Abstract

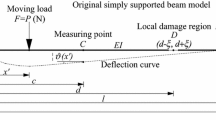

This paper proposes a novel displacement–strain transfer (DST) matrix method to estimate the local bending deformation of bridge deck using the measured strain. The DST matrix of the bi-dimensional plate with various boundary conditions is derived theoretically, and the local bending deformation of the plate can be further estimated. A plate with four simply supported edges, two simply supported edges, and one clamped edge under various load cases is simulated. The DST matrix is calculated, and the local bending deformation is finally estimated. The proposed method is also verified by the experimental test of a simply supported plate. Both the numerical and experimental results indicate that the proposed method can effectively estimate the local bending deformation of a bi-dimensional plate. Finally, a steel–concrete composite girder bridge is simulated, and the local bending deformation of the bridge deck is also effectively estimated based on the proposed method.

Similar content being viewed by others

References

Park HS, Lee HM, Adeli H, Lee I (2007) A new approach for health monitoring of structures: terrestrial laser scanning. Comput Aided Civ Infrastruct Eng 22(1):19–30. https://doi.org/10.1111/j.1467-8667.2006.00466.x

Li SL, Wang X, Liu HZ, Zhuo Y, Su W, Di H (2020) Dynamic deflection monitoring of high-speed railway bridges with the optimal inclinometer sensor placement. Smart Struct Syst 26(5):591–603. https://doi.org/10.12989/sss.2020.26.5.591

Lienhart W, Ehrhart M, Grick M (2017) High frequent total station measurements for the monitoring of bridge vibrations. J Appl Geod 11(1):1–8

Paziewski J, Sieradzki R, Baryla R (2019) Detection of structural vibration with high-rate precise point positioning: case study results based on 100 Hz multi-gnss observables and shake-table simulation. Sensors (Basel). https://doi.org/10.3390/s19224832

Zhang LX, Liu P, Yan X, Zhao XF (2020) Middle displacement monitoring of medium-small span bridges based on laser technology. Struct Control Health Monit. https://doi.org/10.1002/stc.2509

Maksymenko OP, Sakharuk OM, Ivanytskyi YL, Kun PS (2020) Multilaser spot tracking technology for bridge structure displacement measuring. Struct Control Health Monit. https://doi.org/10.1002/stc.2675

Artese S, Achilli V, Zinno R (2018) Monitoring of bridges by a laser pointer: dynamic measurement of support rotations and elastic line displacements: methodology and first test. Sensors (Basel). https://doi.org/10.3390/s18020338

Khuc T, Catbas FN (2018) Structural identification using computer vision-based bridge health monitoring. J Struct Eng. https://doi.org/10.1061/(Asce)St.1943-541x.0001925

Dong C-Z, Celik O, Catbas FN, O’Brien EJ, Taylor S (2019) Structural displacement monitoring using deep learning-based full field optical flow methods. Struct Infrastruct Eng 16(1):51–71. https://doi.org/10.1080/15732479.2019.1650078

Hoskere V, Park JW, Yoon H, Spencer BF (2019) Vision-based modal survey of civil infrastructure using unmanned aerial vehicles. J Struct Eng. https://doi.org/10.1061/(Asce)St.1943-541x.0002321

Ni YQ, Wang YW, Liao WY, Chen WH (2019) A vision-based system for long-distance remote monitoring of dynamic displacement: experimental verification on a supertall structure. Smart Struct Syst 24(6):769–781. https://doi.org/10.12989/sss.2019.24.6.769

Tian L, Zhang XH, Pan B (2019) Drift error compensation for vision-based bridge deflection monitoring. Smart Struct Syst 24(5):649–657. https://doi.org/10.12989/sss.2019.24.5.649

Dong C-Z, Catbas FN (2020) A review of computer vision–based structural health monitoring at local and global levels. Struct Health Monit. https://doi.org/10.1177/1475921720935585

Pieraccini M (2013) Monitoring of civil infrastructures by interferometric radar: a review. Sci World J. https://doi.org/10.1155/2013/786961

Stabile TA, Perrone A, Gallipoli MR, Ditommaso R, Ponzo FC (2013) Dynamic survey of the musmeci bridge by joint application of ground-based microwave radar interferometry and ambient noise standard spectral ratio techniques. IEEE Geosci Remote Sens 10(4):870–874. https://doi.org/10.1109/Lgrs.2012.2226428

Zhang Z, Huang Y, Palek L, Strommen R (2014) Glass fiber–reinforced polymer–packaged fiber Bragg grating sensors for ultra-thin unbonded concrete overlay monitoring. Struct Health Monit Int J 14(1):110–123. https://doi.org/10.1177/1475921714554143

Zhu Z, Luo S, Feng Q, Chen Y, Wang F, Jiang L (2020) A hybrid DIC–EFG method for strain field characterization and stress intensity factor evaluation of a fatigue crack. Measurement. https://doi.org/10.1016/j.measurement.2020.107498

Chen Y, Joffre D, Avitabile P (2018) Underwater dynamic response at limited points expanded to full-field strain response. J Vib Acoust. https://doi.org/10.1115/1.4039800

Vurpillot S, Krueger G, Benouaich D, Clement D, Inaudi D (1998) Vertical deflection of a pre-stressed concrete bridge obtained using deformation sensors and inclinometer measurements. ACI Struct J 95(5):518–526

Tessler A, Spangler JL (2005) A least-squares variational method for full-field reconstruction of elastic deformations in shear-deformable plates and shells. Comput Method Appl Mech 194(2–5):327–339. https://doi.org/10.1016/j.cma.2004.03.015

Kang LH, Kim DK, Han JH (2007) Estimation of dynamic structural displacements using fiber Bragg grating strain sensors. J Sound Vib 305(3):534–542. https://doi.org/10.1016/j.jsv.2007.04.037

Glaser R, Caccese V, Shahinpoor M (2012) Shape monitoring of a beam structure from measured strain or curvature. Exp Mech 52(6):591–606. https://doi.org/10.1007/s11340-011-9523-y

Rapp S, Kang LH, Han JH, Mueller UC, Baier H (2009) Displacement field estimation for a two-dimensional structure using fiber Bragg grating sensors. Smart Mater Struct. https://doi.org/10.1088/0964-1726/18/2/025006

