Abstract

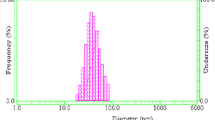

The water-based drill-in fluid should be designed to have a good carrying capacity (yield point) and an ideal filter cake (thin, impermeable, and fast formed). The ideal filter cake will reduce the fluid loss and decrease the formation damage. In addition, thin filter cake will help avoid the common drilling problem such as differential sticking and this will reduce the total drilling cost. The common drilling fluid additive that can be used to minimize the fluid loss is starch, which has two unique features, environmentally friendly and cheap additive. The aim of this paper is to assess the effect of using the micronized starch as a fluid loss control additive to the drilling fluid. Different starch sizes were used such as \(60\,\upmu \hbox {m}\), \(7\,\upmu \hbox {m}\), and \(1\,\upmu \hbox {m}\). Laboratory measurements using gas chromatography, field emission scanning electron microscope, and transmission electron microscopy were used to evaluate the micronized properties. High-pressure high-temperature filtration device was used to assess the filtration properties at \(250\,^{\circ }\hbox {F}\) and 500 psi. The effect of starch size on the drilling fluid rheological properties such as gel strength, yield point, apparent viscosity, and plastic viscosity was investigated at \(80\,^{\circ }\hbox {F}\). The results obtained showed that adding micronized starch to water-based drilling fluid increased the yield point and the plastic viscosity by 250% with an optimum yield point/plastic viscosity (YP/PV) ratio of 1.5. Filtration test at \(250\,^{\circ }\hbox {F}\) and 300 psi indicated that decreasing the starch size from 60 to \(1\,\upmu \hbox {m}\) resulted in reducing the fluid loss volume by 50% and decreased the filter cake thickness by 35%. These results indicated that the starch micronized-based (\(1\upmu \hbox {m}\)) drilling fluid was efficient in forming a thin, and impermeable filter cake.

Similar content being viewed by others

References

Amanullah, M.D.; Long, Yu.: Environment friendly fluid loss additives to protect the marine environment from the detrimental effect of mud additives. J. Petrol. Sci. Eng. 28(3–4), 199–208 (2005)

Mahto, V.; Sharma, V.P.: Rheological study of a water based oil well drilling fluid. J. Petrol. Sci. Eng. 45, 123–128 (2004)

Wahid, N.; Yusof, M.A.M.; Hanafi, N.H.: Optimum nanosilica concentration in synthetic based mud (SBM) for high temperature high pressure well. SPE/IATMI Asia Pacific Oil and Gas Conference and Exhibition, Society of Petroleum Engineers (2015)

Choi, M.; Prudhomme, R.K.; Scherer, G.W.: Rheological evaluation of compatibility in oil well cementing. Appl. Rheol. 27, 43354 (2017)

Wang, G.; Du, H.: Rheological properties of KCl/polymer type drilling fluids containing particulate loss prevention material. Appl. Rheol. 28, 35727 (2018)

Luo, Z.; Pei, J.; Wang, L.; Yu, P.; Chen, Z.: Influence of an ionic liquid on rheological and filtration properties of water-based drilling fluids at high temperatures. Appl. Clay Sci. 136, 96–102 (2017)

Zhang, L.-M.; Tan, Y.-B.; Li, Z.-M.: Application of a new family of amphoteric cellulose-based graft copolymers as drilling-mud additives. Colloid Polym. Sci. 277, 1001–1004 (1999)

Busch, A.; Myrseth, V.; Khatibi, M.; Skjetne, P.; Hovda, S.; Johansen, S.T.: Rheological characterization of polyanionic cellulose solutions with application to drilling fluids and cuttings transport modeling. Appl. Rheol. 28, 25154 (2018)

Ahmad, H.M.; Kamal, M.S.; Al-Harthi, M.A.: High molecular weight copolymers as rheology modifier and fluid loss additive for water-based drilling fluids. J. Mol. Liquids 252, 133–143 (2018)

Sadeghalvaad, M.; Sabbaghi, S.: The effect of the TiO\(_2\)/polyacrylamide nanocomposite on water-based drilling fluid properties. Powder Technol. 272, 113–119 (2015)

Elkatatny, S.M.; Mahmoud, M.A.; Nasr-El-Din, H.A.: Characterization of filter cake generated by water-based drilling fluids using CT scan. SPE Drill. Complet. 27(2), 282–293 (2012). https://doi.org/10.2118/144098-pa

Jerry, M. N.: Composition, environmental fates, and biological effects of water based drilling muds and cuttings discharged to the marine environment: a synthesis and annotated bibliography. Prepared for petroleum environmental research forum (PERF) and American Petroleum Institute (API) (2005)

Azouz, K.B.; Dupuis, D.; Bekkour, K.: Rheological characterizations of dispersions of clay particles in viscoelastic polymer solutions. Appl. Rheol. 20, 13041 (2010)

Elkatatny, S.M.; Mahmoud, M.; Nasr-El-Din, H.: Filter Cake Properties of Water-Based Drilling Fluids under Static and Dynamic Conditions Using CT Scan. J. Energy Resour. Technol. (2013). https://doi.org/10.1115/1.4023483

Benslimane, A.; Bekkour, K.; Francois, P.: Effect of addition of carboxymethylcellulose (CMC) on the rheology and flow properties of bentonite suspensions. Appl. Rheol. 23, 13475 (2013)

