Abstract

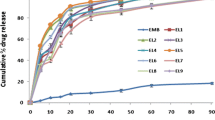

Developing amorphous solid dispersions with good flow properties is always challenging for formulation scientists to convert into tablets. Hence, the present study investigates the impact of the combination of melt-dispersion and surface-adsorption methods to prepare melt-dispersion granules with enhanced dissolution rate and flow properties. This study covers the formulation and pharmacokinetic study of fast-dissolving flurbiprofen tablets using PEG 6000 (hydrophilic carrier) and lactose (adsorbent). Response surface methodology (RSM) using the central composite design (CCD) was used to optimize independent variables like carrier concentrations and adsorbent concentrations, and their interactions with the dependent variables (responses), including solubility, angle of repose, Carr’s index, and cumulative % drug release, were investigated. The optimized formulation was selected based on the numerical optimization method and further investigated for FTIR spectroscopy, differential scanning calorimetry, and X-ray diffractometry. Then, the optimized formulation was compressed into tablets and evaluated for both in vitro dissolution and in vivo pharmacokinetics parameters. In vitro dissolution studies revealed that the prepared fast-dissolving tablets released the drug entirely within 15 min (Q15 of F4 tablets: 99.34 ± 1.24%), whereas conventional tablets took around 60 min for complete dissolution. Pharmacokinetic studies in rats revealed that fast-dissolving tablets showed 1.38-fold higher peak-plasma concentration (Cmax) and 1.39-fold higher bioavailability than conventional tablets. Overall, this study revealed the successful fabrication of fast-dissolving tablets via melt-dispersion paired with the surface-adsorption method to enhance the flow properties and the dissolution rate.

Graphical Abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Kaushik D, Dureja H, Saini TR. Mouth dissolving tablets: a review. Ind Drug. 2004;41:187–93.

Alzahrani A, Nyavanandi D, Repka M, et al. A systematic and robust assessment of hot-melt extrusion-based amorphous solid dispersions: theoretical prediction to practical implementation. Int J Pharm. 2022;23: 121951.

Mendonsa N, Almutairy B, Repka MA, et al. Manufacturing strategies to develop amorphous solid dispersions: an overview. J Drug Del Sci Tech. 2020;55: 101459.

Chella N, Tadikonda RR. Melt dispersion granules: formulation and evaluation to improve oral delivery of poorly soluble drugs-a case study with valsartan. Drug Del Ind Pharm. 2015;41:888–97.

Daravath B, Kumari GP. Improvement of bioavailability of poorly soluble racecadotril by solid dispersion with surface adsorption method: a case study. J Rep Pharm Sci. 2021;10(1):77–86.

Mohd AB, Vemula SK. Formulation and pharmacokinetics of vitamin E TPGS melt dispersion granules: an approach to improve oral delivery of flurbiprofen. J Bioequiv Availab. 2016;8:089–94.

Mahajan AN, Surti N, Patel P, et al. Melt dispersion adsorbed onto porous carriers: an effective method to enhance the dissolution and flow properties of raloxifene hydrochloride. ASSAY and Drug Dev Tech. 2020;18(6):282–94.

Sruti J, Patra CN, Swain S, et al. Improvement in the dissolution rate and tableting properties of cefuroxime axetil by melt-granulated dispersion and surface adsorption. Acta Pharm Sinica B. 2013;3:113–22.

Daravath B, Tadikonda RR, Vemula SK. Formulation and pharmacokinetics of gelucire solid dispersions of flurbiprofen. Drug Dev Ind Pharm. 2015;41:1254–62.

Vemula SK, Reddy SG. Formulation and pharmacokinetics of flurbiprofen sublimated fast dissolving tablets. Open Pharm Sci J. 2015;2(1).

Vemula SK, Veerareddy PR. Fast disintegrating tablets of flurbiprofen: formulation and characterization. Lat Am J Pharm. 2011;30:1135–41.

