Abstract

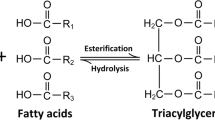

The various benefits of biofuels versus fossil fuels due to recent global challenges and issues are the best approach toward low-cost economic production of renewable energy. This study is trying to obtain economic catalysts with easy fabrication technology. The synthesized catalysts were obtained using calcium oxide/nanoclay catalysts by an initial ion-exchange reaction of calcium oxide and nanoclays (montmorillonite). These catalysts have been synthesized for the first time by being stirred for 5 h at a temperature of 80 °C, and the colloidal supernatant is obtained and kept in an ultrasonic bath for 20 min. The solution was filtered, washed several times, the residual mixture on filter paper was dried in the oven at 50 °C for few hours, and the powder was calcined for 8 h in a furnace at 600 °C. After identification and characterization, using XRD, BET, and SEM, the results approved the formation of a new nanostructure in synthesized catalysts, which were suitable to be used in biodiesel production from waste oils with high free fatty acids content. The results of this study indicate that the catalysts production process is not complicated, and methyl ester production rates in all biodiesel samples were more than 97% (97.1–98.8%).

Similar content being viewed by others

References

Vahid, B.R.; Haghighi, M.; Toghiani, J.; Alaei, S.: Hybrid-coprecipitation vs. combustion synthesis of Mg–Al spinel based nanocatalyst for efficient biodiesel production. Energy Convers. Manag. 160, 220–229 (2018). https://doi.org/10.1016/j.enconman.2018.01.030

Liati, A.; Spiteri, A.; Eggenschwiler, P.D.; Vogel-Schäuble, N.: Microscopic investigation of soot and ash particulate matter derived from biofuel and diesel: implications for the reactivity of soot. J. Nanopart. Res. 14(1224), 1–18 (2012)

Alaei, S.; Haghighi, M.; Toghiani, J.; Rahmani Vahid, B.: Magnetic and reusable MgO/MgFe2O4 nanocatalyst for biodiesel production from sunflower oil: influence of fuel ratio in combustion synthesis on catalytic properties and performance. Ind. Crops Prod. 117, 322–332 (2018). https://doi.org/10.1016/j.indcrop.2018.03.015

Taufiqurrahmi, N.; Mohamed, A.; Bhatia, S.: Nanocrystalline zeolite beta and zeolite Y as catalysts in used palm oil cracking for the production of biofuel. J. Nanopart. Res. 13(8), 3177–3189 (2011). https://doi.org/10.1007/s11051-010-0216-8

Shajaratun Nur, Z.A.; Taufiq-Yap, Y.H.; Rabiah Nizah, M.F.; Teo, S.H.; Syazwani, O.N.; Islam, A.: Production of biodiesel from palm oil using modified Malaysian natural dolomites. Energy Convers. Manag. 78, 738–744 (2014). https://doi.org/10.1016/j.enconman.2013.11.012

Halek, F.; Delavari, A.; Kavousi-rahim, A.: Production of biodiesel as a renewable energy source from castor oil. Clean Technol. Environ. Policy 15(6), 1063–1068 (2013). https://doi.org/10.1007/s10098-012-0570-6

Dawodu, F.A.; Ayodele, O.; Xin, J.; Zhang, S.; Yan, D.: Effective conversion of non-edible oil with high free fatty acid into biodiesel by sulphonated carbon catalyst. Appl. Energy 114, 819–826 (2014). https://doi.org/10.1016/j.apenergy.2013.10.004

Mata, T.; Martins, A.; Caetano, N.: Valorization of waste frying oils and animal fats for biodiesel production. In: Lee, J.W. (ed.) Advanced Biofuels and Bioproducts, pp. 671–693. Springer, New York (2013)

Zayadan, B.K.; Purton, S.; Sadvakasova, A.K.; Userbaeva, A.A.; Bolatkhan, K.: Isolation, mutagenesis, and optimization of cultivation conditions of microalgal strains for biodiesel production. Russ. J. Plant Physiol. 61(1), 124–130 (2014). https://doi.org/10.1134/S102144371401018X

Nautiyal, P.; Subramanian, K.A.; Dastidar, M.G.: Production and characterization of biodiesel from algae. Fuel Process. Technol. 120, 79–88 (2014). https://doi.org/10.1016/j.fuproc.2013.12.003

Gude, V.; Grant, G.; Patil, P.; Deng, S.: Biodiesel production from low cost and renewable feedstock. Cent. Eur. J. Eng. 3(4), 595–605 (2013). https://doi.org/10.2478/s13531-013-0102-0

Dalai, A.; Issariyakul, T.; Baroi, C.: Biodiesel production using homogeneous and heterogeneous catalysts: a review. In: Guczi, L., Erdôhelyi, A. (eds.) Catalysis for Alternative Energy Generation, pp. 237–262. Springer, New York (2012)