Kim HI, Kang LH, Han JH (2011) Shape estimation with distributed fiber Bragg grating sensors for rotating structures. Smart Mater Struct. https://doi.org/10.1088/0964-1726/20/3/035011

Wang ZC, Geng D, Ren WX, Liu HT (2014) Strain modes based dynamic displacement estimation of beam structures with strain sensors. Smart Mater Struct. https://doi.org/10.1088/0964-1726/23/12/125045

Chung W, Kim S, Kim NS, Lee HU (2008) Deflection estimation of a full scale prestressed concrete girder using long-gauge fiber optic sensors. Constr Build Mater 22(3):394–401. https://doi.org/10.1016/j.conbuildmat.2006.08.007

Moore JP, Rogge MD (2012) Shape sensing using multi-core fiber optic cable and parametric curve solutions. Opt Express 20(3):2967–2973. https://doi.org/10.1364/Oe.20.002967

Iadicicco A, Della Pietra M, Alviggi M, Canale V, Campopiano S (2014) Deflection monitoring method using fiber Bragg gratings applied to tracking particle detectors. IEEE Photonics J. https://doi.org/10.1109/Jphot.2014.2352639

Xu H, Ren WX, Wang ZC (2015) Deflection estimation of bending beam structures using fiber Bragg grating strain sensors. Adv Struct Eng 18(3):395–403. https://doi.org/10.1260/1369-4332.18.3.395

Jones RT, Bellemore DG, Berkoff TA, Sirkis JS, Davis MA, Putnam MA, Friebele EJ, Kersey AD (1998) Determination of cantilever plate shapes using wavelength division multiplexed fiber Bragg grating sensors and a least-squares strain-fitting algorithm. Smart Mater Struct 7(2):178. https://doi.org/10.1088/0964-1726/7/2/005

Derkevorkian A, Masri SF, Alvarenga J, Boussalis H, Bakalyar J, Richards WL (2013) Strain-based deformation shape-estimation algorithm for control and monitoring applications. AIAA J 51(9):2231–2240. https://doi.org/10.2514/1.J052215

Xu L, Ge J, Patel JH, Fok MP (2017) Dual-layer orthogonal fiber Bragg grating mesh based soft sensor for 3-dimensional shape sensing. Opt Express 25(20):24727–24734. https://doi.org/10.1364/Oe.25.024727

Szilard R (2004) Theories and applications of plate analysis: classical, numerical and engineering methods. Appl Mech Rev 57(6):B32–B33

Di Palma P, Palumbo G, Della Pietra M, Canale V, Alviggi M, Iadicicco A, Campopiano S (2019) Deflection monitoring of bi-dimensional structures by fiber Bragg gratings strain sensors. IEEE Sens J 19(11):4084–4092. https://doi.org/10.1109/Jsen.2019.2896910

Acknowledgements

Financial support to complete this study was provided in part by the National Natural Science Foundation of China under Grand nos. 51922036, by the key research and development project of Anhui province under Grand no. 1804a0802204, by The Fundamental Research Funds for the Central Universities under Grand no. JZ2020HGPB0117, and by the Natural Science Funds for Distinguished Young Scholar of Anhui province under Grand no. 1708085J06. The results and opinions expressed in this paper are those of the authors only and they don’t necessarily represent those of the sponsors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: The calculated strain data at each measurement points for the plate with four simply supported edges

Point number | Coordinate | Strain data (με) | ||

|---|---|---|---|---|

x (mm) | y (mm) | Case1 | Case2 | |

1 | 150 | 150 | − 21.0 | − 12.6 |

2 | 150 | 350 | 19.9 | − 22.6 |

3 | 150 | 550 | 224.1 | 12.8 |

4 | 150 | 750 | 19.9 | 131.7 |

5 | 150 | 950 | − 21.0 | 83.3 |

6 | 300 | 150 | − 32.8 | − 19.6 |

7 | 300 | 350 | − 6.2 | − 41.7 |

8 | 300 | 550 | 939.7 | − 15.5 |

9 | 300 | 750 | − 6.2 | 284.0 |

10 | 300 | 950 | − 32.8 | 102.2 |

11 | 450 | 150 | − 21.0 | − 15.1 |

12 | 450 | 350 | 19.9 | − 36.5 |

13 | 450 | 550 | 224.1 | − 36.6 |

14 | 450 | 750 | 19.9 | 268.2 |

15 | 450 | 950 | − 21.0 | 47.6 |

Appendix 2: The relative error of the estimated deformation for the plate with four simply supported edges

Coordinate | Load ase1 | Load case2 | |||||

|---|---|---|---|---|---|---|---|

x (mm) | y (mm) | Calculated values (mm) | Estimated values (mm) | Errors (%) | Calculated values (mm) | Estimated values (mm) | Errors (%) |

