Abstract

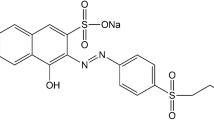

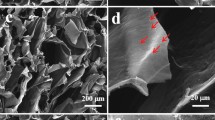

A modified sponge iron was prepared by chemical replacement copper plating using hydroxyl ethidene phosphonic acid (HEDP) as Cu(II) complexing agent in this paper. The morphology, chemical composition and surface area were characterized by scanning electron microscopy, energy dispersive spectrometer and Brunauer–Emmett–Teller area test, respectively. The results show that the sponge iron deoxygenation performance can be improved obviously by modifying with chemical replacement copper plating. The deoxygenation performance at first increases, and then reaches a maximum before decreasing as the modifying condition. Generally, the residual dissolved oxygen levels decrease with increased copper content rather than surface area. The maximum performance correlates well with maximum copper content, a condition which is realized when selecting optimal values of concentrations, temperature and contact time during the copper plating procedure with the aid of orthogonal experiments. The optimum modifying conditions are [CuSO4] 40 g/L, [HEDP] 80 g/L, [H2SO4] 10 ml/L, modifying times 15 s and plating bath temperature 30 °C. In addition, the copper content on the optimum modified sponge iron is up to 44.22 %.

Similar content being viewed by others

References

Montague, S.C.; Voelker, B.W.: Direct reduced iron discharge system and method. US Patent, 6214086 B1, 10 April 2001

Mignard, D.; Pritchard, C.A.: Review of the sponge iron process for the storage and transmission of remotely generated marine energy. Int. J. Hydrogen Energy 32, 5039–5049 (2007)

Hacker V.A.: Novel process for stationary hydrogen production: the reformer sponge iron cycle (RESC). J. Power Sour. 118, 311–314 (2003)

Hajidavalloo, E.; Alagheband, A.: Thermal analysis of sponge iron preheating using waste energy of EAF. J Mater. Process. Technol. 208, 336–341 (2008)

Zhang, X.: Study on the inner electrolysis process in pretreatment of azo dyeing wastewater with spongy iron. Dissertation, Qingdao: Ocean University of China, (2009) (In Chinese)

Moon, J.S.; Park, K.K.; Kim, J.H.; et al.: Reductive removal of dissolved oxygen in water by hydrazine over cobalt oxide catalyst supported on activated carbon fiber. Appl. Catal. A Gen. 201, 81–89 (2000)

Sinha, V.; Li, K.: Alternative methods for dissolved oxygen removal from water: a comparative study. Desalination 127, 155–164 (2000)

Heyes, A.M.: Oxygen pitting failure of a bagasse boiler tube. Eng. Fail. Anal. 8, 123–131 (2001)

Liu, L.; Ding, Z.; Chang, L.; et al.: Ultrasonic enhancement of membrane-based deoxygenation and simultaneous influence on polymeric hollow fiber membrane. Sep. Purif. Technol. 56, 133–142 (2007)

Xu, B.; Jia, M.; Men, J.: Synthesis and Properties of a Modified Sponge Iron for Removing Dissolved Oxygen. In: Advanced Materials Research, vol. 328–330, pp. 1326–1330 (2011)

Gholizadeh M.: Effect of polymer (PE–EVA–PVC) structure on gas permision properties. Arab. J. Sci. Eng. 37, 889–896 (2012)

Jahangiri, M.R.; Soltanlou, M.; Gholamipour, R.: Optimization of pre-rolling homogenizing heat treatment for cast silicon steel ingots. Arab. J. Sci. Eng. 37, 1065–1076 (2012)

Katkar, S.S.; Arbad, B.R.; Lande, M.K.: ZnO-Beta zeolite catalyzed solvent-free synthesis of polyhydroquinoline derivatives under microwave irradiation. Arab. J. Sci. Eng. 36, 39–46 (2011)

Han Ke Ping; Song Wen Bao; Wang Ji Kui; et al.: Immersion plating of bronze. Metal Finish. (11), 54–57 (1997)

Lukes R.M.: The chemistry of the autocatalytic of copper by alkaline formaldehyde. Plating 51, 1066–1068 (1964)

Scherer, M.M.; Westall, J.C.; Ziomek-Moroz, M.; et al.: Kinetics of carbon tetrachloride reduction at an oxide-free iron electrode. Environ. Sci. Technol. 31, 2385–2391 (1997)

Barstad, L.R.; Rychwaski, J.E.; Mark L.; et al.: Electrolytic copper plating solutions. US Patent: 2006/0065537 A1, 2006

Chen, L.L.: Apparatus and method for electrolytically depositing a metal on a workplace. US Patent: 6632345 B1, 2003

Choi, S.J.; Choi, J.; Seo, C.Y.; et al.: The optimal condition of acidic electroless copper plating method for Ti, Zr-based hydrogen storage alloys for electrode use. J. Alloy. Compd. 356–357, 720–724 (2003)

Sone, M.; Kobayakawa, K.; Saitou, M.; et al.: Electroless copper plating using FeII as a reducing agent. Electrochimica Acta 49, 233–238

Kondo K.; MurakamiH.: Crystal growth of electrolytic Cu foil. J. Electrochem. Soc.151(7), 514–518 (2004)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, B., Jia, M. & Men, J. Preparation, Characterization and Deoxygenation Performance of Modified Sponge Iron. Arab J Sci Eng 39, 31–36 (2014). https://doi.org/10.1007/s13369-013-0834-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-013-0834-4