Abstract

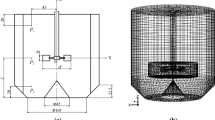

This paper presents a method for measuring the viscosity of generalized Newtonian fluid directly in flows generated by flat-blade turbine impellers, which are commonly used for moderate mixing and dispersion. A flat-blade turbine with four blades is defined as a model system and analyzed through numerical simulations with experimental verification. Carbopol 940 solution, a high viscosity non-Newtonian fluid with a yield stress, and a bentonite based drilling mud solution were selected as test fluids. Numerical simulation techniques for flow in agitators with a yield stress was established using the rotating coordinate system and flow solutions were validated with experiments by comparing the torque on the impeller shaft. The Metzner-Otto constant and the energy dissipation rate constant were predicted by numerical simulations using the Metzner-Otto correlation and validated via experiments. The effective viscosity that reproduces total energy dissipation rate identical to that of a Newtonian fluid was obtained from both numerical and experimental methods at different impeller speeds, from which the material viscosity curve was established as a function of the shear rate. The accuracy of viscosity prediction was compared with a rheological measurement and the average relative error was below 12% and 7% in the experiment and simulation, respectively. This method has the advantage of being able to measure the in-situ viscosity, where a drilling mud needs to transport more and heavier cuttings and careful preparation of the mud is key issue to a successful drilling process.

Similar content being viewed by others

References

Alexandrou, A.N., P.L. Menn, G. Georgiou, and V. Entov, 2003, Flow Instabilities of Herschel–Bulkley Fluids, J. Non-Newton. Fluid Mech.116, 19–32.

Brito-De La Fuente, E., J.A. Nava, L.M. Lopez, L. Medina, G. Ascanio, and P.A. Tanguy, 1998, Process viscometry of complex fluids and suspensions with helical ribbon agitators, Can. J. Chem. Eng.76, 689–695.

Carreau, P.J., R.P. Chhabra, and J. Cheng, 1993, Effect of rheological properties on power consumption with helical ribbon agitators, AIChE J.39, 1421–1430.

Doraiswamy, D., R.K. Gremville, and A.W. Etchells III, 1994, Two-scores years of the Metzner-Otto correlation, Ind. Eng. Chem. Res.33, 2253–2258.

Dyke. K.V., 1998, Drilling Fluids, Mud Pumps, and Conditioning Equipment, The University of Texas at Austin, U.S.A.

Edwards, M.F., J.C. Godfrey, and M.M. Kashani, 1976, Power requirement for the mixing of thixotropic liquids, J. Non-Newton. Fluid Mech.1, 309–322.

Eriksson. I, U. Bolmstedt, and A. Axelsson, 2002, Evaluation of a helical ribbon impeller as a viscosity measuring device for fluid foods with particles, Appl. Rheol.12, 303–308.

Furukawa, H., Y. Kato, Y. Inoue, T. Kato, Y. Tada, and S. Hashimoto, 2012, Correlation of power consumption for several kinds of mixing impellers, Int. J. Chem. Eng.2012, 1–6.

Hoogendoorn, C.J. and A.P. den Hartog, 1967, Model studies on mixers in the viscous flow region, Chem. Eng. Sci.22, 1689–1699.

Housner, G.W. and D.E. Hudson, 1959, Applied Mechanics Dynamics (2nd Ed.), van Nostrand, New York, U.S.A.

Jo, H.J., H.K. Jang, Y.J. Kim, and W.R. Hwang, 2017, Process viscometry in flows of non-Newtonian fluids using an anchor agitator, Korea-Australia Rheol. J.29, 317–323.

Metzner, A.B. and R.E. Otto, 1957, Agitation of non-Newtonian fluids, AIChE J.3, 3–10.

Mitsoulis, E., 2007, Flows of Viscoplastic Materials: Models and Computations, in Rheology Review, British Society of Rheology, U.K., 135-178.

Nagata, S., M. Nishikawa, H. Tada, and S. Gotoh, 1971, Power consumption of mixing impellers in pseudoplastic liquids, J. Chem. Eng. Japan4, 72–76.

Papanastasiou, T.C., 1987, Flows of Materials with Yield, J. Rheol.31, 385–404.

Paul, E.L., V.A. Atiemo-Obeng, and S.M. Kresta, 2003, Handbook of Industrial Mixing, John Wiley & Sons, New York, U.S.A.

Rieger, F., P. Ditl and V. Novak, 1979, Vortex depth in mixed unbaffled vessels, Chem. Eng. Sci.34, 397–403.

Tanguy, P.A., F. Thibault, and E. Brito-De La Fuente, 1996, A new investigation of the Metzner-Otto concept for anchor mixing impellers, Can. J. Chem. Eng.74, 222–228.

Thakur, R.K., C. Vial, G. Djelveh, and M. Labbfi, 2004, Mixing of complex fluids with flat-bladed impellers: effect of impeller geometry and highly shear-thinning behavior, Chem. Eng. Process.43, 1211–1222.

Wichterle, K. and O. Wein, 1975, Agitation of concentrated suspensions, CHISA, B4.6, 1.

Woziwodzki, S., L. Broniarz-Press, and M. Ochowiak, 2010, Transitional mixing of shear-thinning fluids in vessels with multiple impellers, Chem. Eng. Tech.33, 1099–1106.

Acknowledgement

This work is supported by Korea Agency for Infrastructure Technology Advancement grant funded by Ministry of Land, Infrastructure and Transport (20IFIP-B133614-04, Investigation and assessement of mud flow prediction and simulation in a drill hole).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jo, H.J., Kim, Y.J. & Hwang, W.R. Comparative numerical and experimental investigation of process viscometry for flows in an agitator with a flat blade turbine impeller. Korea-Aust. Rheol. J. 32, 137–144 (2020). https://doi.org/10.1007/s13367-020-0012-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13367-020-0012-7