Abstract

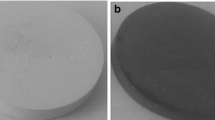

Clays are most important raw materials in the development of ceramic products, especially ceramic tiles body formulation. Optimization of properties of local clays for application in ceramic tiles industry is important to minimize production costs. The aim of this research work is to optimize properties of ceramic tile bodies containing three Malaysian clays (from Ipoh, Kuala Rompin and Mersing) effectively by using design of mixture experiment of both common floor (pressed at 20 MPa and sintered at 1105 °C) and porcelain (pressed at 31 MPa and sintered at 1170 °C) tiles production practices. Fired properties of body formulation were analysed by fired shrinkage in diameter and thickness, water absorption, bulk density, fired colour of L* and coefficient of thermal expansion. The outcome of the research work indicates that studied clays are suitable to be used in producing almost all ranges of ceramic tiles, but their application is highly dependent on the mineralogical composition and production parameters, such as pressing pressure and sintering temperature.

Similar content being viewed by others

References

José, M.M.; Jacinto, A.A.: What is clay? A new definition of “clay” based on plasticity and its impact on the most widespread soil classification systems. Appl. Clay Sci. 161, 57–63 (2018)

Pardo, F.; Jordan, M.M.; Montero, M.A.: Ceramic behaviour of clays in Central Chile. Appl. Clay Sci. 157, 158–164 (2018)

Ngun, B.K.; Mohamad, H.; Sulaiman, S.K.; Okada, K.; Ahmad, Z.A.: Some ceramic properties of clays from central Cambodia. Appl. Clay Sci. 53, 33–41 (2011)

Aripin, H.; Mitsudo, S.; Rahmat, B.; Tani, S.; Sako, K.; Fujii, Y.; Kikuchi, K.; Saito, T.; Idehara, T.; Sabchevski, S.: Formation of porous clay ceramic using sago waste ash as a prospective additive material with controllable milling. Sci. Sinter. 46, 55–64 (2014)

Bennour, A.; Mahmoudi, S.; Srasra, E.; Boussen, S.; Htira, N.: Composition, firing behaviour and ceramic properties of the Sejnène clays (Northwest Tunisia). Appl. Clay Sci. 115, 30–38 (2015)

Tutić, E.; Jovanović, M.; Mujkanović, A.: Preparation of mullite ceramics from bayer electrofilter fines and low kaolinite clay. Sci. Sinter. 48, 247–257 (2016)

Ismail, S.; Kasim, Z.C.; Harun, H.C.: Malaysia Minerals Year Book 2010, pp. 74–87. Minerals and Geoscience Department of Malaysia, Ministry of Natural Resources and Environment Malaysia, Putrajaya (2010)

Chin, C.L.; Ahmad, Z.A.; Sow, S.S.: Relationship between the thermal behavior of the clays and their mineralogical and chemical composition: example of Ipoh, Kuala Rompin and Mersing (Malaysia). Appl. Clay Sci. 115, 327–335 (2017)

Correia, S.L.; Hotza, D.; Segadães, A.M.: Simultaneous optimization of linear firing shrinkage and water absorption of triaxial ceramic bodies using experiments design. Ceram. Int. 30, 917–922 (2004)

Ngun, B.K.; Mohamad, H.; Katsumata, K.; Okada, K.; Ahmad, Z.A.: Using design of mixture experiments to optimize triaxial ceramic tile compositions incorporating Cambodian clays. Appl. Clay Sci. 87, 97–107 (2014)

Coronado, M.; Segadães, A.M.; Andrés, A.: Combining mixture design of experiments with phase diagrams in the evaluation of structural ceramics containing foundry by-products. Appl. Clay Sci. 101, 390–400 (2014)

Cornell, J.A.: Experiments with Mixtures: Designs, Models and the Analysis of Mixture Data, 3rd edn. Wiley, New York (2002)

