Abstract

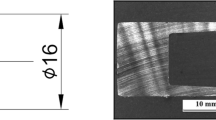

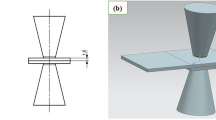

Resistance spot welding of 0.6-mm-thick AA 5052-H32 was performed within a selected range of parameters. The microstructure, nugget size and tensile shear strength (TSS) of the weldments were investigated. The TSS (ranging between 17 and 108 MPa) showed a positive dependency on the nugget diameter (ranging between 1.33 and 3.01 mm). The two weld qualities increased with increasing the welding current and decreasing electrode tip diameter. The nuggets exhibited hump-like shape which was caused by the variation in the heat generated at the two electrode terminals. Optimum parameters were found at electrode tip diameter of 4 mm, welding current of 8 kVA and welding time of 90 ms giving TSS of ~ 119 MPa. The optimal setting is suitable for aerospace applications because the corresponding nugget size met the AWS-D17.2 standard. Analysis of variance revealed that the weld current has the most significant effect on the tensile shear strength and nugget diameter with over 74% contribution.

Similar content being viewed by others

References

Zhang, W.; Sun, D.; Han, L.; Li, Y.: Optimised design of electrode morphology for novel dissimilar resistance spot welding of aluminium alloy and galvanised high strength steel. Mater. Des. 85, 461–470 (2015)

Florea, R.S.; Bammann, D.J.; Yeldell, A.; Solanki, K.N.; Hammi, Y.: Welding parameters influence on fatigue life and microstructure in resistance spot welding of 6061-T6 aluminum alloy. Mater. Des. 45, 456–465 (2013)

Zhang, X.; Zhang, J.; Chen, F.; Yang, Z.; He, J.: Characteristics of resistance spot welded Ti6Al4V titanium alloy sheet. Metals 7, 2–12 (2017). https://doi.org/10.3390/met7100424

Budiono, Y.K.; Martowibowo, S.Y.: Optimization of resistance spot welding process using response surface methodology and simulated annealing. Manuf. Technol. 17(4), 434–440 (2017)

Vinas, J.; Kascak, L.; Gres, M.: Optimisation of resistance spot welding parameters for microalloyed steel sheet. Open Eng. 6, 504–510 (2016)

Vignesh, K.; Perumal, A.E.; Velmurugan, P.: Optimisation of resistance spot welding process parameters and microstructural examination for dissimilar welding of AISI 316L austenitic stainless steel and 2205 duplex stainless steel. Int. J. Adv. Manuf. Technol. 93, 455–465 (2017)

Alizadeh-sh, M.; Marashi, S.P.H.: Resistance spot welding of dissimilar austenitic/duplex stainless steels: microstructural evolution and failure mode analysis. J. Manuf. Process. 28(1), 186–196 (2017)

Thakur, A.G.; Nandedkar, V.M.: Optimization of the resistance spot welding process of galvanized steel sheet using the Taguchi method. Arab. J. Sci. Eng. 39, 1171–1176 (2014)

Summerville, C.; Adams, D.; Compston, P.; Doolan, M.: Nugget diameter in resistance spot welding: a comparison between a dynamic resistance based approach and ultrasound C-scan. Procedia Eng. 183, 257–263 (2017)

Chen, S.; Sun, T.; Jiang, X.; Qi, J.; Zeng, R.: Online monitoring and evaluation of the weld quality of resistance spot welded titanium alloy. J. Manuf. Process. 23, 183–191 (2016)

Han, L.; Thornton, M.; Boomer, D.; Shergold, M.: A correlation study of mechanical strength of resistance spot welding of AA5754 aluminium alloy. J. Mater. Process. Technol. 211, 513–521 (2011)

Manladan, S.M.; Yusof, F.; Ramesh, S.; Fadzil, M.; Ao, S.: A review on resistance spot welding of aluminium alloys. Int. J. Adv. Manuf. Technol. 90, 605–634 (2017)

Kim, J.-S.; Kim, I.-J.; Kim, Y.-G.: Optimization of welding current waveform for dissimilar material with DP590 and Al5052 by Delta-spot welding process. J. Mech. Sci. Technol. 30(6), 2713–2721 (2016)

Zhang, Z.; Yang, X.; Zhang, J.; Zhou, G.; Xu, X.; Zou, B.: Effect of welding parameters on microstructure and mechanical properties of friction stir spot welded 5052 aluminium alloy. Mater. Des. 32(8–9), 4461–4470 (2011)