75 | 150 | − 0.75 | − 0.72 | 3.63 | − 0.24 | − 0.23 | 1.52 |

75 | 350 | − 1.86 | − 1.82 | 2.13 | − 0.66 | − 0.64 | 2.41 |

75 | 550 | − 2.56 | − 2.46 | 3.80 | − 1.24 | − 1.27 | − 2.36 |

75 | 750 | − 1.86 | − 1.88 | − 1.06 | − 1.59 | − 1.66 | − 4.23 |

75 | 950 | − 0.75 | − 0.75 | − 0.83 | − 0.98 | − 1.00 | − 1.87 |

225 | 150 | − 1.72 | − 1.77 | − 2.64 | − 0.55 | − 0.55 | 0.62 |

225 | 350 | − 4.39 | − 4.27 | 2.86 | − 1.56 | − 1.50 | 3.88 |

225 | 550 | − 6.43 | − 6.22 | 3.31 | − 3.04 | − 3.12 | − 2.67 |

225 | 750 | − 4.39 | − 4.34 | 1.26 | − 4.21 | − 4.42 | − 4.91 |

225 | 950 | − 1.72 | − 1.81 | − 4.89 | − 2.58 | − 2.67 | − 3.30 |

375 | 150 | − 1.72 | − 1.80 | − 4.88 | − 0.56 | − 0.58 | − 2.92 |

375 | 350 | − 4.39 | − 4.43 | − 0.80 | − 1.61 | − 1.65 | − 2.50 |

375 | 550 | − 6.43 | − 6.36 | 1.02 | − 3.32 | − 3.44 | − 3.69 |

375 | 750 | − 4.39 | − 4.44 | − 1.01 | − 5.27 | − 5.41 | − 2.76 |

375 | 950 | − 1.72 | − 1.81 | − 4.94 | − 3.11 | − 3.26 | − 4.63 |

525 | 150 | − 0.75 | − 0.76 | − 1.82 | − 0.25 | − 0.25 | − 1.90 |

525 | 350 | − 1.86 | − 1.85 | 0.83 | − 0.72 | − 0.75 | − 4.57 |

525 | 550 | − 2.56 | − 2.58 | − 0.92 | − 1.53 | − 1.46 | 4.85 |

525 | 750 | − 1.86 | − 1.82 | 2.46 | − 2.48 | − 2.52 | − 1.85 |

525 | 950 | − 0.75 | − 0.78 | − 4.44 | − 1.50 | − 1.42 | 5.00 |

Appendix 3: The calculated strain at each measurement points for the plate

Point number | Coordinate | Strain data (με) | ||||

|---|---|---|---|---|---|---|

Plate with one clamped edge | Plate with two opposite simply supported edges | |||||

x (mm) | y (mm) | Load case1 | Load case2 | Load case1 | Load case2 | |

1 | 150 | 150 | − 44.6 | − 40.9 | 41.1 | 53.4 |

2 | 150 | 350 | − 35.6 | − 34.6 | 95.0 | 94.4 |

3 | 150 | 550 | − 25.3 | − 24.9 | 137.8 | 114.6 |

4 | 150 | 750 | − 14.7 | − 14.5 | 95.0 | 90.3 |

5 | 150 | 950 | − 4.2 | − 4.9 | 40.9 | 41.1 |

6 | 300 | 150 | − 44.7 | − 44.6 | 40.7 | 44.9 |

7 | 300 | 350 | − 34.5 | − 34.3 | 89.3 | 97.7 |

8 | 300 | 550 | − 25.0 | − 24.4 | 203.5 | 134.1 |

9 | 300 | 750 | − 15.1 | − 13.6 | 89.1 | 97.4 |

10 | 300 | 950 | − 4.5 | − 3.5 | 39.0 | 42.0 |

11 | 450 | 150 | − 44.6 | − 48.1 | 41.1 | 31.8 |

12 | 450 | 350 | − 35.6 | − 36.3 | 95.0 | 100.4 |

13 | 450 | 550 | − 25.3 | − 25.0 | 137.8 | 185.7 |

14 | 450 | 750 | − 14.7 | − 13.4 | 95.0 | 104.6 |

15 | 450 | 950 | − 4.2 | − 0.9 | 40.9 | 43.4 |

Appendix 4: The relative error of the estimated deformation for the plate with one clamped edge

Coordinate | Load case1 | Load case2 | |||||

|---|---|---|---|---|---|---|---|

x (mm) | y (mm) | Calculated values (mm) | Estimated values (mm) | Errors (%) | Calculated values (mm) | Estimated values (mm) | Errors (%) |

75 | 150 | − 0.21 | − 0.22 | 5.1 | − 0.16 | − 0.18 | 8.8 |

75 | 350 | − 1.11 | − 1.13 | 1.5 | − 0.93 | − 0.96 | 2.6 |

75 | 550 | − 2.60 | − 2.60 | 0.0 | − 2.26 | − 2.27 | 0.4 |

75 | 750 | − 4.49 | − 4.47 | − 0.5 | − 4.00 | − 3.98 | − 0.4 |

75 | 950 | − 6.62 | − 6.58 | − 0.6 | − 5.98 | − 5.93 | − 0.8 |

225 | 150 | − 0.24 | − 0.22 | − 6.6 | − 0.22 | − 0.21 | − 6.9 |

225 | 350 | − 1.17 | − 1.13 | − 3.6 | − 1.11 | − 1.07 | − 3.6 |

225 | 550 | − 2.66 | − 2.60 | − 2.3 | − 2.54 | − 2.49 | − 2.2 |

225 | 750 | − 4.55 | − 4.47 | − 1.7 | − 4.37 | − 4.30 | − 1.6 |

225 | 950 | − 6.68 | − 6.58 | − 1.4 | − 6.41 | − 6.34 | − 1.2 |

375 | 150 | − 0.24 | − 0.22 | − 6.6 | − 0.25 | − 0.23 | − 7.2 |

375 | 350 | − 1.17 | − 1.13 | − 3.6 | − 1.22 | − 1.18 | − 4.0 |

375 | 550 | − 2.66 | − 2.60 | − 2.3 | − 2.76 | − 2.69 | − 2.6 |

375 | 750 | − 4.55 | − 4.47 | − 1.7 | − 4.68 | − 4.59 | − 1.9 |

375 | 950 | − 6.68 | − 6.58 | − 1.4 | − 6.82 | − 6.72 | − 1.5 |

525 | 150 | − 0.21 | − 0.22 | 5.1 | − 0.26 | − 0.26 | 1.1 |

525 | 350 | − 1.11 | − 1.13 | 1.5 | − 1.29 | − 1.29 | − 0.3 |

525 | 550 | − 2.60 | − 2.60 | 0.0 | − 2.94 | − 2.90 | − 1.2 |

525 | 750 | − 4.49 | − 4.47 | − 0.5 | − 4.99 | − 4.91 | − 1.6 |

525 | 950 | − 6.62 | − 6.58 | − 0.6 | − 7.26 | − 7.13 | − 1.8 |

Appendix 5: The relative error of the estimated deformation for the plate with two opposite simply supported edges

Coordinate | Load case1 | Load case2 | |||||

|---|---|---|---|---|---|---|---|

x (mm) | y (mm) | Calculated values (mm) | Estimated values (mm) | Errors (%) | Calculated values (mm) | Estimated values (mm) | Errors (%) |