Menezes, R.R.; Neto, H.G.M.; Santana, L.N.L.; Lira, H.L.: Optimization of wastes content in ceramics tiles using statistical design of mixture experiments. J. Eur. Ceram. Soc. 28, 3027–3039 (2008)

Oliveira, H.A.; Silva, D.C.; Oliveira, R.M.P.B.; Santos, C.P.; de Jesus, E.; Macedo, Z.S.: Estimating isotherm parameters of drying clay for the ceramic industry of Sergipe, Brazil. Appl. Clay Sci. 161, 211–214 (2018)

Ferrari, S.; Gualtieri, A.F.: The use of illitic clays in the production of stoneware tile ceramics. Appl. Clay Sci. 32, 73–81 (2006)

Guzmán, A.A.; Gordillo, S.M.; Delvasto, A.S.; Quereda, V.M.F.; Sánchez, V.E.: Optimization of the technological properties of porcelain tile bodies containing rice straw ash using the design of experiments methodology. Ceram. Int. 42(14), 15383–15396 (2016)

Ryan, W.: Properties of Ceramic Raw Materials, 2nd edn. Pergamon Press, New York (1978)

Bryman, A.; Cramer, D.: Quantitative Data Analysis with Minitab—A Guide for Social Scientists. Routledge, New York (1996)

Ott, R.L.; Longnecker, M.: An Introduction to Statistical Methods and Data Analysis, 5th edn. Duxbury, Belmont (2001)

Marcelo, D.B.; Adriano, M.B.; Dachamir, H.: Formulation of ceramic engobes with recycled glass using mixture design. J. Clean. Prod. 69, 243–249 (2014)

Santos, L.R.D.; Melchiades, F.G.; Nastri, S.; Boschi, A.O.: Fluxing agents for porcelain tiles produced by the dry route. In: Qualicer, pp. 1–11 (2012)

Dondi, M.; Raimondo, M.; Zanelli, C.: Clays and bodies for ceramic tiles: reappraisal and technological classification. Appl. Clay Sci. 96, 91–109 (2014)

ISO 13006: Ceramic Tiles—Definitions, Classification, Characteristics and Marking, 1st Edn. International Standard (2012)

Correia, S.L.; Oliveira, A.P.N.; Hotza, D.; Segadães, A.M.: Properties of triaxial porcelain bodies: interpretation of statistical modelling. J. Am. Ceram. Soc. 89, 3356–3365 (2006)

Furlani, E.; Maschio, S.: Mechanical properties and microstructure of fast fired tiles made with blends of kaolin and olivine powders. Ceram. Int. 39, 9391–9396 (2013)

Hassan, M.H.; Al-Marzouki Jeffrey, C.; Khater, G.A.: Evaluation of Saudi pegmatite and its use in porcelain industry. Process. Appl. Ceram. 6(3), 133–140 (2012)

Gámiz, E.; Melgosa, M.; Sánchez-Marañón, M.; Martín-García, J.M.; Delgado, R.: Relationships between chemico-mineralogical composition and color properties in selected natural and calcined Spanish kaolins. Appl. Clay Sci. 28, 269–282 (2005)

Chin, C.L.; Ahmad, Z.A.; Jamaludin, A.R.; Sow, S.S.: Role of moisturising and pressing pressure on ceramic tile properties. J. Aust. Ceram. Soc. 54(1), 81–89 (2018)

Acknowledgements

This work was supported by the School of Materials and Minerals Resources Engineering, Universiti Sains Malaysia [001/PBAHAN/811212] and Ceramic Research Company Sdn Bhd [Guocera-Malaysia, REF: 2309/LD/Gen/CRC/15] for technical support and funding the research under company sponsorship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chin, C.L., Ahmad, Z.A. Optimization of Ceramic Tile Properties from Three Malaysian Clays via Statistical Mixture Design. Arab J Sci Eng 45, 275–290 (2020). https://doi.org/10.1007/s13369-019-04150-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-04150-9