Abstract

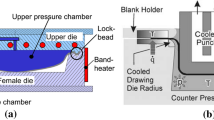

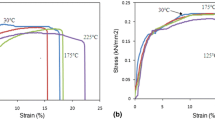

Temperature is the main effective process parameter in the warm deep drawing (WDD) process to improve the formability of light-weight engineering materials, and this feature requires the accurate measurement and assessment of temperature for process stability. In this study, an evaluation of the WDD process was conducted according to the forming temperature curves (FTCs) characterized from work piece temperatures instead of tool temperatures, as usual. To achieve this goal, a special index material was developed to accurately obtain FTCs from the work piece material under closed and heated tool conditions. The differences of temperature on work piece material are required to define temperatures by curves. The characteristic behavior of these curves was investigated under non-isothermal WDD of AA 5754-O. In the experimentation stage, the process parameters, namely FTC, blank holder force and punch velocity, which assure successful deep drawability, were determined according to the failure-free cups by analyzing wrinkling and tearing conditions and minimum cup height parameters as output parameters. As the next step, optimum conditions were investigated by evaluating the cup volume and spring-back parameters. As a general conclusion, approximately 330°C in the flange–die radius region and 100°C in the cup wall-punch bottom region are the ideal optimum temperatures for the warm deep drawing process.

Similar content being viewed by others

References

Kaya S., Spampinato G., Altan T.: An experimental study on nonisothermal deep drawing process using aluminum and magnesium alloys. J. Manuf. Sci. Eng. 130(6), 061001 (2008)

Zhang S.H., Zhang K., Xu Y.C., Wang Z.T., Yu Z.G.: Deep-drawing of magnesium alloy sheets at warm temperatures. J. Mater. Process. Technol. 185, 147–151 (2007)

Kirchain R., Cosquer A.: Strategies for maintaining light metal reuse: insights from modeling of firm-wide raw materials availability and demand. Resour. Conserv. Recycl. 51, 367–396 (2007)

Schultz, R.A.: Aluminium for light vehicles—an objective look at the next ten to twenty years. In: 14th International aluminum conference. Montreal, Canada (Ducker Research) (1999)

Kim H.S., Koç M., Ni J.: Determination of proper temperature distribution for warm forming of aluminum sheet materials. J. Manuf. Sci. Eng. 128(3), 622–33 (2006)

Altan T.; Tekkaya A.E.: Sheet Metal Forming Processes and Applications. ASM International. 978-1-61503-844-2 (2012)

Ghaffari T.D., Worswick M.J., Winkler S.: Experimental studies of deep drawing of AZ31B magnesium alloy sheet under various thermal conditions. J. Mater. Process Technol. 213, 1337–47 (2011)

Kaya, S.: Improving the formability limits of lightweight metal alloy sheet using advanced processes—finite element modeling and experimental validation. PhD thesis, University of Ohio State, Ohio (2008)

Palumbo G., Tricarico L.: Numerical and experimental investigations on the warm deep drawing process of circular aluminum alloy specimens. J. Mater. Process. Technol. 184(1), 115–23 (2007)

Kaya S., Spampinato G., Altan T.: Using servo-drive presses to determine the effect of blank holder pressure on temperature change in warm forming of sheet. J. Manuf. Sci. Eng. 133(6), 061024 (2011)

Vanden Boogaard, A.H.; Huetink, J.: Simulation of aluminium sheet forming at elevated temperatures. Comput. Method. Appl. Mech. Eng. 195, 6691–709 (2006)

Van Den Boogaard, A.H.; Huetink, J.: Modelling of aluminium sheet forming at elevated temperatures. Materials processing and design: modeling, simulation and applications, NUMIFORM. In: Proceedings of the 8th International Conference on Numerical Methods in Industrial Forming Processes, vol. 712, AIP Conference Proceedings, pp. 893–898 (2004)

Bolt, P.J.; Lamboo, N.; Rozier, P.: Feasibility of warm drawing of aluminium products. J. Mater. Process. Technol. 115(1), 118–21 (2001)

Mahabunphachai S., Koç M.: Investigations on forming of aluminum 5052 and 6061 sheet alloys at warm temperatures. J. Mater. Des. 31, 2422–34 (2010)

Shehata F.A.: Tensile behaviour of aluminium/magnesium alloy sheets at elevated temperatures. Sheet Met Indus. 63(2), 79–81 (1986)

Naka T., Yoshida F.: Deep drawability of type 5083 aluminum–magnesium alloy sheet under various conditions of temperature and forming speed. J. Mater. Process. Technol. 89/90, 19–23 (1999)

Nshama W., Jeswiet J.: Evaluation of temperature and heat transfer conditions at the metal-forming interface. CIRP Ann. Manuf. Technol. 44, 201–4 (1995)

Moon Y.H., Kang Y.K., Park J.W., Gong S.R.: Tool temperature control to increase the deep drawability of aluminum 1050 sheet. Int. J Mach. Tools Manuf. 41, 1283–94 (2001)

