Abstract

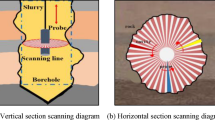

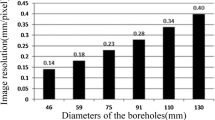

In order to ensure the borehole forming of underwater bored cast-in-place pile and the overall quality of pile foundation engineering, the rapid defect detection on the borehole wall of bored cast-in-place pile and its retaining wall is of great significance. Aiming at the problem of image acquisition and defect detection of underwater complex environment in bored pile, based on the optical image acquisition technology of underwater bored pile borehole wall, this study puts forward a defect detection method suitable for underwater bored pile borehole wall. Firstly, using the principle of underwater optical imaging, an optical image acquisition equipment suitable for the borehole wall of underwater bored cast-in-place pile is developed. Combined with the working principle of the equipment and the optical image characteristics of the defect area, the borehole wall optical image correction method is constructed, which weakens the influence of close distance and inner curvature of the borehole wall on the optical imaging. Then, by constructing the underwater optical imaging model of borehole wall defects, an underwater optical image enhancement function considering the intensity of light source and the difference in optical propagation at different wavelengths is proposed. Combined with gradient operator and maximum interclass variance method, an effective identification method for borehole wall defect area of underwater bored cast-in-place pile is formed by sharpening the edge of borehole wall defect area. Finally, three characteristic parameter pointers, target frame ratio, area and aspect ratio, and special shape, are proposed to form the search and detection method of borehole wall target defect area, which can realize the accurate defect detection of borehole wall binary image. Combined with the comparative analysis of borehole wall image processing and quantitative evaluation and analysis of borehole wall defects, it is proved that this method has accurate and efficient detection ability, which can realize the intelligent detection of optical image of borehole wall defects in the underwater bored cast-in-place pile, improve the accuracy of artificial intelligence measurement of borehole wall defect area of bored cast-in-place pile, and provide more data support for the detection and maintenance of borehole wall defects of underwater bored cast-in-place pile.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Li L, Li JP, Yue ZW (2016) Study on mechanical mechanism of borehole wall stability of bored cast-in-place pile in saturated clay. Geotech Mech 37(09):2496–2504. https://doi.org/10.16285/j.rsm.2016.09.009

Zhang RY, Zhang HY (2018) Application of bored cast-in-place pile technology in housing construction. Residential and real estate 24:181

Shen JH, Liu HQ, Yang Y (2015) borehole forming quality inspection of large diameter and super long bored pile. Highway Transport Technol (Appl Technol Edn) 11(11):167–169

Peng BJ (2016) Study on retaining wall design method of manual borehole digging pile considering borehole channeling effect. Geol Explor 52(02):307–315

Wei YG (2016) Discussion on treatment method of retaining wall collapse of manual borehole digging pile. Eng Construct Design 7:167–168172. https://doi.org/10.13616/j.cnki.gcjsysj.2016.07.045

Ali S, Tian GY, Mengbao F (2017) Pulsed Eddy current non-destructive testing and evaluation: a review. Chin J Mech Eng 30(03):500–514

Wu XJ, Zhang Q, Shen GT (2016) Overview of pulsed eddy current nondestructive testing technology. J Instrum 37(08):1698–1712. https://doi.org/10.3969/j.issn.0254-3087.2016.08.003

Saleh H, Aouni AL (2012) Application of time–frequency analysis for automatic hidden corrosion detection in a multilayer aluminum structure using pulsed eddy current. NDT E Int. https://doi.org/10.1016/j.ndteint.2011.12.001

Chen M, Chen XZ, Chen GY (2018) Ultrasonic detection of damage state of concrete filled steel tubular under axial compression. J Northeast Univ (Nat Sci Edn) 39(10):1458–1462. https://doi.org/10.12068/j.issn.1005-3026.2018.10.018

Zhang M (2018) How to improve the effect of ultrasonic testing of pile foundation. Sci Technol Innovat 9:95–96

Wang YQ, Chen YQ (2017) Identification and elimination of false defect signal in ultrasonic guided wave pipeline inspection. China Sci: Technol Sci 47(02):137–148

Li HJ (2018) Application of pipeline CCTV detection technology in urban drainage projects. Management and technology of small and medium-sized enterprises (next ten days) 2:170-171

Qi LH, Zu SQ, Ma J (2017) CCTV detection results and suggestions of a regional sewage pipe network in Zhuhai. China Water Supply Drainage 33(22):135–138

Bin C, Rong L, Wanjian B, et al (2019) Research on recognition method of optical detection image of underwater robot for submarine cable[C]. 2019 IEEE 3rd Advanced Information Management, Communicates, Electronic and Automation Control Conference (IMCEC), Chongqing, China, 1973–1976

Lecun Y, Bengio Y, Hinton G (2015) Deep learning. Nature 521(7553):436–444. https://doi.org/10.1038/nature14539

Zhang JX, Yordanov B, Gaunt A et al (2021) A deep learning model for predicting next-generation sequencing depth from DNA sequence. Nat Commun 12:4387. https://doi.org/10.1038/s41467-021-24497-8

Myrans J, Kapelan Z, Everson R (2016) Automated detection of faults in wastewater pipes from CCTV footage by using random forests. Proc Eng 154:36–41. https://doi.org/10.1016/j.proeng.2016.07.416

Yang MD, Chen YP, Su TC (2016) Sewer pipe defects diagnosis assessment using multivariate analysis on CCTV video imagery. Urban Water J 14(5):475–482. https://doi.org/10.15890/j.cnki.jsjs.2019.06.022

Wang J, Chen W, Wang Y (2021) Coral reef pore recognition and feature extraction based on borehole image. Mar Georesour Geotechnol 11:1–12. https://doi.org/10.1080/1064119X.2021.1874576

Wang J, Wang C, Han Z (2020) Characteristic Parameters Extraction Method of Hidden Karst Cave from borehole Radar Signal. Int J Geomech 20(8):04020113. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001733

Wang JC, Wang CY, Hu S, Han ZQ (2017) Research on structural plane parameter extraction method of borehole wall borehole image. Geotechn Mech 10:3074–3080. https://doi.org/10.16285/j.rsm.2017.10.038

Wang X, Xu H, Wang J (2022) Damage area identification of underwater structures based on wavelength difference of light source. J Civ Struct Heal Monit 4:1–15. https://doi.org/10.1007/s13349-022-00558-4

Wong TY, Wong MH, Lui CS (2008) A precise termination condition of the probabilistic packet marking algorithm. IEEE Trans Dependable Secure Comput 5(1):6–21. https://doi.org/10.1109/TDSC.2007.70229

Acknowledgements

This research was supported by the National Natural Science Foundation for the Youth of China (Grant No. 41902294) and the Open Projects Foundation of State Key Laboratory for Health and Safety of Bridge Structures (No. BHSKL-20-05-GF).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Liu, H. Defect detection method of underwater bored cast-in-place pile based on optical image in borehole. J Civil Struct Health Monit 14, 189–207 (2024). https://doi.org/10.1007/s13349-023-00724-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13349-023-00724-2