Abstract

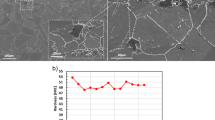

Inconel 718 is a nickel-based superalloy extensively used in aerospace industries for its excellent physical, mechanical and chemical properties. Poor thermal conductivity, high toughness and strong work hardening tendency of this alloy adversely affect its machinability. Inconel 718 is therefore treated as ‘difficult to cut’ or ‘hard to cut’. Conventional machining of Inconel 718 faces various challenges like high cutting forces, evolution of huge cutting temperature and rapid tool wear. As a consequence, surface integrity of the machined part becomes disappointing. Excessive tool wear incurs additional cost of tool replacement. To overcome machining difficulties of this alloy, application of coated tool insert is recommended. To this end, the present work attempts to investigate machining performance of Inconel 718 using coated carbide (cemented carbide) tool with chemical vapour deposition multi-layer coating TiN/TiCN/Al2O3/TiN (TN4000) under dry cutting environment. Turning experiments are conducted with varied cutting speeds: 50, 75, 100 and 125 m/min at constant feed rate 0.1 mm/rev and constant depth of cut 0.4 mm. Chip morphology including features of chip cross section, free surface of chip and chip reduction coefficient as affected by cutting speed is studied herein. Abrasion, adhesion, chipping off, coating delamination, built-up edge formation, diffusion, etc. are identified as potential wear mechanisms. In addition to flank wear and crater wear, occurrence of notch wear is also distinctly identified. Surface roughness of the finished work part is found better in case of coated tool than uncoated one. Coated tool corresponds to lesser cutting force magnitude, lower cutting temperature and higher value of chip reduction coefficient than the case of traditional uncoated tool.

Similar content being viewed by others

References

Rahman, M.; Seah, W.K.H.; Teo, T.T.: The machinability of Inconel 718. J. Mater. Process. Technol. 63(1–3), 199–204 (1997)

Arunachalam, R.M.; Mannan, M.A.; Spowage, A.C.: Surface integrity when machining age hardened Inconel 718 with coated carbide cutting tools. Int. J. Mach. Tools Manuf. 44(14), 1481–1491 (2004)

Sharman, A.; Dewes, R.C.; Aspinwall, D.K.: Tool life when high speed ball nose end milling Inconel 718. J. Mater. Process. Technol. 118(1–3), 29–35 (2001)

Ezugwu, E.O.; Wang, Z.M.; Machado, A.R.: The machinability of nickel-based alloys: a review. J. Mater. Process. Technol. 86(1–3), 1–16 (1999)

Jawaid, A.; Koksal, S.; Sharif, S.: Cutting performance and wear characteristics of PVD coated and uncoated carbide tools in face milling Inconel 718 aerospace alloy. J. Mater. Process. Technol. 116(1), 2–9 (2001)

Li, L.; He, N.; Wang, M.; Wang, Z.W.: High speed cutting of Inconel 718 with coated carbide and ceramic inserts. J. Mater. Process. Technol. 129(1–3), 127–130 (2002)

Kitagawa, T.; Kubo, A.; Maekawa, K.: Temperature and wear of cutting tools in high speed machining of Inconel and Ti–6Al–6V–2Sn. Wear 202(2), 142–148 (1997)

Arunachalam, R.; Mannan, M.A.: Machinability of nickel-based high temperature alloys. Mach. Sci. Technol. 4(1), 127–168 (2000)

Devillez, A.; Schneider, F.; Dominiak, S.; Dudzinski, D.; Larrouquere, D.: Cutting forces and wear in dry machining of Inconel 718 with coated carbide tools. Wear 262(7–8), 931–942 (2007)

Nalbant, M.; Altin, A.; Gokkaya, H.: The effect of cutting speed and cutting tool geometry on machinability properties of nickel-base Inconel 718 super alloys. Mater. Des. 28(4), 1334–1338 (2007)

