Abstract

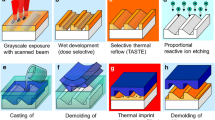

In the paper, residual-layer-free nanoimprint lithography for large-area fabrication is reviewed. In order to remove the residual layer during the imprint process, polymer resists and mold materials should be designed with the aspects of surface chemistry and mold geometries in mind. Various approaches for residual-layerfree nanoimprint lithography are discussed including incomplete filling by polymer mass, reverse imprint methods, self-removal techniques, and the employment of elastomeric mold deformation. In addition, issues that must be overcome to enable large-area roll-to-roll nanoimprinting without a residual layer are presented.

Similar content being viewed by others

References

Ahn, S., J. Cha, H. Myung, S. Kim and S. Kang, 2006, Continuous ultraviolet roll nanoimprinting process for replicating large-scale nano- and micropatterns, Appl. Phys. Lett. 89, 213101.

Ahn, S.H. and L.J. Guo, High-speed roll-to-roll nanoimprint lithography on flexible plastic substrates, 2008, Adv. Mater. 20, 2044.

Ahn, S.H. and L.J. Guo, 2009, Large area roll-to-roll and roll-toplate nanoimprint lithography: a step toward high-throughput application of continuous nanoimprinting, ACS Nano 3, 2304.

Almanza-Workman, A.M., C.P. Taussig, A.H. Jeans and R.L. Cobene, 2011, Fabrication of three-dimensional imprint lithography templates by colloidal dispersions, J. Mater. Chem. 21, 14185.

Auner, C., U. Palfinger, H. Gold, J. Kraxner, A. Haase, T. Haber, M. Sezen, W. Grogger, G. Jakopic, J.R. Krenn, G. Leising and B. Stadlober, 2009, Residue-free room temperature UVnanoimprinting of submicron organic thin film transistors, Org. Elec. 10, 1466.

Auner, C., U. Palfinger, H. Gold, J. Kraxner, A. Haase, T. Haber, M. Sezen, W. Grogger, G. Jakopic, J.R. Krenn, G. Leising and B. Stadlober, 2010, High-performing submicron organic thinfilm transistors fabricated by residue-free embossing, Organic Electronics 11 552.

Austin, M.D. and S.Y. Chou, 2002, Fabrication of 70 nm channel length polymer organic thin-film transistors using nanoimprint lithography, Appl. Phys. Lett. 81, 4431.

Bailey, T., B.J. Choi, M. Colburn, M. Meissi, S. Shaya, J.G. Ekerdt, S.V. Sreenivasan and C.G. Wilson, 2000, Step and flash imprint lithography: Template surface treatment and defect analysis, J. Vac. Sci. Technol., B 18, 3572.

Bao, L.R., X. Cheng, X.D. Huang, L.J. Guo, S.W. Pang and A.F. Yee, 2002, Nanoimprinting over topography and multilayer three-dimensional printing, J. Vac. Sci. Technol. B 20, 2881.

Bessonov, A., J.W. Seo, J.G. Kim, E.S. Hwang, J.W. Lee, J.W. Cho, D.J. Kim and S. Lee, 2011, Control over pattern fidelity and surface wettability of imprinted templates for flexible color filter manufacturing, Microelectron. Eng. 88, 2913.

Bogdanski, N., M. Wissen, A. Ziegler, and H.-C. Sheer, 2005, Instrumented indentation testing for local characterization of polymer properties after nanoimprint, Microelectron. Eng. 78–79, 598.

Cheng, X., Y. Hong, J. Kanicki and L.J. Guo, 2002, High-resolution organic polymer light-emitting pixels fabricated by imprinting technique, J. Vac. Sci. Technol. B 20, 2877.

Cheng, X. and L.J. Guo, 2004, A combined-nanoprint-and-photolithography patterning technique, Microelectron. Eng. 71, 277.

Cheng, X., D. Li and L.J. Guo, 2006, A hybrid mask-mould lithography scheme and its application in nanoscale organic thin film, Nanotechnology 17, 927.

