Abstract

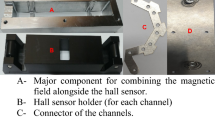

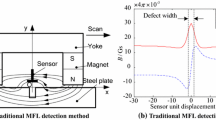

This paper describes the development of a magnetic sensor system for the evaluation of the condition of prestressed strands inside the bottom layer of concrete box beams. The sensor consists of an electromagnet which magnetizes embedded prestressing strand and measures the magnetic field response of the strands using Hall sensors embedded at different positions on the electromagnet. The novel aspect of this comprehensive system is the integration of measuring magnetic flux leakage (MFL) and main magnetic flux (MMF) signals. A computer-aided simulation model has also been developed to use these signals in estimating corrosion. The MFL signal gives indications of the presence of corrosion and cracks or fractures in the strands. The MMF signal quantifies the amount of steel loss in the strands due to corrosion or rusting. Both these techniques have been independently evaluated using magnetic inspection systems which made them suitable to be used in a single sensor system. This comprehensive system was evaluated in a laboratory setting to identify corrosion and strand breaks in prestressing strands. It was observed that the MFL signal could identify the presence of corrosion and strand breaks, while the MMF signal could be used to estimate the loss of steel due to corrosion. This system was also evaluated using it in an inspection of decommissioned prestressed box beams removed from Ohio’s oldest prestressed box-beam bridge. The findings from this inspection revealed a good match with the dissected areas of the box beams. Steps to move the system to implementation are also discussed. With further development improving the accuracy of this inspection system, it can become a valuable tool to bridge engineers for box-beam inspection.

Similar content being viewed by others

References

Ciolko AT, Tabatabai H (1999) Nondestructive methods for condition evaluation of prestressing steel strands in concrete bridges. Final report: phase I—technology review. National Cooperative Highway Research Program, Transportation Research Board, Washington

Jones L, Pessiki S, Naito C, Hodgson I (2010) Inspection methods and techniques to determine non visible corrosion of prestressing strands in concrete bridge components, Task 2—assessment of candidate NDT methods. ATLSS Report No. 09-09, Lehigh University, Bethlehem and Pennsylvania Department of Transportation, Harrisburg

Sugahara M, Kai Y, Tsukada K (2011) Nondestructive evaluation of bridge cables and strands using the magnetic main flux method. The 28th Annual International Bridge Conference, Pittsburgh, pp 339–346

Hillemeier B, Scheel H (2002) Non-Destructive location of prestressing steel fractures in post-tensioned and prestressed concrete. Transportation Research Board (TRB) Committee A2C03, Washington, pp 1–11

Rumiche F, Indacochea JE, Wang ML et al (2008) Detection and monitoring of corrosion in structural carbon steels using electromagnetic sensors. J Eng Mater Technol 130(3):031008

DaSilva M, Javidi S, Yakel A, Azizinamini A (2009) Nondestructive method to detect corrosion of steel elements in concrete. Final Report NDOR Research Project No. P597. National Bridge Research Organization, University of Nebraska-Lincoln and The Nebraska Department of Roads, Lincoln

Hillemeier B, Scheel H (1998) Magnetic detection of prestressing steel fractures in prestressed concrete. Mater Corros 49(11):799–804

Fernandes B, Wade JD, Nims DK, Devabhaktuni VK et al (2012) A new magnetic sensor concept for nondestructive evaluation of deteriorated prestressing strand. Res Nondestr Eval 23(1):46–68

Chen L, Que PW, Jin T (2005) A giant-magnetoresistance sensor for magnetic-flux-leakage nondestructive testing of a pipeline. Russ J Nondestr Test 41(7):462–465

Mihalache O, Preda G, Yusa N, Miya K (2000) Experimental Measurements and numerical simulation of OD and ID in plate ferromagnetic materials using magnetic flux leakage. Energy and Information in Non-Linear Systems. In: Proceeding of the 4th Japan-Europe Joint Workshop, Brno, Czech Republic, pp 106–109

Weischedel HR (2004) The magnetic flux leakage inspection of wire ropes. In: Nondestructive Testing Handbook, Electromagnetic Testing, 3rd edn, vol 4. American Society for Nondestructive Testing, Columbus, Ohio

Fernandes B, Nims DK, Devabhaktuni V (2012) Magnetic inspection of adjacent box-beam girders. In: Proceeding of 6th International Conference on Bridge Maintenance, Safety and Management (IABMAS 2012), Stresa, Italy, pp 2476–2481

Steinberg E, Miller R, Nims D, Sargand S (2011) Structural evaluation of LIC-310-0396 and FAY-35-17-6.82 box beams with advanced strand deterioration. ODOT Research and Development, Columbus Final Rep. FHWA/OH-2011/16

Fernandes B, Titus M, Nims D, Ghorbanpoor A, Devabhaktuni V et al (2012) Practical assessment of magnetic methods for corrosion detection in an adjacent precast, prestressed concrete box-beam bridge. Nondestruct Test Eval. doi:10.1080/10589759.2012.695785

Ghorbanpoor A (2000) Condition assessment of external P-T tendons in the Mid-Bay bridge, final report. Florida Department of Transportation, Tallahassee

Ghorbanpoor A, Borchelt R, Edwards M, Abdel Salam E (2000) Magnetic-based NDE of prestressed and post-tensioned Concrete members—the MFL system. Final report FHWA-RD-00-026. Federal Highway Administration, US Department of Transportation, McLean

Fernandes B, Nims D, Devabhaktuni V (2012) Computer aided modeling of magnetic behavior of embedded prestressing strand for corrosion estimation. J Nondestr Eval. doi:10.1007/s10921-012-0165-5

Rhim H, Büyüköztürk O (1998) Electromagnetic properties of concrete at microwave frequency range. ACI Mater J 95(3):262–271

Ohio Department of Transportation (2004) The third Ohio historic bridge inventory, evaluation, and management plan for bridges built 1951-1960 and the development of Ohio’s interstate highway system. Ohio Department of Transportation, Columbus

Lucas County Engineer (1958) Lucas County Bridge no. 1050 on Suder Ave. over Ottawa River—Washington Township. Lucas County Commissioners, Toledo

Naito C, Sause R, Hodgson I, Pessiki S, Desai C (2006) Forensic evaluation of prestressed box beams from the Lake view drive bridge over I-70. ATLSS, Bethlehem Final Rep.:06–13

Acknowledgments

The authors wish to thank the city of Toledo engineers—Ms. Kris Cousino and Mr. Rajiv Huria for permission to inspect the box beams. The authors are also thankful to Mr. Brian Geffe and Mr. Craig Schalk from Mosser Construction, Inc., for their help and assistance during the inspection on site.

Author information

Authors and Affiliations

Corresponding author

Glossary

- Magnetic flux leakage (MFL)

-

The leakage flux generated in a steel strand under magnetization at the location of fractures or corrosion

- Main magnetic flux (MMF)

-

The main flux generated in a steel strand under magnetization which flows through the entire core of the strand and electromagnet

- Remnant magnetic field (RMF)

-

The remnant flux that exists in the steel strand after it has been magnetically saturated and the external magnetic field is removed

Rights and permissions

About this article

Cite this article

Fernandes, B., Nims, D. & Devabhaktuni, V. Comprehensive MMF–MFL inspection for corrosion detection and estimation in embedded prestressing strands. J Civil Struct Health Monit 4, 43–55 (2014). https://doi.org/10.1007/s13349-013-0061-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13349-013-0061-4