Florea, R.S.; Solanki, K.N.; Bammann, D.J.; Baird, J.C.; Jordon, J.B.; Castanier, M.P.: Resistance spot welding of 6061-T6 aluminum: failure loads and deformation. Mater. Des. 34, 624–630 (2012)

Pereira, A.M.; Ferreira, J.M.; Loureiro, A.; Costa, J.D.M.; Bártolo, P.J.: Effect of process parameters on the strength of resistance spot welds in 6082-T6 aluminium alloy. Mater. Des. 31, 2454–2463 (2010)

Hassanifard, S.; Feyzi, M.: Analytical solution of temperature distribution in resistance spot welding. J. Mech. Sci. Technol. 29(2), 777–784 (2015)

Rashid, M.; Medley, J.B.; Zhou, Y.: Nugget formation and growth during resistance spot welding of aluminium alloy 5182. Can. Metall. Q. 50(1), 61–71 (2011). https://doi.org/10.1179/000844311X552322

Sedighi, M.; Afshari, D.; Nazari, F.: Investigation of the effect of sheet thickness on residual stresses in resistance spot welding of aluminium sheets. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 232(4), 621–638 (2016)

Shanavas, S.; Dhas, J.E.R.; Murugan, N.: Weldability of marine grade AA 5052 aluminum alloy by underwater friction stir welding. Int. J. Adv. Manuf. Technol. 95, 4535–4546 (2018)

Moshwan, R.; Yusof, F.; Hassan, M.A.; Rahmat, S.M.: Effect of tool rotational speed on force generation, microstructure and mechanical properties of friction stir welded Al–Mg–Cr–Mn (AA 5052-O) alloy. Mater. Des. 66, 118–128 (2015)

Mohd Hanapi, M.H.; Zuhailawati, H.; Almanar, I.P.; Anasyida, A.S.: Optimization processing parameter of 6061-T6 alloy friction stir welded using Taguchi technique. Mater. Sci. Forum 840, 294–298 (2016)

Abioye, T.E.; Medrano-Tellez, A.; Farayibi, P.K.; Oke, P.K.: Laser metal deposition of multi-track walls of 308LSi stainless steel. Mater. Manuf. Process. 32(14), 1660–1666 (2017). https://doi.org/10.1080/10426914.2017.1292034

Chen, W.; Molian, P.: Dual-beam laser welding of ultra-thin AA 5052-H19 aluminum. Int. J. Adv. Manuf. Technol. 39, 889–897 (2008)

Wang, B.; Hua, L.; Wang, X.; Song, Y.; Liu, Y.: Effects of electrode tip morphology on resistance spot welding quality of DP590 dual-phase steel. Int. J. Adv. Manuf. Technol. 83, 1917–1926 (2016)

Arunchai, T.; Sonthipermpoon, K.; Apichayakul, P.; Tamee, K.: Resistance spot welding optimization based on artificial neural network. Int. J. Manuf. Eng. 2014, 1–6 (2014)

Cao, X.; Xiao, M.; Jahazi, M.; Fournier, J.; Alain, M.: Optimization of processing parameters during laser cladding of ZE41A-T5 magnesium alloy castings using Taguchi method. Mater. Manuf. Process. 23(4), 413–418 (2008). https://doi.org/10.1080/10426910801940391

Rao, S.S.; Chhibber, R.; Arora, S.K.; Shome, M.: Resistance spot welding of galvannealed high strength interstitial free steel. J. Mater. Process. Technol. 246, 252–261 (2017)

El-Batahgy, A.; Kutsuna, M.: Laser beam welding of AA5052, AA5083, and AA6061 aluminum alloys. Adv. Mater. Sci. Eng. 2009, 1–9 (2009)

Farayibi, P.K.; Abioye, T.E.; Clare, A.T.: A parametric study on laser cladding of Ti–6Al–4 V wire and WC/W2C powder. Int. J. Adv. Manuf. Technol. 87, 3349–3358 (2016). https://doi.org/10.1007/s00170-016-8743-9

Acknowledgements

The authors would like to thank Universiti Sains Malaysia for funding this study under RUI Grant no. (1001/PBahan/8014105).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abioye, T.E., Anas, N.M., Irfan, M.K. et al. Parametric Optimization for Resistance Spot-Welded Thin-Sheet Aluminium Alloy 5052-H32. Arab J Sci Eng 44, 7617–7626 (2019). https://doi.org/10.1007/s13369-019-03869-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-03869-9