Dhar, N.R.; Islam, M.W.; Islam, S.; Mithu, M.A.H.: The influence of minimum quantity of lubrication (MQL) on cutting temperature, chip and dimensional accuracy in turning AISI-1040 steel. J. Mater. Process. Technol. 171(1), 93–99 (2006)

Dudzinski, D.; Devillez, A.; Moufki, A.; Larrouquère, D.; Zerrouki, V.; Vigneau, J.: A review of developments towards dry and high speed machining of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 44(4), 439–456 (2004)

Lux, B.; Columbier, C.; Atena, H.; Stemberg, K.: Preparation of alumina coatings by chemical vapor deposition. Thin Solid Films 138(1), 49–64 (1986)

Prengel, H.G.; Pfouts, W.R.; Santhanam, A.T.: State of the art in hard coatings for carbide cutting tools. Surf. Coat. Technol. 102(3), 183–190 (1998)

Choudhury, I.A.; El-Baradie, M.A.: Machining nickel base superalloys: Inconel 718. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 212(3), 195–206 (1998)

Kishawy, H.A.; Elbestawi, M.A.: Effects of process parameters on material side flow during hard turning. Int. J. Mach. Tools Manuf. 39(7), 1017–1030 (1999)

Sharman, A.R.C.; Hughes, J.I.; Ridgway, K.: An analysis of the residual stresses generated in Inconel 718™ when turning. J. Mater. Process. Technol. 173(3), 359–367 (2006)

Bhatt, A.; Attia, H.; Vargas, R.; Thomson, V.: Wear mechanisms of WC coated and uncoated tools in finish turning of Inconel 718. Tribol. Int. 43(5–6), 1113–1121 (2010)

Ibrahim, G.A.; Haron, C.H.C.; Ghani, J.A.; Said, A.Y.M.; Yazid, M.Z.A.: Performance of PVD-coated carbide tools when turning Inconel 718 in dry machining. Adv. Mech. Eng. 2011, 1–7 (2011). https://doi.org/10.1155/2011/790975

Obikawa, T.; Yamaguchi, M.: Suppression of notch wear of a whisker reinforced ceramic tool in air-jet-assisted high-speed machining of Inconel 718. Precis. Eng. 39, 143–151 (2015)

Hao, Z.P.; Fan, Y.H.; Lin, J.Q.; Yu, Z.X.: Wear characteristics and wear control method of PVD-coated carbide tool in turning Inconel 718. Int. J. Adv. Manuf. Technol. 78(5–8), 1329–1336 (2015)

Zhang, B.; Njora, M.J.; Sato, Y.: High-speed turning of Inconel 718 by using TiAlN- and (Al, Ti) N-coated carbide tools. Int. J. Adv. Manuf. Technol. 96(5–8), 2141–2147 (2018)

Abbasi, S.A.; Pingfa, F.: Evaluating the effectiveness of various coating layers applied on k-grade cemented carbide cutting tools on machinability of titanium alloy Ti–6Al–4V in high speed end milling. In: 2015 12th International Bhurban Conference on Applied Sciences and Technology (IBCAST). IEEE, pp. 14–19 (2015)

Jawahir, I.S.; van Luttervelt, C.A.: Recent developments in chip control research and applications. CIRP Ann. Manuf. Technol. 42(2), 659–693 (1993)

Hou, Z.B.; Komanduri, R.: Modeling of thermomechanical shear instability in machining. Int. J. Mech. Sci. 39(11), 1273–1314 (1997)

Pawade, R.S.; Joshi, S.S.; Brahmankar, P.K.; Rahman, M.: An investigation of cutting forces and surface damage in high-speed turning of Inconel 718. J. Mater. Process. Technol. 192, 139–146 (2007)

Shokrani, A.; Dhokia, V.; Newman, S.T.: Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int. J. Mach. Tools Manuf. 57, 83–101 (2012)