Choi, S.J., P.J. Yoo, S.J. Beak, T.W. Kim and H.H. Lee, 2004, An ultraviolet-curable mold for sub-10-nm lithography, J. Am. Chem. Soc. 126, 7744.

Choi, S.J., D. Tahk and H. Yoon, 2009, Spontaneous dewettinginduced residue-free patterning at room temperature, J. Colloid Interf. Sci. 340, 74.

Chou, S.Y., P.R. Krauss and P.J. Renstrom, 1996, Imprint lithography with 25-nanometer resolution, Science 272, 85.

Chou, S.Y., P.R. Krauss, W. Zhang, L. Guo and L. Zhuang, 1997, Sub-10nm imprint lithography and applications, J. Vac. Sci. Technol. B, 15, 2897.

Chuang, C.H., S.W. Tsai, J.F. Lin and C.P. Chen, 2011, Fabrication of multi-functional optical films by using a ultraviolet curing roll-to-roll system, Jpn. J. Appl. Phys. 50, 06GK01.

Chung, Y.C., Y.H. Chiu, H.J. Liu, Y.F. Chang, C.Y. Cheng and F.C.N. Hong, 2006, Ultraviolet curing imprint lithography on flexible indium tin oxide substrates, J. Vac. Sci. Technol. B 24, 1377.

Clivia M. Sotomayor Torres, 2003, Alternative Lithography: Unleashing the Potentials of Nanotechnology, Kluwer Academic, 47

Colburn, M., S. Johnson, M. Stewart, S. Damle, B.J. Choi, T. Bailey, M. Wedlake, T. Michaelson, S.V. Sreenivasan, J. Ekert and C.G. Willson, 1999, Step and flash imprint lithography: a new approach to high-resolution patterning, Proc. SPIE 3676, 379.

Costner, E.A., M.W. Lin, W. Jen, and C.G. Willson, 2009, Nanoimprint lithography materials development for semiconductor device fabrication, Annu. Rev. Mater. Res. 39, 155.

de Gennes, P.-G., F. Brochard-Wyart and D. Quéré, 2004, Capillarity and Wetting Phenomena: Drops, Bubbles, Pearls, Waves, Springer, New York

Dumond, J and H.Y. Low, 2008, Residual Layer Self-Removal in Imprint Lithography, Adv. Mater. 20, 1291.

Dumond, J.J. and H.Y. Low, 2012, Recent developments and design challenges in continuous roller micro-and nanoimprinting, J. Vac. Sci. Technol. B 30, 010801.

Fagan, M.D., B.H. Kim and D.G. Yao, 2009, A novel process for continuous thermal embossing of large-area nanopatterns onto polymer films, Adv. Polym. Technol. 28, 246.

Gates, B.D. et al., 2005, New approaches to nanofabrication: molding, printing, and other techniques. Chem. Rev. 105, 1171.

Gourgon, C., C. Peret, G. Micouin, F. Lazzarino, J.H. Tortai, O. Jorbert and J.-P.E. Grolier, 2003, Influence of pattern density in nanoimprint lithography, J. Vac. Sci. Technol. B 21, 98.

Guo L.J., 2007, Nanoimprint lithography: methods and material requirements, Adv. Mater. 19, 495.

Hong, P.S., J. Kim and H.H. Lee, 2006, Contrast modified roomtemperature imprint lithography, Appl. Phys. Lett. 88, 173105.

Hu, W., E.K.F. Yim, R.M. Reano, K.W. Leong and S.W. Pang, 2005, Effects of nanoimprinted patterns in tissue-culture polystyrene on cell behavior, J. Vac. Sci. Technol. B 23, 2984.

Huang, T., J. Wu, S. Yang, P. Huang and S. Chang, 2009, Direct fabrication of microstructures on metal roller using stepped rotating lithography and electroless nickel plating, Microelectron. Eng. 86 615.