75 | 150 | − 2.38 | − 2.49 | 4.5 | − 2.16 | − 2.23 | 3.1 |

75 | 350 | − 5.24 | − 5.23 | − 0.2 | − 4.31 | − 4.32 | 0.1 |

75 | 550 | − 6.05 | − 6.00 | − 0.8 | − 5.10 | − 5.01 | − 1.7 |

75 | 750 | − 5.37 | − 5.22 | − 2.7 | − 4.25 | − 4.18 | − 1.8 |

75 | 950 | − 2.48 | − 2.48 | 0.1 | − 2.08 | − 2.05 | − 1.3 |

225 | 150 | − 2.47 | − 2.49 | 0.7 | − 2.31 | − 2.39 | 3.6 |

225 | 350 | − 5.00 | − 5.23 | 4.6 | − 4.69 | − 4.87 | 3.7 |

225 | 550 | − 6.27 | − 6.00 | − 4.2 | − 5.61 | − 5.77 | 2.9 |

225 | 750 | − 5.44 | − 5.22 | − 3.9 | − 4.67 | − 4.82 | 3.1 |

225 | 950 | − 2.58 | − 2.48 | − 3.9 | − 2.27 | − 2.33 | 2.4 |

375 | 150 | − 2.55 | − 2.49 | − 2.3 | − 2.54 | − 2.56 | 0.9 |

375 | 350 | − 5.28 | − 5.23 | − 1.0 | − 5.28 | − 5.42 | 2.5 |

375 | 550 | − 6.10 | − 6.00 | − 1.7 | − 6.41 | − 6.53 | 1.7 |

375 | 750 | − 5.14 | − 5.22 | 1.7 | − 5.30 | − 5.46 | 2.9 |

375 | 950 | − 2.60 | − 2.48 | − 4.6 | − 2.56 | − 2.60 | 1.7 |

525 | 150 | − 2.51 | − 2.49 | − 0.6 | − 2.87 | − 2.73 | − 5.1 |

525 | 350 | − 5.27 | − 5.23 | − 0.8 | − 6.13 | − 5.97 | − 2.7 |

525 | 550 | − 6.41 | − 6.00 | − 6.4 | − 7.59 | − 7.28 | − 4.0 |

525 | 750 | − 5.32 | − 5.22 | − 1.8 | − 6.20 | − 6.09 | − 1.7 |

525 | 950 | − 2.36 | − 2.48 | 5.2 | − 2.97 | − 2.88 | − 3.1 |

Appendix 6: The relative error of the estimated deformation for the plate with one clamped edge

Coordinate | Load case1 | Load case2 | |||||

|---|---|---|---|---|---|---|---|

x (mm) | y (mm) | Calculated values (mm) | Estimated values (mm) | Errors (%) | Calculated values (mm) | Estimated values (mm) | Errors (%) |

75 | 150 | − 0.21 | − 0.19 | − 9.5 | − 0.16 | − 0.16 | − 5.1 |

75 | 350 | − 1.11 | − 1.04 | − 6.3 | − 0.93 | − 0.90 | − 4.1 |

75 | 550 | − 2.60 | − 2.49 | − 4.2 | − 2.26 | − 2.19 | − 3.3 |

75 | 750 | − 4.49 | − 4.34 | − 3.3 | − 4.00 | − 3.90 | − 2.6 |

75 | 950 | − 6.62 | − 6.43 | − 2.9 | − 5.98 | − 5.85 | − 2.2 |

225 | 150 | − 0.24 | − 0.25 | 4.4 | − 0.22 | − 0.23 | 4.4 |

225 | 350 | − 1.17 | − 1.18 | 0.7 | − 1.11 | − 1.13 | 1.8 |

225 | 550 | − 2.66 | − 2.62 | − 1.5 | − 2.54 | − 2.53 | − 0.4 |

225 | 750 | − 4.55 | − 4.49 | − 1.3 | − 4.37 | − 4.32 | − 1.1 |

225 | 950 | − 6.68 | − 6.63 | − 0.7 | − 6.41 | − 6.37 | − 0.7 |

375 | 150 | − 0.24 | − 0.25 | 4.4 | − 0.25 | − 0.25 | 1.6 |

375 | 350 | − 1.17 | − 1.18 | 0.7 | − 1.22 | − 1.22 | − 0.1 |

375 | 550 | − 2.66 | − 2.62 | − 1.5 | − 2.76 | − 2.74 | − 0.7 |

375 | 750 | − 4.55 | − 4.49 | − 1.3 | − 4.68 | − 4.63 | − 1.0 |

375 | 950 | − 6.68 | − 6.63 | − 0.7 | − 6.82 | − 6.72 | − 1.5 |

525 | 150 | − 0.21 | − 0.19 | − 9.5 | − 0.26 | − 0.23 | − 9.9 |

525 | 350 | − 1.11 | − 1.04 | − 6.3 | − 1.29 | − 1.20 | − 7.1 |

525 | 550 | − 2.60 | − 2.49 | − 4.2 | − 2.94 | − 2.79 | − 5.0 |

525 | 750 | − 4.49 | − 4.34 | − 3.3 | − 4.99 | − 4.79 | − 4.1 |

525 | 950 | − 6.62 | − 6.43 | − 2.9 | − 7.26 | − 7.00 | − 3.6 |

Appendix 7: The relative error of the estimated deformation for the plate with two opposite simply supported edges

Coordinate | Load case1 | Load case2 | |||||

|---|---|---|---|---|---|---|---|

x (mm) | y (mm) | Calculated values (mm) | Estimated values (mm) | Errors (%) | Calculated values (mm) | Estimated values (mm) | Errors (%) |