Elkatatny, S.M.: Real time prediction of rheological parameters of KCl water-based drilling fluid using artificial neural networks. Arab. J. Sci. Eng. 42(4), 1655–1665 (2017)

Nilsson, M.A.; Rothstein, J.P.: Effect of fluid rheology and sandstone permeability on enhanced oil recovery in a microfluidic sandstone device. Appl. Rheol. 25, 25189 (2015)

Elkatatny, S.M.; Zeeshan, T.; Mahmoud, M.A.: Real time prediction of drilling fluid rheological properties using artificial neural networks visible mathematical model (white box). J. Petrol. Sci. Eng. 146, 1202–1210 (2016)

Saasen, A.; Hodne, H.: Influence of vibrations on the rheological properties of drilling fluids and its consequence on solids control. Appl. Rheol. 26, 25349 (2016)

Ahmad, H.M.; Kamal, M.S.; Al-Harthi, M.A.: Rheological and filtration properties of clay-polymer systems: impact of polymer structure. Appl. Clay Sci. 160, 226–237 (2018)

Hossain, M.E.; Al-Majed, A.A.: Fundamentals of Sustainable Drilling Engineering. Scrivener Publishing LLC, Beverly (2015)

Elkatatny, S. M.; Kamal, M.S.; Alakbari, F.; Mahmoud, M.: Optimizing the rheological properties of water-based drilling fluid using clays and nanoparticles for drilling horizontal and multi-lateral wells. Appl. Rheol. (2018). https://doi.org/10.3933/ApplRheol-28-43606

Steele, C.; Al Bagoury, M.: Micronised ilmenite—a new, intermediate weight material for drilling fluids. Paper AADE-12-FTCE-12 presented at the AADE Fluids Technical Conference and Exhibition held at the Hilton Houston North Hotel, Houston, TX, 10–11 April 2012

Elkatatny, S.M.; Nasr-El-Din, H.; Al-Bagoury, M.: Properties of ilmenite water-based drilling fluids for HPHT applications. Paper SPE 16983 presented at the 6th international petroleum technology conference, Beijing, China, 26–28 March 2013

Al-Bagoury, M.: Micronized ilmenite—a non-damaging and non-sagging new weight material for drilling fluids. Paper SPE-169182 presented at the SPE Bergen, Bergen, Norway, 2 April 2014

Mohamed, A.K.; Elkatatny, S.A.; Mahmoud, M.A.; Shawabkeh, R.A.; Al-Majed, A.A.: The evaluation of micronized barite as a weighting material for completing HPHT wells. Paper SPE-183768-MS presented at the SPE middle east oil & gas show and conference. Manama, Kingdom of Bahrain, 6–9 March 2017

Rabia, H.: Well Engineering and Constructions. Entrac Consulting. ISBN: 0954108701 (2002)

Ismail, I.; Idris, K. A.: The Prospect of Utilizing Local Starches as Fluid Loss Control Agents in the Petroleum Industry. Department of Petroleum Engineering, University Technology Malaysia (1997)

Taiwo, A.; Joel, O.F.; Kazeem, A.A.: Investigation of local polymer (cassava starch) as a substitute for imported sample in viscosity and fluid loss control of water based drilling mud. ARPN J. Eng. Appl. Sci. 6(12), 43–48 (2011)

Samavati, R.; Abdullah, N.; Tahmasbi, N.K.; Hussain, S.A.; Awang, D.R.: The prospect of utilizing a cassava derivative (fufu) as a fluid loss agent in water based drilling muds. Int. J. Chem. Eng. Appl. 5(2), 161–168 (2015)

Omotioma, M.; Ejikeme, P.C.N.; Ume, J.I.: Improving the rheological properties of water based mud with the addition of cassava starch. IOSR J. Appl. Chem. 8(8), 70–73 (2015)

Sarah, A.A.; Isehunwa, S.O.: Temperature and time-dependent behaviour of a water base mud treated with maize (Zea mays) and Cassava (Manihot esculanta) Starches. J. Sci. Res. Rep. 5(7), 591–597 (2015)

Rao, M.A.; Tattiyaku, J.: Granule size and rheological behavior of heated tapioca starch dispersions. Carbohydr. Polym. 38(2), 123–132 (1999)

Hossen, M.S.; Sotome, I.; Takenaka, M.; Isobe, S.; Nakajima, M.; Okadome, H.: Effect of particle size of different crop starches and their flours on pasting properties. Jpn. J. Food Eng. 12(1), 29–35 (2011)

Bingham, E.C.: Fluidity and Plasticity. McGraw-Hill, New York (1922)

American Petroleum Institute: Purchasing Guidelines Handbook. API Specification 13A (2010). https://www.api.org/certification-programs/api-monogram-program-and-apiqr/~/media/Files/Certification/Monogram-APIQR/program-updates/13A-18th-Edition-Purch-Guidlines-R1-2011-12-06.pdf

Lyons, W.; Carter, T.; Lapeyrousse, N.J.: Formulas and Calculations for Drilling, Production and Workover, 3rd edn, pp. 101–102. Gulf Professional Publishing, Elsevier (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elkatatny, S. Enhancing the Rheological Properties of Water-Based Drilling Fluid Using Micronized Starch. Arab J Sci Eng 44, 5433–5442 (2019). https://doi.org/10.1007/s13369-019-03720-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-03720-1