi, A.I.; Hilal, N.N.: The possibility of enhancing some properties of self-compacting concrete by adding waste plastic fibers. J. Build. Eng. 8, 20–28 (2016)

Ghernouti, Y.; Rabehi, B.; Bouziani, T.; Ghezraoui, H.; Makhloufi, A.: Fresh and hardened properties of self-compacting concrete containing plastic bag waste fibers (WFSCC). Constr. Build. Mater. 82, 89–100 (2015)

Mastali, M.; Dalvand, A.; Sattarifard, A.: The impact resistance and mechanical properties of reinforced self-compacting concrete with recycled glass fibre reinforced polymers. J. Clean. Prod. 124, 312–324 (2016)

ASTMC150/C150M-15: Standard Specification for Portland Cement ASTM International, West Conshohocken, PA, Doi: 10.1520/C0150–15. (2015)

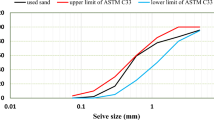

ASTMC136M-14: Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates; West Conshohocken, PA, USA. (2014)

ASTMC494–13: Standard Specification for Chemical Admixtures for Concrete. Book of ASTM Standards, vol. 4 (2013)

Yazıcı, Ş.; İnan, G.; Tabak, V.: Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Constr. Build. Mater. 21(6), 1250–1253 (2007)

544, A.C.: Guide for Specifying, Proportioning, Mixing, Placing, and Finishing Steel Fiber Reinforced Concrete. American Concrete Institute (1998)

Pierre, P.; Pleau, R.; Pigeon, M.: Mechanical properties of steel microfiber reinforced cement pastes and mortars. J. Mater. Civ. Eng. 11(4), 317–324 (1999)

Abo, D.M.; Al-Rubaye, M.; Alyhya, W.; Karihaloo, B.; Kulasegaram, S.: Proportioning of self–compacting concrete mixes based on target plastic viscosity and compressive strength: part I-mix design procedure. J. Sustain. Cem. Based Mater. 5(4), 199–216 (2016)

Abo, D.M.S.; Al-Rubaye, M.M.; Alyhya, W.S.; Karihaloo, B.L.; Kulasegaram, S.: Proportioning of self-compacting concrete mixes based on target plastic viscosity and compressive strength: Part II-experimental validation. J. Sustain. Cem. Based Mater. 5(4), 217–232 (2016)

EFNARC: The European Guidelines for Self-Compacting Concrete: Specification, Production and Use, The Self-Compacting Concrete European Project Group. (2005).

Assaad, J.J.: Influence of recycled aggregates on dynamic/static stability of self-consolidating concrete. J. Sustain. Cem. Based Mater. 6(6), 345–365 (2017)

Tviksta, L.-G.R.: Task 9 End Product, Guidelines. Swedish Cement and Concrete Research Institute, p. 48. (2000)

British:Standard: BS 1881: Part 116:. Method for Determination of Compressive Strength of Concrete Cubes. (1983)

ASTMC293–02: Standard test method for flexural strength of concrete (Using sample beam with center-point loading). Annual book of ASTM standards, American Society for Testing and Materials (2003)

Khaloo, A.; Raisi, E.M.; Hosseini, P.; Tahsiri, H.: Mechanical performance of self-compacting concrete reinforced with steel fibers. Constr. Build. Mater. 51, 179–186 (2014)

Hesami, S.; Hikouei, I.S.; Emadi, S.A.A.: Mechanical behavior of self-compacting concrete pavements incorporating recycled tire rubber crumb and reinforced with polypropylene fiber. J. Clean. Prod. 133, 228–234 (2016)

Ahmad, S.; Umar, A.: Rheological and Mechanical properties of Self-Compacting Concrete with Glass and Polyvinyl Alcohol Fibres. J. Build. Eng. 17, 65–74 (2018)

Borhan, T.M.; Janna, H.: Thermal properties of cement mortar containing waste aluminium fine aggregate. J. Karbala Univ. 14(2), 193–200 (2016)

Araújo, E. G. D.; Tenório, J. A. S.: Cellular concrete with addition of aluminum recycled foil powders. In: Materials Science Forum. Trans Tech Publ (2005)

Meddah, M.S.; Bencheikh, M.: Properties of concrete reinforced with different kinds of industrial waste fibre materials. Constr. Build. Mater. 23(10), 3196–3205 (2009)

Domone, P.: Self-compacting concrete: An analysis of 11 years of case studies. Cement Concr. Compos. 28(2), 197–208 (2006)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Borhan, T.M., Abo Dhaheer, M.S. & Mahdi, Z.A. Characteristics of Sustainable Self-compacting Concrete Reinforced by Fibres from Waste Materials. Arab J Sci Eng 45, 4359–4367 (2020). https://doi.org/10.1007/s13369-020-04460-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04460-3