Hwang, J.K., S. Cho, J.M. Dang, E.B. Kwak, K. Song, J. Moon and M.M. Sung, 2010, Direct nanoprinting by liquid-bridgemediated nanotransfer moulding, Nat. Nanotech. 5, 742.

Kim, M.J., S. Song and H.H. Lee, 2006, A two-step dewetting method for large-scale patterning. J. Micromech. Microeng. 16, 1700.

Inannami, R., T. Ojima, K. Matsuki, T. Kono and T. Nakasugi, 2012, Sub-100 nm pattern formation by roll-to-roll nanoimprint, Proc. SPIE 8323, 83231J.

Israelachvili, J., 1992, Intermolecular & surface forces, Academic Press, London.

Jackman, R.J., D.C. Duffy, E. Ostuni, N.D. Willmore and G.M. Whitesides, 1998, Fabricating Large Arrays of Microwells with Arbitrary Dimensions and Filling Them Using Discontinuous Dewetting, Anal. Chem. 70, 2280.

Jackson, W.B., 2008, Active-matrix backplanes produced by roll-to-roll self aligned imprint lithography (SAIL), in: SID International Symposium Digest of Technical Papers 39, 322.

Jain, A. and R.T. Bonnecaze, 2013, Fluid management in roll-toroll nanoimprint lithography, J. Appl. Phys. 113, 234511.

Jeans, A., M. Almanza-Workman, R. Cobene, R. Elder, R. Garcia, F. Gomez-Pancorbo, W. Jackson, M. Jam, J.J. Kim, O. Kwon, H. Luo, J. Maltabes, P. Mei, C. Perlov, M. Smith, C. Taussig, F. Jeffrey, S. Braymen, J. Hauschildt, K. Junge, D. Larson and D. Stieler, 2010, Alternative lithographic technologies ii, Proc. SPIE 7637, 763719.

John, J., Y.Y. Tang, J.P. Rothstein, J.J Watkins and K.R. Carter, 2013, Large-area, continuous roll-to-roll nanoimprinting with PFPE composite molds, Nanotechnology 24, 505307.

Jung, G.Y., S. Ganapathiappan, X. Li, D.A.A. Ohlberg, D.L. Olynick, Y. Chen, W.M. Tong and R.S. Williams, 2004, Fabrication of molecular-electronic circuits by nanoimprint lithography at low temperatures and pressures, Appl. Phys. A: Mater. Sci. & Process. 78, 1169.

Jung, Y. and X. Cheng, 2012, Dual-layer thermal nanoimprint lithography without dry etching, J. Micromech. Microeng. 22, 085011.

Kam, A.P., J. Seekamp, V. Solovyev, C.C. Cedeno, A. Goldschmidt and C.M.S. Torres, 2004, Nanoimprinted organic field-effect transistors: fabrication, transfer mechanism and solvent effects on device characteristics, Microelectron. Eng. 73–74, 809.

Kang, M.G., H.J. Park, S.H. Ahn and L.J. Guo, 2010, Transparent Cu nanowire mesh electrode on flexible substrates fabricated by transfer printing and its application in organic solar cells, Sol. Energy Mater. Sol. Cells 94, 1179.

Kao, P.C., S.Y. Chu, C.Y. Zhan, L.C. Hsu and W.C. Liao, 2006, Fabrication of organic light-emitting devices on flexible substrates using a combined roller imprinting and photolithography-patterning technique, J. Vac. Sci. Technol. B 24, 1278.

Kao, Y.C. and F.C.N. Hong, 2011, Residual-layer-free direct printing by selective filling of a mould, J. Micromech. Microeng. 21, 025026.

Kim, E., Y. Xia and G.M. Whitesides, 1995, Making polymeric microstructures: capillary micromolding, Nature 376, 581.

Kim, E., Y. Xia, X.M. Zhao and G.M. Whitesides, 1997, Solventassisted microcontact molding: A convenient method for fabrication three-dimensional structures on surfaces of polymers, Adv. Mater. 9, 651.

Kim, K., J. Jeong, Y. Sim and E. Lee, 2006, Minimization of residual layer thickness by using the optimized dispensing method in S-FILTM process, Microelectron. Eng. 83, 847.

