Abstract

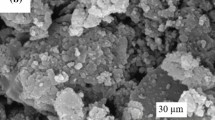

Geopolymers are produced by mixing alumino-silicate materials with alkaline activators, and the mixing process has a considerable impact on the dissolution of raw materials. This research studies the effects of mixing time, with a high-speed centrifuge mixer (1,000 rpm), on the setting and hardening properties of high calcium fly ash-based geopolymer paste. Setting time, strength, phase development, microstructure and porosity of the pastes were investigated. The results indicated that the increase in mixing time retarded the setting time which provided time for dissolution of starting materials. The optimum mixing time at high speed should be 1 min in order to obtain high strength and dense matrix in contrast to 10 min for the normal mixing. The mixing time also had an effect on the pore structure hence the total porosity of the paste.

Similar content being viewed by others

References

Guo X., Shi H., Chen L., Dick W.A.: Alkali-activated complex binders from class C fly ash and Ca-containing admixtures. J. Hazard. Mater. 173(1–3), 480–486 (2010)

Thokchom S., Mandal K.K., Ghosh S.: Effect of Si/Al ratio on performance of fly ash geopolymers at elevated temperature. Arabian J. Sci. Eng. 37, 977–989 (2012)

Palomo A., Grutzeck M.W., Blanco M.T.: Alkali-activated fly ashes: a cement for the future. Cem. Concr. Res. 29(8), 1323–1329 (1999)

Komnitsas K., Zaharaki D.: Geopolymerisation: a review and prospects for the minerals industry. Miner. Eng. 20(14), 1261–1277 (2007)

Chindaprasirt, P.; De Silva, P.; Sagoe-Crenstil, K.; Hanjitsuwan, S.: Effect of SiO2 and Al2O3 on the setting and hardening of high calcium fly ash-based geopolymer systems. J. Mater. Sci. 47(12), 4876–4883 (2012)

Phoo-ngernkham T., Chindaprasirt P., Sata V., Pangdaeng S., Sinsiri T.: Properties of high calcium fly ash geopolymer pastes containing Portland cement as additive. Int. J. Miner. Metall. Mater. 20(2), 214–220 (2013)

Lowke, D.; Schiessl, P.: Effect of mixing energy on fresh properties of SCC. In: Proceedings of the Fourth International RILEM Symposium on Self-Compacting Concrete and Second North American Conference on the Design and Use of Self-Consolidating Concrete, Chicago, USA (2005)

Davisaon J.I.: The effect of mixing time on the compressive strength of masonry mortars. Div. Build. Res. Natl. Res. Counc. Can. 114, 1–12 (1976)

Prentice L.H., Tyas M.J., Burrow M.F.: The effect of mixing time on the handling and compressive strength of an encapsulated glass-ionomer cement. Dental Materials 21(8), 704–708 (2005)

Guo X., Shi H., Dick W.A.: Compressive strength and microstructural characteristics of class C fly ash geopolymer. Cem. Concr. Compos. 32(2), 142–147 (2010)

Rattanasak U., Chindaprasirt P.: Influence of NaOH solution on the synthesis of fly ash geopolymer. Miner. Eng. 22(12), 1073–1078 (2009)

Van Jaarsveld J.G.S., Van Deventer J.S.J., Lukey G.C.: The characterisation of source materials in fly ash-based geopolymers. Mater. Lett. 57(7), 1272–1280 (2003)

Yip C.K., Lukey G.C., Provis J.L., van Deventer J.S.J.: Effect of calcium silicate sources on geopolymerisation. Cem. Concr. Res. 38(4), 554–564 (2008)

ASTM C305: Standard practice for mechanical mixing of hydraulic cement pastes and mortars of plastic consistency. Annual Book of ASTM Standard, Vol. 04.01 (2005)

Rickard W.D.A., Van Riessen A., Walls P.: Thermal character of geopolymers synthesized from class F FA containing high concentrations of iron and alpha quartz. Int. J. Appl. Ceram. Technol. 7(1), 81–88 (2010)

