Abstract

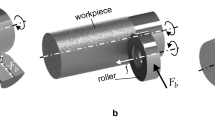

Slide burnishing (SB) is a simple and efficient method for finishing symmetric rotary metal parts. The thermo-mechanical nature of SB has not been studied in the literature and is, therefore, an object of investigation in this article. A combination of finite element method (FEM) analyses and experiments is used, and a very important part of building the FEM model is the constitutive model of the surface layer of the workpiece being slide burnished. A temperature-dependent, nonlinear kinematic/isotropic hardening material constitutive model of the surface layer of 37Cr4 steel has been modelled on the basis of temperature-dependent indentation tests and inverse FEM analyses. In order to illustrate the benefits of this thermo-mechanical constitutive model, 3D FEM simulations of the SB of holes have been conducted; doing so establishes the effect of the generated temperature on the residual hoop stress distribution around the processed hole. Fully coupled thermal stress, sequentially coupled, and temperature-independent FEM simulations have been conducted to determine the residual hoop stresses. Alternatively, these stresses are experimentally obtained through the modified “split ring” method. It has been proven that a sequentially coupled thermal stress FEM simulation with nonlinear kinematic/isotropic hardening predicts the residual hoop stresses in such a manner as to be in satisfactory agreement with the experimental outcomes. It has been established that the generated temperature reduces the beneficial effect from the introduced residual stresses, thus reducing the fatigue life of the corresponding structural component.

Similar content being viewed by others

References

Fouad, Y.; Mhaede, M.; Wagner, L.: Effects of mechanical surface treatments on fatigue performance of extruded ZK60 alloy. Fatigue Fract. Eng. Mater. Struct. 34, 403–407 (2010)

Korzynski, M.: Slide diamond burnishing. In: Korzynski, M. (ed.) Nonconventional Finishing Technologies, pp. 9–33. Polish Scientific Publishers PWN, Warsaw (2013)

Maximov, J.T.; Anchev, A.P.; Dunchev, V.P.; Ganev, N.; Duncheva, G.V.; Selimov, K.F.: Effect of slide burnishing on fatigue performance of 2024–T3 high-strength aluminium alloy. Fatigue Fract. Eng. Mater. Struct. 40(11), 1893–1904 (2017)

Maximov, J.T.; Anchev, A.P.; Duncheva, G.V.; Ganev, N.; Selimov, K.F.: Influence of the process parameters on the surface roughness, micro-hardness, and residual stresses in slide burnishing of high-strength aluminum alloys. J Braz. Soc. Mech. Sci. Eng. 39(8), 3067–3078 (2017)

Korzynski, M.; Lubas, J.; Swirad, S.; Dudek, K.: Surface layer characteristics due to slide diamond burnishing with a cylindrical: ended tool. J. Mater. Process. Technol. 211(1), 84–94 (2011)

Korzynski, M.: Modeling and experimental validation of the force: surface roughness relation for smoothing burnishing with a spherical tool. Int. J. Mach. Tool Manuf. 47(12–13), 1956–1964 (2007)

Korzynski, M.: A model of smoothing slide ball burnishing and an analysis of the parameter interaction. J. Mater. Process. Technol. 209(1), 625–633 (2009)

Korzynski, M.; Pacana, A.; Cwanek, J.: Fatigue strength of chromium coated elements and possibility of its improvement with slide diamond burnishing. Surf. Coat. Tech. 203(12), 1670–1676 (2009)

Konefal, K.; Korzynski, M.; Byczkowska, Z.; Korzynska, K.: Improved corrosion resistance of stainless steel X6CrNiMoTi17-12-2 by slide diamond burnishing. J. Mater. Process. Technol. 213(11), 1997–2004 (2013)

Korzynski, M.; Zarski, T.: Slide diamond burnishing influence on surface stereometric structure of an AZ91 alloy. Surf. Coat. Tech. 307((Part A)), 590–595 (2016)

Hongyun, L.; Jianying, L.; Lijiang, W.; Qunpeng, Z.: Investigation of the burnishing process with PCD on non-ferrous metals. Int. J. Adv. Manuf. Technol. 25(5–6), 454–459 (2005)

Hongyun, L.; Jianying, L.; Lijiang, W.; Qunpeng, Z.: The effect of burnishing parameters on burnishing force and surface microhardness. Int. J. Adv. Manuf. Technol. 28(7–8), 707–713 (2006)

Iwamoto, T.; Tanaka, H.; Yanagi, K.: An experimental study on diamond burnishing tool wear and its lifetime estimation. In: Proceedings of the International Conference on Technology of Plasticity ICTP’2011, Aachen, 2011, pp 82-86 (2011)

Luo, H.; Wang, L.; Zhang, C.: Study on the aluminum alloy burnishing processing and the existence of the outstripping phenomenon. J. Mater. Process. Technol. 116, 88–90 (2001)

Nestler, A.; Schubert, A.: Effect of machining parameters on surface properties in slide diamond burnishing of aluminium matrix composites. Mater. Today Proc. 2S, S156–S161 (2015)

Yu, X.; Wang, L.: Effect of various parameters on the surface roughness of an aluminium alloy burnished with a spherical surfaced polycrystalline diamond tool. Int. J. Mach. Tools Manuf. 39, 459–469 (1999)

Maximov, J.T.; Anchev, A.P.; Duncheva, G.V.: Modeling of the friction in the tool-workpiece system in diamond burnishing process. Coupl. Syst. Mech. 4(4), 279–295 (2015)

McMahou, C.J.; Graham, C.D.: Introduction to Engineering Materials: The bicycle and the Walkman. Merion Books, Upper Merion (1992)

Sartkulvanich, P.: Determination of material properties for use in FEM simulations of machining and roller burnishing. Dissertation, The Ohio State University (2007)

Yen, Y.C.; Sartkulvanich, P.; Altan, T.: Finite element modeling of roller burnishing process. CIRP Ann. Manuf. Technol. 54(1), 237–240 (2005)

Sartkulvanich, P.; Altan, T.; Jasso, F.; Rodriguez, C.: Finite element modeling of hard roller burnishing: an analysis on the effects of process parameters upon surface finish and residual stresses. J. Manuf. Sci. Eng. 129(4), 705–716 (2007)

Dao, M.; Chollacoop, N.; van Vliet, K.J.; Venkatesh, T.A.; Suresh, S.: Computational modeling of the forward and reverse problems in instrumented sharp indentation. Acta Materialia 49, 3899–3918 (2001)

Sachs, G.: Der Nachweis Inneres Spannungen in Stangen und Rohren. Zeitschrift fur Metalkunde 19, 352 (1927). (In German)

Maximov, J.T.; Duncheva, G.V.; Anchev, A.P.; Amudjev, I.M.; Kuzmanov, V.T.: Enhancement of fatigue life of rail-end-bolt holes by slide diamond burnishing. Eng. Solid Mech. 2(4), 247–264 (2014)

Acknowledgements

This work was supported by the Bulgarian Ministry of Education and Science and the Technical University of Gabrovo under Contract No. 1701M/2017.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maximov, J.T., Duncheva, G.V. & Anchev, A.P. A Temperature-Dependent, Nonlinear Kinematic/Isotropic Hardening Material Constitutive Model of the Surface Layer of 37Cr4 Steel Subjected to Slide Burnishing. Arab J Sci Eng 44, 5851–5862 (2019). https://doi.org/10.1007/s13369-019-03765-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-03765-2