Kim, M.J., S. Song, S.J. Kwon and H.H. Lee, 2007, Trapezoidal Structure for Residue-Free Filling and Patterning, J. Phys. Chem. C 111, 1140.

Kim, Y.S., K.Y. Suh and H.H. Lee, 2001, Fabrication of threedimensional microstructures by soft molding, Appl. Phys. Lett. 79, 2285.

Kim, Y.S., J. Park and H.H. Lee, Three-dimensional pattern transfer and nanolithography: modified soft molding, 2002, Appl. Phys. Lett. 81, 1011.

Kim, Y. S., H.H. Lee and P.T. Hammond, 2003, High density nanostructure transfer in soft molding using polyurethane acrylate molds and polyelectrolyte multilayers. Nanotechnology 14, 1140.

Kiyohara, S., M. Fujiwara, F. Matsubayashi and K. Mori, 2005, Organic Light-Emitting Microdevices Fabricated by Nanoimprinting Technology Using Diamond Molds, Jpn. J. Appl. Phys. Part 144, 3686.

Lee, H. and G.-Y. Jung, 2005, Full wafer scale near zero residual nano-imprinting lithography using UV curable monomer solution, Microelectron. Eng. 77, 42.

Leising, G., B. Stadlober, U. Haas, A. Haase, C. Palfinger, H. Gold and G. Jakopic, 2006, Nanoimprinted devices for integrated organic electronics, Microelectron. Eng. 83, 831.

Liao, W.-C. and S.L.-C. Hsu, 2004, High aspect ratio pattern transfer in imprint lithography using a hybrid mold, J. Vac. Sci. Technol. B, 22, 2764.

Lim, H., K.B. Choi, G. Kim, S. Park, J. Ryu and J. Lee, 2011, Roller nanoimprint lithography for flexible electronic devices of a sub-micron scale, Microelectron. Eng. 88, 2017.

Mele, E., F.D. Benedetto, L. Persano, R. Cingolani and D. Pisignano, 2005, Multilevel room-temperature nanoimprint lithography for conjugated polymer-based photonics, Nano Lett. 5, 1915.

Park, H. and X. Cheng, 2009, Thermoplastic polymer patterning without residual layer by advanced nanoimprinting schemes, Nanotechnology 20, 245308.

Pisignano, D., A. Melcarne, D. Mangiullo, R. Cingolani and G. Gigili, 2004, Nanoimprint lithography of chromophore molecules under high-vacuum conditions, J. Vac. Sci. Technol. B 22, 185.

Rogers, J.A., M. Meier and A. Dodabalapur, 1998, Using Stamping and Molding Techniques to Produce Distributed Feedback and Bragg Reflector Resonators For Plastic Lasers, Appl. Phys. Lett. 73, 1766.

Rogers, J.A. and R.G. Nuzzo, 2005, Recent progress in soft lithography. Mater. Today 8, 50.

Rogers, J.A. and H.H. Lee, 2009, Unconventional Nanopatterning Techniques and Applications, Wiley, New Jersey.

Rolland, J.P., E.C. Hagberg, G.M. Denison, K.R. Carter and J.M. de Simone, 2004, High-resolution soft lithography: enabling materials for nanotechnologies, Angew. Chem. Int. Edn. 43, 5796.

Schulz, H., M. Wissen and H.-C. Scheer, 2003, Local mass transport and its effect on global pattern replication during hot embossing, Microelectron. Eng. 67–68, 657.

Seo, S.M., T.I. Kim and H.H. Lee, 2007, Simple fabrication of nanostructure by continuous rigiflex imprinting, Microelectron. Eng. 84, 567.

Stuart, C. and Y. Chen, 2009, Roll in and roll out: a path to highthroughput nanoimprint lithography ACS Nano 3, 2062.

Suh, D., S.J. Choi and H.H. Lee, 2005, Rigiflex Lithography for Nanostructure Transfer, Adv. Mater. 17, 1554.