Temuujin J., van Riessen A.: Effect of fly ash preliminary calcination on the properties of geopolymer. J. Hazard. Mater. 164(2–3), 634–639 (2009)

Temuujin J., van Riessen A., MacKenzie K.J.D.: Preparation and characterisation of fly ash based geopolymer mortars. Constr. Build. Mater. 24(10), 1906–1910 (2010)

Hanjitsuwan, S.; Silva, D.P.; Chindaprasirt, P.: Effect of speed and time of mixing in setting time and strength of high calcium fly ash geopolymer. In: Paper Presented at the 4th KKU International Conference 2012 (KKU-IENC 2012), Khon Kaen, Thailand (2012)

Chindaprasirt P., Chareerat T., Sirivivatnanon V.: Workability and strength of coarse high calcium fly ash geopolymer. Cem. Concr. Compos. 29(3), 224–229 (2007)

ASTM C191: Standard test method for time of setting of hydrualic cement by vicat needle. Annual Book of ASTM Standard, Vol. 04.01 (2008)

ASTM C109: Standard test method of compressive strength of hydrualic cement mortars (using 2-in. or [50 mm] cube speciments). Annual Book of ASTM Standard, Vol. 04.01 (2002)

Rattanasak U., Pankhet K., Chindaprasirt P.: Effect of chemical admixtures on properties of high-calcium fly ash geopolymer. Int. J. Miner. Metall. Mater. 18(3), 364–369 (2011)

Silva, P.D.; Sagoe-Crenstil, K.: Medium-term phase stability of Na2O–Al2O3–SiO2–H2O geopolymer systems. Cem. Concr. Res. 38(6), 870–876 (2008)

Silva, P.D.; Sagoe-Crenstil, K.; Sirivivatnanon, V.: Kinetics of geopolymerization: role of Al2O3 and SiO2. Cem. Concr. Res. 37(4), 512–518 (2007)

Pimraksa K., Hanjitsuwan S., Chindaprasirt P.: Synthesis of belite cement from lignite fly ash. Ceram. Int. 35(6), 2415–2425 (2009)

Chindaprasirt P., Chareerat T., Hatanaka S., Cao T.: High strength geopolymer using fine high calcium fly ash. J. Mater. Civ. Eng. 23(3), 264–270 (2011)

Na Wittayanan, R.: The effect of pre-dissolution time to geopolymer properties. Master Thesis, Kasetsart University (2009)

Favier, A.; Habert, G.; d’Espinose de Lacaillerie, J.B., Roussel, N.: Mechanical properties and compositional heterogeneities of fresh geopolymer pastes. Cem. Concr. Res. 48(0), 9–16 (2013)

Poulesquen A., Frizon F., Lambertin D.: Rheological behavior of alkali-activated metakaolin during geopolymerization. J. Non-Cryst. Solids 357(21), 3565–3571 (2011)

Romagnoli, M.; Leonelli, C.; Kamse, E.; Gualtieri, M.L.: Rheology of geopolymer by DOE approach. Constr. Build. Mater. 36(0), 251–258 (2012)

Lecomte I., Henrist C., Liegeois M., Maseri F., Rulmont A., Cloots R.: (Micro)-structural comparison between geopolymers, alkali-activated slag cement and Portland cement. J. Eur. Ceram. Soc. 26, 3789–3797 (2006)

Somna, K.; Jaturapitakkul, C.; Kajitvichyanukul, P. Chindaprasirt, P.: NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 90(6), 2118–2124 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chindaprasirt, P., De Silva, P. & Hanjitsuwan, S. Effect of High-Speed Mixing on Properties of High Calcium Fly Ash Geopolymer Paste. Arab J Sci Eng 39, 6001–6007 (2014). https://doi.org/10.1007/s13369-014-1217-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-014-1217-1