Liao, Y.S.; Lin, H.M.; Wang, J.H.: Behaviors of end milling Inconel 718 superalloy by cemented carbide tools. J. Mater. Process. Technol. 201(1–3), 460–465 (2008)

Pawade, R.S.; Joshi, S.S.: Mechanism of chip formation in high-speed turning of Inconel 718. Mach. Sci. Technol. 15(1), 132–152 (2011)

Thakur, A.; Gangopadhyay, S.: Evaluation of micro-features of chips of Inconel 825 during dry turning with uncoated and chemical vapour deposition multilayer coated tools. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 232(6), 979–994 (2018)

Upadhyay, V.; Jain, P.K.; Mehta, N.K.: Comprehensive study of chip morphology in turning of Ti–6Al–4V. In: 5th International and 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) December 12th–14th, 2014, IIT Guwahati, Assam, India (2014)

Dong, G.; Zhaopeng, H.; Rongdi, H.; Yanli, C.; Muguthu, J.N.: Study of cutting deformation in machining nickel-based alloy Inconel 718. Int. J. Mach. Tools Manuf. 51(6), 520–527 (2011)

Wang, C.; Xie, Y.; Zheng, L.; Qin, Z.; Tang, D.; Song, Y.: Research on the chip formation mechanism during the high-speed milling of hardened steel. Int. J. Mach. Tools Manuf. 79, 31–48 (2014)

Koyilada, B.; Gangopadhyay, S.; Thakur, A.: Comparative evaluation of machinability characteristics of Nimonic C-263 using CVD and PVD coated tools. Measurement 85, 152–163 (2016)

Joshi, S.; Tewari, A.; Joshi, S.: Influence of preheating on chip segmentation and microstructure in orthogonal machining of Ti6Al4V. J. Manuf. Sci. Eng. 135(6), 061017 (2013)

Li, H.Z.; Zeng, H.; Chen, X.Q.: An experimental study of tool wear and cutting force variation in the end milling of Inconel 718 with coated carbide inserts. J. Mater. Process. Technol. 180(1–3), 296–304 (2006)

Liao, Y.S.; Shiue, R.H.: Carbide tool wear mechanism in turning of Inconel 718 superalloy. Wear 193(1), 16–24 (1996)

Cantero, J.L.; Díaz-Álvarez, J.; Miguélez, M.H.; Marín, N.C.: Analysis of tool wear patterns in finishing turning of Inconel 718. Wear 297(1–2), 885–894 (2013)

Akhtar, W.; Sun, J.; Sun, P.; Chen, W.; Saleem, Z.: Tool wear mechanisms in the machining of nickel based super-alloys: a review. Front. Mech. Eng. 9(2), 106–119 (2014)

Zhuang, K.; Zhu, D.; Zhang, X.; Ding, H.: Notch wear prediction model in turning of Inconel 718 with ceramic tools considering the influence of work hardened layer. Wear 313(1–2), 63–74 (2014)

Ghani, J.A.; Haron, C.H.C.; Kasim, M.S.; Sulaiman, M.A.; Tomadi, S.H.: Wear mechanism of coated and uncoated carbide cutting tool in machining process. J. Mater. Res. 31(13), 1873–1879 (2016)

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

S | N | M | G | 12 | 0.4 | 0.8 |

|---|---|---|---|---|---|---|

Insert shape | End clearance angle | Tolerance class | Insert features | Size (D) | Thickness (S) | Corner radius (Rc) |

Square − 90° | Zero | ± 0.13 on thickness ± 0.002 to ± .010 on diameter | Chip breaker on both the sides | 12.70 mm | 4.76 | 0.80 mm |

Appendix 2

Representation of chip–tool contact length

Rights and permissions

About this article

Cite this article

Rakesh, M., Datta, S. Machining of Inconel 718 Using Coated WC Tool: Effects of Cutting Speed on Chip Morphology and Mechanisms of Tool Wear. Arab J Sci Eng 45, 797–816 (2020). https://doi.org/10.1007/s13369-019-04171-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-04171-4