Suh, K.Y., Y.S. Kim and H.H. Lee, 2001, Capillary Force Lithography, Adv. Mater. 13, 1386.

Suh, K.Y., J. Park and H.H. Lee, 2002, Controlled polymer dewetting by physical confinement J. Chem. Phys. 116, 7714.

Tan, H., A. Gilbertson and Y.S. Chou, 1998, Roller nanoimprint lithography, J. Vac. Sci. Technol. B 16, 3926

Vig, A.L., T. Makela, P. Majander, V. Lambertini, J. Ahopelto and A. Kristensen, 2011, Roll-to-roll fabricated lab-on-a-chip devices, J. Micromech. Microeng. 21, 035006.

Williams, S.S., S. Retterer, R. Lopez, R. Ruiz, E.T. Samulski and J.M. de Simone, 2010, High-resolution PFPE-based molding techniques for nanofabrication of high-pattern density, sub-20 nm features: a fundamental materials approach, Nano Lett. 10, 1421.

Wu, J.T. and S.Y. Yang, 2010, A gasbag-roller-assisted UV imprinting technique for fabrication of a microlens array on a PMMA substrate, J. Micromech. Microeng. 20, 085038.

Xia, Y. and G.M. Whitesides, 1995, Use of controlled reactive spreading of liquid alkanethiol on the surface of gold to modify the size of features produced by microcontact Printing, J. Am. Chem. Soc. 117, 3274.

Xia, Y. and G.M. Whitesides, 1998, Soft Lithography, Angew. Chem. Int. Ed. 37, 550.

Xia, Y., J.A. Rogers, K.E. Paul and G.M. Whitesides, 1999, Unconventional Methods for Fabricating and Patterning Nanostructures, Chem. Rev. 99, 1823.

Yang, K.Y., K.M. Yoon, J.W. Kim, J.H. Lee and H. Lee, 2009, Low Temperature Fabrication of Residue-Free Polymer Patterns on Flexible Polymer Substrate, Jpn. J. Appl. Phys. 48, 095003.

Yeo, L.P., S.H. Ng, Z.F. Wang, H.M. Xia, Z.P. Wang, V.S. Thang, Z.W. Zhong and N.F. de Rooij, 2010, Investigation of hot roller embossing for microfluidic devices, J. Micromech. Microeng. 20, 015017.

Yoon, H., K.M. Lee, D.Y. Khang, H.H. Lee and S.J. Choi, 2004, Rapid flash patterning of nanostructures, Appl. Phys. Lett. 85, 1793.

Yoon, H., M.K. Choi, K.Y. Suh and K. Char, 2010, Self-modulating polymer resist patterns in pressure-assisted capillary force lithography, J. Colloid Interf. Sci. 346, 476.

Yoon, H., S.H. Lee, S.H. Sung, K.Y. Suh and K. Char, 2011, Mold Design Rules for Residual Layer-Free Patterning in Thermal Imprint Lithography, Langmuir 27, 7944.

Youn, S.W., M. Iwara, H. Goto, M. Takahashi and R. Maeda, 2008, Prototype development of a roller imprint system and its application to large area polymer replication for a microstructured optical device, J. Mater. Process. Technol. 202, 76.

Yun, D., Y. Son, J. Kyung, H. Park, C. Park and S. Lee, 2012, Development of roll-to-roll hot embossing system with induction heater for micro fabrication, Rev. Sci. Instrum. 83 015108.

Zaumseil, J., M.A. Meitl, J.W.P. Hsu, B.R. Acharya, K.W. Baldwin, Y.L. Loo and J.A. Rogers, 2003, Three-dimensional and multilayer nanostructures formed by nanotransfer printing, Nano Lett. 3 1223.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yoon, H., Lee, H. & Lee, W.B. Toward residual-layer-free nanoimprint lithography in large-area fabrication. Korea-Aust. Rheol. J. 26, 39–48 (2014). https://doi.org/10.1007/s13367-014-0005-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13367-014-0005-5