75 | 150 | − 2.38 | − 2.28 | − 4.4 | − 2.16 | − 2.33 | 8.0 |

75 | 350 | − 5.24 | − 4.86 | − 7.2 | − 4.31 | − 4.61 | 6.9 |

75 | 550 | − 6.05 | − 5.53 | − 8.6 | − 5.10 | − 5.41 | 6.1 |

75 | 750 | − 5.37 | − 4.75 | − 11.5 | − 4.25 | − 4.48 | 5.3 |

75 | 950 | − 2.48 | − 2.26 | − 8.9 | − 2.08 | − 2.16 | 4.0 |

225 | 150 | − 2.47 | − 2.43 | − 1.9 | − 2.31 | − 2.36 | 2.4 |

225 | 350 | − 5.00 | − 5.22 | 4.5 | − 4.69 | − 4.77 | 1.7 |

225 | 550 | − 6.27 | − 6.44 | 2.8 | − 5.61 | − 5.67 | 1.1 |

225 | 750 | − 5.44 | − 5.22 | − 4.0 | − 4.67 | − 4.72 | 1.0 |

225 | 950 | − 2.58 | − 2.48 | − 4.1 | − 2.27 | − 2.30 | 0.9 |

375 | 150 | − 2.55 | − 2.43 | − 4.8 | − 2.54 | − 2.54 | 0.1 |

375 | 350 | − 5.28 | − 5.22 | − 1.0 | − 5.28 | − 5.31 | 0.6 |

375 | 550 | − 6.10 | − 6.34 | 3.9 | − 6.41 | − 6.48 | 1.0 |

375 | 750 | − 5.14 | − 5.18 | 1.0 | − 5.30 | − 5.35 | 0.8 |

375 | 950 | − 2.60 | − 2.52 | − 3.4 | − 2.56 | − 2.57 | 0.5 |

525 | 150 | − 2.51 | − 2.28 | − 9.1 | − 2.87 | − 2.78 | − 3.3 |

525 | 350 | − 5.27 | − 4.86 | − 7.8 | − 6.13 | − 6.07 | − 1.0 |

525 | 550 | − 6.41 | − 5.53 | − 13.7 | − 7.59 | − 7.61 | 0.3 |

525 | 750 | − 5.32 | − 4.75 | − 10.6 | − 6.20 | − 6.20 | 0.0 |

525 | 950 | − 2.36 | − 2.26 | − 4.3 | − 2.97 | − 2.93 | − 1.3 |

Appendix 8: The measured strain data at each measurement points

Point number | Coordinate | Strain data (με) | ||||

|---|---|---|---|---|---|---|

x (mm) | y (mm) | Case 1 | Case 2 | Case 3 | Case 4 | |

1 | 150 | 150 | 44 | 41 | 40 | 95 |

2 | 150 | 350 | 96 | 72 | 101 | 148 |

3 | 150 | 550 | 139 | 101 | 188 | 153 |

4 | 150 | 750 | 94 | 93 | 116 | 93 |

5 | 150 | 950 | 40 | 45 | 50 | 44 |

6 | 300 | 150 | 40 | 49 | 63 | 89 |

7 | 300 | 350 | 90 | 97 | 121 | 164 |

8 | 300 | 550 | 203 | 136 | 178 | 162 |

9 | 300 | 750 | 90 | 93 | 128 | 94 |

10 | 300 | 950 | 37 | 50 | 60 | 44 |

11 | 450 | 150 | 41 | 19 | 53 | 99 |

12 | 450 | 350 | 94 | 105 | 109 | 151 |

13 | 450 | 550 | 136 | 178 | 170 | 168 |

14 | 450 | 750 | 96 | 101 | 130 | 98 |

15 | 450 | 950 | 41 | 49 | 32 | 47 |

Appendix 9: The relative error of the estimated deformation of the tested plate for load cases 1 and 2

Coordinate | Load case1 | Load case2 | |||||

|---|---|---|---|---|---|---|---|

x (mm) | y (mm) | Measured values (mm) | Estimated values (mm) | Errors (%) | Measured values (mm) | Estimated values (mm) | Errors (%) |

75 | 150 | − 2.40 | − 2.53 | 5.7 | − 2.13 | − 1.92 | − 9.8 |

75 | 350 | − 5.56 | − 5.29 | − 4.9 | − 4.09 | − 3.70 | − 9.4 |

75 | 550 | − 6.60 | − 6.32 | − 4.2 | − 4.89 | − 4.45 | − 9.0 |

75 | 750 | − 5.63 | − 5.25 | − 6.8 | − 4.22 | − 3.86 | − 8.4 |

75 | 950 | − 2.55 | − 2.49 | − 2.5 | − 1.85 | − 1.94 | 4.6 |

225 | 150 | − 2.61 | − 2.51 | − 3.8 | − 2.21 | − 2.19 | − 1.0 |

225 | 350 | − 5.40 | − 5.25 | − 2.8 | − 4.74 | − 4.49 | − 5.2 |

225 | 550 | − 6.83 | − 6.28 | − 8.0 | − 5.65 | − 5.41 | − 4.2 |

225 | 750 | − 5.68 | − 5.23 | − 7.9 | − 4.86 | − 4.61 | − 5.1 |

225 | 950 | − 2.59 | − 2.48 | − 4.1 | − 2.36 | − 2.27 | − 4.0 |

375 | 150 | − 2.65 | − 2.48 | − 6.2 | − 2.67 | − 2.46 | − 7.7 |

375 | 350 | − 5.65 | − 5.21 | − 7.8 | − 5.41 | − 5.28 | − 2.4 |

375 | 550 | − 6.64 | − 6.25 | − 5.9 | − 6.81 | − 6.38 | − 6.3 |

375 | 750 | − 5.45 | − 5.21 | − 4.4 | − 5.56 | − 5.35 | − 3.8 |

375 | 950 | − 2.71 | − 2.48 | − 8.7 | − 2.53 | − 2.60 | 2.4 |

525 | 150 | − 2.26 | − 2.46 | 8.8 | − 3.01 | − 2.73 | − 9.4 |

525 | 350 | − 4.99 | − 5.17 | 3.7 | − 5.54 | − 6.07 | 9.6 |

525 | 550 | − 6.01 | − 6.22 | 3.5 | − 7.12 | − 7.35 | 3.1 |

525 | 750 | − 5.33 | − 5.19 | − 2.6 | − 6.11 | − 6.10 | − 0.2 |

525 | 950 | − 2.37 | − 2.47 | 4.1 | − 2.79 | − 2.92 | 4.7 |

Appendix 10: The relative error of the estimated deformation of the tested plate for load cases 3 and 4

Coordinate | Load case3 | Load case4 | |||||

|---|---|---|---|---|---|---|---|

x (mm) | y (mm) | Measured values (mm) | Estimated values (mm) | Errors (%) | Measured values (mm) | Estimated values (mm) | Errors (%) |