Chang Q.F., Li D.Y., Peng Y.H., Zeng X.Q.: Experimental and numerical study of warm deep drawing of AZ31 magnesium alloy sheet. Int. J. Mach. Tools Manuf. 47, 436–43 (2007)

Ghaffari T.D., Worswick M.J., Winkler S.: Experimental studies of deep drawing of AZ31B magnesium alloy sheet under various thermal conditions. J. Mater. Process. Technol. 213, 1337–47 (2011)

Smerd R., Winkler S., Salisbury C., Worswick M., Lloyd D.F.: High strain rate tensile testing of automotive aluminum alloy sheet. Int. J. Impact Eng. 32, 541–60 (2005)

Toros S., Ozturk F.: Modeling uniaxial, temperature and strain rate dependent behavior of Al–Mg alloys. Comput. Mater. Sci. 49, 333–9 (2010)

Ozturk F., Pekel H., Halkaci H.S.: The effect of strain rate sensitivity on formability of AA5754-O at cold and warm temperatures. J. Mater. Eng. Perform. 20(1), 77–81 (2010)

Koc M., Agcayazi A., Carsley J.: An Experimental Study on Robustness and Process Capability of the Warm Hydroforming Process. J. Manuf. Sci Eng. 133, 1–13 (2011)

Wahab A., Morsya E., Manabeb K.I.: Finite element analysis of magnesium AZ31 alloy sheet in warm deep-drawing process considering heat transfer effect. Mater. Lett. 60, 1866–1870 (2006)

Palumbo G., Sorgente D., Tricarico L.: Experimental procedure definition for evaluating the formability at warm temperatures of AZ31 magnesium alloy. Key Eng. Mater. 344, 39–46 (2007)

Kim H.S., Koc M., Ni J.: Development of an analytical model for warm deep drawing of aluminum alloys. J. Mater. Process. Technol. 197, 393–407 (2008)

Chen P., Lin Z., Chen G., Koc M.: Parametric analysis of warm forming of aluminum blanks with FEA and DOE. Trans. Nonferr. Metal Soc. 16, 267–273 (2006)

Doege E., Droder K.: Sheet metal forming of magnesium wrought alloys—formability and process technology. J. Mater. Process. Technol. 115(1), 14–9 (2001)

Capan L.: Metallere Plastik Sekil Verme, 3rd ed. Caglayan Press, Istanbul (1999)

Wang H., Luo Y.B., Friedman P., Chen M.H., Gao L.: Warm forming behavior of high strength aluminum alloy AA7075. Trans. Non-Met. Soc. 22, 1–7 (2012)

Cetin, M.H.; Turkoz, M.; Ozalp, A.F.; Yigit, O.; Arcaklıoglu, E.: Tool design including heating and cooling units for warm deep drawing process. Turkey: ISIDE Symposium (2014)

Cetin, M.H.; Yigit, O.; Gokkaya, H.; Arcaklıoglu, E.: An enhanced accuracy method for determining forming temperatures in warm deep drawing process. Turkey: ISITES Symposium (2014)

Lin Z., Wang W., Chen G.: A new strategy to optimize variable blank holder force towards improving the forming limits of aluminum sheet metal forming. J. Mater. Process. Technol. 183, 339–346 (2007)

Demirci H.I., Esner C., Yasar M.: Effect of the blank holder force on drawing of aluminum alloy square cup: theoretical and experimental investigation. J. Mater. Process. Technol. 206, 152–160 (2008)

Fan J., Tang C., Tsui C., Chan L., Lee T.: 3D finite element simulation of deep drawing with damage development. Int. J. Mach. Tools Manuf. 46(9), 1035–44 (2006)

Bagheriasl, R.: Formability of aluminum alloy sheet at elevated temperature. PhD thesis, University of Waterloo, Canada (2012)

Li D., Ghosh A.: Biaxial warm forming behavior of aluminum sheet alloys. J. Mater. Process. Technol. 145, 281–93 (2004)

Woo D.M.: On the complete solution of the deep-drawing problem. Int. J. Mech. Sci. 10, 83–94 (1968)

Halkaci H.S., Turkoz M., Dilmec M.: Enhancing formability in hydromechanical deep drawing process adding a shallow draw bead to the blank holder. J. Mater. Process. Technol. 214, 1638–1646 (2014)

Takuda H., Mori K., Masuda I., Abe Y., Matsuo M.: Finite element simulation of warm deep drawing of aluminum alloy sheet when accounting for heat conduction. J. Mater. Process. Technol. 120, 412–418 (2002)

Turkoz M., Halkacı S., Koc M.: The effect of temperature and strain-rate sensitivity on formability of AA 5754. Appl. Mech. Mater. 1596, 217–21 (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cetin, M.H., Ugur, A., Yigit, O. et al. Development of Forming Temperature Curves for Warm Deep Drawing Process Under Non-isothermal Conditions. Arab J Sci Eng 40, 2763–2784 (2015). https://doi.org/10.1007/s13369-015-1756-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-015-1756-0