Ianchis, R.; Corobea, M.C.; Donescu, D.; Rosca, I.D.; Cinteza, L.O.; Nistor, L.C.; Vasile, E.; Marin, A.; Preda, S.: Advanced functionalization of organoclay nanoparticles by silylation and their polystyrene nanocomposites obtained by miniemulsion polymerization. J. Nanopart. Res. 14(11), 1–12 (2012). https://doi.org/10.1007/s11051-012-1233-6

Wong, A.; Wijnands, S.L.; Kuboki, T.; Park, C.: Mechanisms of nanoclay-enhanced plastic foaming processes: effects of nanoclay intercalation and exfoliation. J. Nanopart. Res. 15(8), 1–15 (2013). https://doi.org/10.1007/s11051-013-1815-y

Tsai, C.J.; White, D.; Rodriguez, H.; Munoz, C.; Huang, C.-Y.; Tsai, C.-J.; Barry, C.; Ellenbecker, M.: Exposure assessment and engineering control strategies for airborne nanoparticles: an application to emissions from nanocomposite compounding processes. J. Nanopart. Res. 14(7), 1–14 (2012). https://doi.org/10.1007/s11051-012-0989-z

De Maria, A.; Aurora, A.; Montone, A.; Tapfer, L.; Pesce, E.; Balboni, R.; Schwarz, M.; Borriello, C.: Synthesis and characterization of PMMA/silylated MMTs. J. Nanopart. Res. 13(11), 6049–6058 (2011). https://doi.org/10.1007/s11051-011-0496-7

Adams, J.M.; Clapp, T.V.; Clement, D.E.: Catalysis by montmorillonites. Clay Miner. 18(4), 411–421 (1983). https://doi.org/10.1180/claymin.1983.018.4.06

Shah, K.; Parikh, J.; Dholakiya, B.; Maheria, K.: Fatty acid methyl ester production from acid oil using silica sulfuric acid: process optimization and reaction kinetics. Chem. Pap. 68(4), 472–483 (2014). https://doi.org/10.2478/s11696-013-0488-4

Jeenpadiphat, S.; Tungasmita, D.N.: Esterification of oleic acid and high acid content palm oil over an acid-activated bentonite catalyst. Appl. Clay Sci. 87, 272–277 (2014). https://doi.org/10.1016/j.clay.2013.11.025

Zatta, L.; Ramos, L.P.; Wypych, F.: Acid-activated montmorillonites as heterogeneous catalysts for the esterification of lauric acid acid with methanol. Appl. Clay Sci. 80–81, 236–244 (2013). https://doi.org/10.1016/j.clay.2013.04.009

Soetaredjo, F.E.; Ayucitra, A.; Ismadji, S.; Maukar, A.L.: KOH/bentonite catalysts for transesterification of palm oil to biodiesel. Appl. Clay Sci. 53(2), 341–346 (2011). https://doi.org/10.1016/j.clay.2010.12.018

Zanette, A.F.; Barella, R.A.; Pergher, S.B.C.; Treichel, H.; Oliveira, D.; Mazutti, M.A.; Silva, E.A.; Oliveira, J.V.: Screening, optimization and kinetics of Jatropha curcas oil transesterification with heterogeneous catalysts. Renew. Energy 36(2), 726–731 (2011). https://doi.org/10.1016/j.renene.2010.08.028

Kansedo, J.; Lee, K.T.; Bhatia, S.: Cerbera odollam (sea mango) oil as a promising non-edible feedstock for biodiesel production. Fuel 88(6), 1148–1150 (2009). https://doi.org/10.1016/j.fuel.2008.12.004

Mohamadpanah, T.; Kazemzad, M.; Halek, F.: Improvement of biodiesel production reaction using functionalized spherical mesoporous silica CM-41 and HMS. J. Middle East Appl. Sci. Technol 8, 366–370 (2014)

Ali, I.; AlGhamdi, K.; Al-Wadaani, F.T.: Advances in iridium nano catalyst preparation, characterization and applications. J. Mol. (2019). https://doi.org/10.1016/j.molliq.2019.02.050

Acknowledgements

The authors would like to express their sincere appreciation to Department of Energy and Environment, Materials, and Energy Research Center (MERC) of Iran, Department of Social and Preventive Medicine, Faculty of Medicine University of Malaya (Partnership Project RK003-2017), for providing the required dataset for this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Halek, F., Aghamohammadi, N. & Mohamadi, F. Biodiesel Production from Waste Edible Oil with Heterogeneous Catalysts (Nanoclay-Based Nanocatalysts). Arab J Sci Eng 44, 9919–9924 (2019). https://doi.org/10.1007/s13369-019-03986-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-03986-5