75 | 150 | − 2.77 | − 2.90 | 4.52 | − 3.17 | − 3.34 | 5.3 |

75 | 350 | − 6.69 | − 6.17 | − 7.82 | − 6.80 | − 6.50 | − 4.5 |

75 | 550 | − 7.60 | − 7.49 | − 1.40 | − 7.12 | − 7.26 | 2.0 |

75 | 750 | − 6.95 | − 6.33 | − 8.89 | − 5.42 | − 5.77 | 6.3 |

75 | 950 | − 2.88 | − 3.08 | 6.68 | − 2.72 | − 2.76 | 1.3 |

225 | 150 | − 3.23 | − 2.95 | − 8.64 | − 3.37 | − 3.43 | 1.7 |

225 | 350 | − 6.61 | − 6.18 | − 6.56 | − 6.46 | − 6.67 | 3.2 |

225 | 550 | − 7.45 | − 7.47 | 0.31 | − 7.85 | − 7.48 | − 4.7 |

225 | 750 | − 6.73 | − 6.30 | − 6.46 | − 6.24 | − 5.95 | − 4.7 |

225 | 950 | − 3.29 | − 3.02 | − 8.37 | − 2.78 | − 2.84 | 2.1 |

375 | 150 | − 3.19 | − 3.00 | − 6.01 | − 3.74 | − 3.51 | − 6.2 |

375 | 350 | − 6.59 | − 6.18 | − 6.12 | − 6.89 | − 6.85 | − 0.6 |

375 | 550 | − 7.70 | − 7.45 | − 3.19 | − 7.88 | − 7.69 | − 2.4 |

375 | 750 | − 6.51 | − 6.26 | − 3.80 | − 6.14 | − 6.13 | − 0.3 |

375 | 950 | − 3.24 | − 2.96 | − 8.81 | − 3.22 | − 2.92 | − 9.1 |

525 | 150 | − 3.34 | − 3.05 | − 8.77 | − 3.71 | − 3.59 | − 3.2 |

525 | 350 | − 6.33 | − 6.19 | − 2.16 | − 7.62 | − 7.02 | − 7.9 |

525 | 550 | − 7.41 | − 7.43 | 0.28 | − 7.70 | − 7.90 | 2.6 |

525 | 750 | − 5.80 | − 6.22 | 7.34 | − 6.91 | − 6.31 | − 8.7 |

525 | 950 | − 3.15 | − 2.90 | − 7.94 | − 2.89 | − 3.01 | 4.2 |

Appendix 11: The relative error of the estimated deformation of the tested plate for load cases 1 and 2

Coordinate | Load case1 | Load case2 | |||||

|---|---|---|---|---|---|---|---|

x (mm) | y (mm) | Measured values (mm) | Estimated values (mm) | Errors (%) | Measured values (mm) | Estimated values (mm) | Errors (%) |

75 | 150 | − 2.40 | − 2.31 | − 3.5 | − 2.13 | − 1.92 | − 9.7 |

75 | 350 | − 5.56 | − 5.10 | − 8.3 | − 4.09 | − 3.90 | − 4.6 |

75 | 550 | − 6.60 | − 5.57 | − 15.6 | − 4.89 | − 4.74 | − 3.0 |

75 | 750 | − 5.63 | − 4.66 | − 17.1 | − 4.22 | − 4.07 | − 3.4 |

75 | 950 | − 2.55 | − 2.26 | − 11.3 | − 1.85 | − 2.01 | 8.3 |

225 | 150 | − 2.61 | − 2.64 | 1.2 | − 2.21 | − 2.27 | 2.6 |

225 | 350 | − 5.40 | − 5.55 | 2.7 | − 4.74 | − 4.58 | − 3.4 |

225 | 550 | − 6.83 | − 6.85 | 0.4 | − 5.65 | − 5.49 | − 2.8 |

225 | 750 | − 5.68 | − 5.52 | − 2.8 | − 4.86 | − 4.62 | − 4.9 |

225 | 950 | − 2.59 | − 2.61 | 0.9 | − 2.36 | − 2.29 | − 3.1 |

375 | 150 | − 2.65 | − 2.62 | − 1.2 | − 2.67 | − 2.56 | − 3.8 |

375 | 350 | − 5.65 | − 5.51 | − 2.6 | − 5.41 | − 5.36 | − 0.9 |

375 | 550 | − 6.64 | − 6.82 | 2.7 | − 6.81 | − 6.51 | − 4.5 |

375 | 750 | − 5.45 | − 5.52 | 1.2 | − 5.56 | − 5.35 | − 3.8 |

375 | 950 | − 2.71 | − 2.60 | − 4.0 | − 2.53 | − 2.61 | 2.9 |

525 | 150 | − 2.26 | − 2.27 | 0.4 | − 3.01 | − 2.62 | − 13.0 |

525 | 350 | − 4.99 | − 4.63 | − 7.1 | − 5.54 | − 5.84 | 5.4 |

525 | 550 | − 6.01 | − 5.50 | − 8.4 | − 7.12 | − 7.34 | 3.0 |

525 | 750 | − 5.33 | − 4.64 | − 13.0 | − 6.11 | − 6.01 | − 1.6 |

525 | 950 | − 2.37 | − 2.26 | − 4.8 | − 2.79 | − 2.86 | 2.3 |

Appendix 12: The relative error of the estimated deformation of the tested plate for load cases 3 and 4

Coordinate | Load case3 | Load case4 | |||||

|---|---|---|---|---|---|---|---|

x (mm) | y (mm) | Measured values (mm) | Estimated values (mm) | Errors (%) | Measured values (mm) | Estimated values (mm) | Errors (%) |

