Abstract

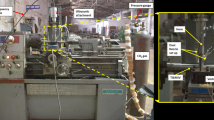

One of the old forming processes in which there is ability to produce empty parts with central symmetrical axis under acting of local and circular force is called spinning process. In cases that there is no possibility to use the process of deep drawing due to size or complex structure, spinning is a good substitute process. In metal forming processes such as spinning, temperature is one of the important parameters which must be investigated. Regarding investigation of thermo-mechanical simultaneous spinning process, no work has been done to date while some studies have been done on mechanical analysis of spinning process. In this study, the finite element method and an experimental test are used for simulation and validation of spinning process parameters for aluminum sheet. The simulation is used for two different shapes such as hemisphere and semi-conic. By comparison of numerical and experimental results it is observed that these results have suitable convergence.

Similar content being viewed by others

References

Yang C.T., Avitzur B.: Analysis of power spinning of cones. J. Eng. Ind. Trans. ASME 82, 231–245 (1960)

Kobayashi S., Thomsen E.G.: A theory of shear spinning of cones. J. Eng. Ind. Trans. ASME 83, 485–495 (1961)

Held M.: Determination of the material quality of copper shaped charge liners. Propellants Explos. Pyrotech. 10, 125–128 (1985)

Cui, S.: Discussion on the causes of scaling cracks on the outside surface of shear-spun steel conical workpiece. In: Proceedings of the Fourth International Conference of Rotary Forming, pp. 128–130 (1989)

Pack, C.L.: Metal spinning and shear and flow forming. Sheet Metal Ind, pp. 382–389 (1997)

Chen M.D.: Forecast of shear spinning force and surface roughness of spun cones by employing regression analysis. Int. J. Mach. Tools Manuf. 41, 1721–1734 (2001)

Semiatin, S.L.: ASM Handbook. In: Metalworking: Sheet Forming, vol 14B (2006)

Beni H.R., Tadi beni Y., Biglari F.R.: An experimental–numerical investigation of spinning process. Proc. IMechE Part C J. Mech. Eng. Sci. 225(3), 509–519 (2011)

Liu C.H., Wang A.C., Liang K.Z., Hsu S.E.: Analysis of conventional spinning process with thermal effects. Mater. Sci. Forum. 594, 187–192 (2008)

Quigley E., Monaghan J.: The finite element modeling of conventional spinning using multi-domain models. J. Mater. Process. Technol. 124, 360–365 (2002)

Totten, G.E.; Mackenzie, D.S.: Handbook of Aluminum. In: Physical Metallurgy and Processes, vol. 1 (2003)

TadiBeniY. Movahhedy M.R.: Consistent arbitrary Lagrangian Eulerian formulation for large deformation thermo-mechanical analysis. Mater. Design 31(8), 3690–3702 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marghmaleki, I.S., Beni, Y.T. Thermo-Mechanical Investigation of Spinning Process. Arab J Sci Eng 39, 1209–1217 (2014). https://doi.org/10.1007/s13369-013-0674-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-013-0674-2