75 | 150 | − 2.77 | − 2.85 | 2.8 | − 3.17 | − 3.39 | 6.7 |

75 | 350 | − 6.69 | − 5.95 | − 11.1 | − 6.80 | − 6.49 | − 4.6 |

75 | 550 | − 7.60 | − 7.30 | − 3.8 | − 7.12 | − 7.28 | 2.3 |

75 | 750 | − 6.95 | − 6.05 | − 13.0 | − 5.42 | − 5.79 | 6.8 |

75 | 950 | − 2.88 | − 2.83 | − 1.9 | − 2.72 | − 2.77 | 1.7 |

225 | 150 | − 3.23 | − 3.08 | − 4.6 | − 3.37 | − 3.50 | 3.8 |

225 | 350 | − 6.61 | − 6.36 | − 3.7 | − 6.46 | − 6.76 | 4.6 |

225 | 550 | − 7.45 | − 7.76 | 4.2 | − 7.85 | − 7.56 | − 3.6 |

225 | 750 | − 6.73 | − 6.45 | − 4.1 | − 6.24 | − 6.04 | − 3.2 |

225 | 950 | − 3.29 | − 3.15 | − 4.4 | − 2.78 | − 2.88 | 3.8 |

375 | 150 | − 3.19 | − 3.13 | − 2.0 | − 3.74 | − 3.64 | − 2.7 |

375 | 350 | − 6.59 | − 6.39 | − 3.0 | − 6.89 | − 7.13 | 3.5 |

375 | 550 | − 7.70 | − 7.72 | 0.3 | − 7.88 | − 8.08 | 2.5 |

375 | 750 | − 6.51 | − 6.44 | − 1.1 | − 6.14 | − 6.44 | 4.8 |

375 | 950 | − 3.24 | − 3.10 | − 4.2 | − 3.22 | − 3.06 | − 4.7 |

525 | 150 | − 3.34 | − 2.85 | − 14.7 | − 3.71 | − 3.54 | − 4.7 |

525 | 350 | − 6.33 | − 5.95 | − 6.0 | − 7.62 | − 6.80 | − 10.8 |

525 | 550 | − 7.41 | − 7.30 | − 1.5 | − 7.70 | − 7.68 | − 0.2 |

525 | 750 | − 5.80 | − 6.05 | 4.3 | − 6.91 | − 6.11 | − 11.6 |

525 | 950 | − 3.15 | − 2.83 | − 10.1 | − 2.89 | − 2.90 | 0.6 |

Appendix 13: The calculated strain (με) of the bridge deck

y (m) | x (m) | ||||

|---|---|---|---|---|---|

10.5 | 14.02 | 17.5 | 21.02 | 24.5 | |

0.5 | 7.63 | 13.24 | 13.04 | 13.24 | 7.63 |

1.5 | − 5.44 | 19.95 | 62.17 | 19.95 | − 5.44 |

2.475 | − 16.79 | 11.99 | 124.05 | 11.99 | − 16.79 |

3.275 | − 38.54 | − 22.01 | 141.56 | − 23.06 | − 38.54 |

4.74 | − 68.74 | − 159.42 | − 195.53 | − 157.82 | − 68.74 |

6.125 | − 77.62 | − 225.91 | − 1181.60 | − 222.76 | − 77.62 |

7.51 | − 68.74 | − 159.42 | − 195.53 | − 157.82 | − 68.74 |

8.975 | − 38.54 | − 22.01 | 141.56 | − 23.06 | − 38.54 |

9.775 | − 16.79 | 11.99 | 124.05 | 11.99 | − 16.79 |

10.75 | − 5.44 | 19.95 | 62.17 | 19.95 | − 5.44 |

11.75 | 7.63 | 13.24 | 13.04 | 13.24 | 7.63 |

Appendix 14: The relative error of the total deformation

Coordinate | Values calculated by FEM (mm) | Cubic polynomial strain function | Spline interpolation strain function | |||

|---|---|---|---|---|---|---|

x (m) | y (m) | Estimated values (mm) | Errors (%) | Estimated values (mm) | Errors (%) | |

10.5 | 0.00 | − 7.43 | − 6.41 | 13.80 | − 6.54 | 11.95 |

10.5 | 1.00 | − 9.72 | − 8.94 | 8.00 | − 9.04 | 6.99 |

10.5 | 2.00 | − 11.95 | − 11.28 | 5.61 | − 11.38 | 4.76 |

10.5 | 4.05 | − 15.90 | − 15.17 | 4.58 | − 15.33 | 3.57 |

10.5 | 4.74 | − 16.78 | − 16.03 | 4.46 | − 16.13 | 3.90 |

10.5 | 5.43 | − 17.33 | − 16.57 | 4.37 | − 16.69 | 3.71 |

10.5 | 6.13 | − 17.52 | − 16.81 | 4.03 | − 16.91 | 3.43 |

10.5 | 6.82 | − 17.33 | − 16.57 | 4.37 | − 16.80 | 3.07 |

10.5 | 7.51 | − 16.78 | − 16.03 | 4.46 | − 16.35 | 2.59 |

10.5 | 8.20 | − 15.90 | − 15.17 | 4.58 | − 15.29 | 3.82 |

10.5 | 10.25 | − 11.95 | − 11.28 | 5.61 | − 11.38 | 4.76 |

10.5 | 11.25 | − 9.72 | − 8.94 | 8.00 | − 9.04 | 6.99 |

10.5 | 12.25 | − 7.43 | − 6.41 | 13.80 | − 6.54 | 11.95 |

14.02 | 0.00 | − 5.04 | − 3.05 | 39.45 | − 4.32 | 14.29 |

14.02 | 1.00 | − 8.96 | − 7.42 | 17.18 | − 8.25 | 7.96 |

14.02 | 2.00 | − 12.96 | − 11.46 | 11.57 | − 12.12 | 6.47 |

14.02 | 4.05 | − 21.12 | − 20.20 | 4.34 | − 19.69 | 6.80 |

14.02 | 4.74 | − 23.30 | − 22.58 | 3.09 | − 21.64 | 7.12 |

14.02 | 5.43 | − 24.74 | − 24.18 | 2.27 | − 23.06 | 6.78 |

14.02 | 6.13 | − 25.25 | − 24.71 | 2.12 | − 23.60 | 6.52 |

14.02 | 6.82 | − 24.74 | − 24.18 | 2.27 | − 23.17 | 6.33 |

14.02 | 7.51 | − 23.30 | − 22.58 | 3.09 | − 21.86 | 6.17 |

14.02 | 8.20 | − 21.12 | − 20.20 | 4.34 | − 19.85 | 6.03 |

14.02 | 10.25 | − 12.96 | − 11.46 | 11.57 | − 12.12 | 6.47 |

14.02 | 11.25 | − 8.96 | − 7.42 | 17.18 | − 8.25 | 7.96 |

14.02 | 12.25 | − 5.04 | − 3.05 | 39.45 | − 4.32 | 14.29 |

17.5 | 0.00 | − 2.72 | − 3.67 | − 34.69 | − 3.76 | − 38.26 |

17.5 | 1.00 | − 7.51 | − 8.33 | − 10.90 | − 8.92 | − 18.77 |

17.5 | 2.00 | − 12.56 | − 13.66 | − 8.78 | − 13.73 | − 9.33 |

17.5 | 4.05 | − 25.49 | − 26.27 | − 3.09 | − 24.31 | 4.61 |

17.5 | 4.74 | − 30.13 | − 32.73 | − 8.64 | − 30.78 | − 2.18 |

17.5 | 5.43 | − 33.91 | − 36.61 | − 7.99 | − 36.94 | − 8.96 |

17.5 | 6.13 | − 35.94 | − 38.04 | − 5.84 | − 39.48 | − 9.85 |

17.5 | 6.82 | − 33.91 | − 36.61 | − 7.99 | − 37.05 | − 9.26 |

17.5 | 7.51 | − 30.13 | − 32.73 | − 8.64 | − 30.99 | − 2.86 |

17.5 | 8.20 | − 25.49 | − 26.27 | − 3.09 | − 24.16 | 5.22 |

17.5 | 10.25 | − 12.56 | − 13.66 | − 8.78 | − 13.73 | − 9.33 |

17.5 | 11.25 | − 7.51 | − 8.33 | − 10.90 | − 8.92 | − 18.77 |

17.5 | 12.25 | − 2.72 | − 3.67 | − 34.69 | − 3.76 | − 38.26 |

Appendix 15: The relative error of the local bending deformation

Coordinate | Values calculated by FEM (mm) | Cubic polynomial strain function | Spline interpolation strain function | |||

|---|---|---|---|---|---|---|

x (m) | y (m) | Estimated values (mm) | Errors (%) | Estimated values (mm) | Errors (%) | |

10.5 | 0.00 | 6.35 | 6.86 | − 7.93 | 6.72 | − 5.78 |

10.5 | 1.00 | 4.07 | 4.33 | − 6.31 | 4.23 | − 3.89 |

10.5 | 2.00 | 1.83 | 1.98 | − 8.17 | 1.88 | − 2.61 |

10.5 | 4.05 | − 2.12 | − 1.91 | 9.82 | − 2.07 | 2.21 |

10.5 | 4.74 | − 3.00 | − 2.77 | 7.58 | − 2.86 | 4.48 |

10.5 | 5.43 | − 3.54 | − 3.31 | 6.65 | − 3.42 | 3.42 |

10.5 | 6.13 | − 3.73 | − 3.55 | 4.95 | − 3.65 | 2.14 |

10.5 | 6.82 | − 3.54 | − 3.31 | 6.65 | − 3.53 | 0.30 |

10.5 | 7.51 | − 3.00 | − 2.77 | 7.58 | − 3.08 | − 2.88 |

10.5 | 8.20 | − 2.12 | − 1.91 | 9.82 | − 2.03 | 4.11 |

10.5 | 10.25 | 1.83 | 1.98 | − 8.17 | 1.88 | − 2.61 |

10.5 | 11.25 | 4.07 | 4.33 | − 6.31 | 4.23 | − 3.89 |

10.5 | 12.25 | 6.35 | 6.86 | − 7.93 | 6.72 | − 5.78 |

14.02 | 0.00 | 11.48 | 12.32 | − 7.36 | 11.05 | 3.70 |

14.02 | 1.00 | 7.56 | 7.96 | − 5.21 | 7.13 | 5.71 |

14.02 | 2.00 | 3.57 | 3.92 | − 9.89 | 3.26 | 8.59 |

14.02 | 4.05 | − 4.60 | − 4.83 | − 4.96 | − 4.31 | 6.33 |

14.02 | 4.74 | − 6.77 | − 7.20 | − 6.26 | − 6.26 | 7.59 |

14.02 | 5.43 | − 8.22 | − 8.80 | − 7.10 | − 7.68 | 6.46 |

14.02 | 6.13 | − 8.72 | − 9.33 | − 7.00 | − 8.22 | 5.74 |

14.02 | 6.82 | − 8.22 | − 8.80 | − 7.10 | − 7.80 | 5.11 |

14.02 | 7.51 | − 6.77 | − 7.20 | − 6.26 | − 6.48 | 4.33 |

14.02 | 8.20 | − 4.60 | − 4.83 | − 4.96 | − 4.47 | 2.79 |

14.02 | 10.25 | 3.57 | 3.92 | − 9.89 | 3.26 | 8.59 |

14.02 | 11.25 | 7.56 | 7.96 | − 5.21 | 7.13 | 5.71 |

14.02 | 12.25 | 11.48 | 12.32 | − 7.36 | 11.05 | 3.70 |

17.5 | 0.00 | 14.91 | 15.46 | − 3.66 | 15.36 | − 3.01 |

17.5 | 1.00 | 10.12 | 10.79 | − 6.63 | 10.20 | − 0.79 |

17.5 | 2.00 | 5.08 | 5.46 | − 7.63 | 5.39 | − 6.28 |

17.5 | 4.05 | − 7.85 | − 7.15 | 8.96 | − 5.18 | 33.96 |

17.5 | 4.74 | − 12.49 | − 13.61 | − 8.91 | − 11.66 | 6.68 |

17.5 | 5.43 | − 16.27 | − 17.49 | − 7.49 | − 17.82 | − 9.50 |

17.5 | 6.13 | − 18.31 | − 18.92 | − 3.33 | − 20.36 | − 11.19 |

17.5 | 6.82 | − 16.27 | − 17.49 | − 7.49 | − 17.92 | − 10.14 |

17.5 | 7.51 | − 12.49 | − 13.61 | − 8.91 | − 11.87 | 5.03 |

17.5 | 8.20 | − 7.85 | − 7.15 | 8.96 | − 5.03 | 35.93 |

17.5 | 10.25 | 5.08 | 5.46 | − 7.63 | 5.39 | − 6.28 |

17.5 | 11.25 | 10.12 | 10.79 | − 6.63 | 10.20 | − 0.79 |

17.5 | 12.25 | 14.91 | 15.46 | − 3.66 | 15.36 | − 3.01 |

Rights and permissions

About this article

Cite this article

Wang, Z., Duan, D., Yu, H. et al. Local bending deformation monitoring of bi-dimensional bridge deck based on the displacement–strain transfer matrix. J Civil Struct Health Monit 11, 809–832 (2021). https://doi.org/10.1007/s13349-021-00485-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13349-021-00485-w