Mettu SR, P.R. Veerareddy PR. Formulation, evaluation and pharmacokinetics of flurbiprofen fast dissolving tablets. Brit J Pharm Res. 2013;3:617–31.

Mishra V, Thakur S, Patil A, Shukla A. Quality by design (QbD) approaches in current pharmaceutical set-up. Expert Opin Drug Deliv. 2018;15(8):737–58.

Myers RH, Montgomery DC, Anderson-Cook CM. Response surface methodology: process and product optimization using designed experiments. 3rd ed. ed: John Wiley & Sons, Inc.; 2009.

Daravath B, Naveen CH, Vemula SK, et al. Solubility and dissolution enhancement of flurbiprofen solid dispersion using hydrophilic carriers. Braz J Pharm Sci. 2017;53(4):1–10.

Sarabu S, Butreddy A, Repka MA, et al. Preliminary investigation of peroxide levels of Plasdone™ copovidones on the purity of atorvastatin calcium amorphous solid dispersions: impact of plasticizers on hot melt extrusion processability. J Drug Del Sci Tech. 2022;70: 103190.

Rao MR, Sonawane AS, Sapate SA, Mehta CH, Nayak U. Molecular modeling and in vitro studies to assess solubility enhancement of nevirapine by solid dispersion technique. J Mol Structure. 2023;5(1273): 134373.

Vemula SK. A novel approach to flurbiprofen pulsatile colonic release: formulation and pharmacokinetics of double-compression-coated mini-tablets. AAPS PharmSciTech. 2015;16(6):1465–73.

Vemula SK. Formulation and pharmacokinetics of colon-specific double-compression coated mini-tablets: chrono pharmaceutical delivery of ketorolac tromethamine. Int J Pharm. 2015;491:35–41.

Ebtesam WE, Ahmed AE, Nadia MM, et al. Optimization of gliclazide loaded alginate-gelatin beads employing central composite design. Drug Dev Ind Pharm. 2019;45(12):1959–72.

Gu B, Linehan B, Tseng Y-C. Optimization of the Büchi B-90 spray drying process using central composite design for preparation of solid dispersions. Int J Pharm. 2015;491(1–2):208–17.

Rakić T, Kasagić-Vujanović I, Jovanović M, et al. Comparison of full factorial design, central composite design, and Box-Behnken design in chromatographic method development for the determination of fluconazole and its impurities. Anal Lett. 2014;47(8):1334–47.

Taheri M, Bagheri M, Moazeni-Pourasil RS, et al. Response surface methodology based on central composite design accompanied by multivariate curve resolution to model gradient hydrophilic interaction liquid chromatography: prediction of separation for five major opium alkaloids. J Sep Sci. 2017;40(18):3602–11.

Zhao Y, Xie X, Zhao Y, Gao Y, et al. Effect of plasticizers on manufacturing ritonavir/copovidone solid dispersions via hot-melt extrusion: preformulation, physicochemical characterization, and pharmacokinetics in rats. Eur J Pharm Sci. 2019;127:60–70.

Genina N, Hadi B, Löbmann K. Hot melt extrusion as solvent free technique for a continuous manufacturing of drug-loaded mesoporous silica. J Pharm Sci. 2018;107:149–55.

Maha FE, Ahmed AE, Nadia MM, et al. Optimization of meloxicam solid dispersion formulations for dissolution enhancement and storage stability using 33 full factorial design based on response surface methodology. AAPS PharmSciTech. 2022;23(7):248.

Raja RS, Manisekar K. Experimental and statistical analysis on mechanical properties of nano fyash impregnated GFRP composites using central composite design method. Mat Design. 2016;89:884–92.

Mundada PK, Sawant KK, Mundada VP. Formulation and optimization of controlled release powder for reconstitution for metoprolol succinate multi unit particulate formulation using risk based QbD approach. J Drug Deliv Sci Technol. 2017;41:462–74.

Dordunoo SK, Ford JL, Rubinstein MH. Preformulation studies on solid dispersions containing triamterene or temazepam in polyethylene glycols or gelucire 44/14 for liquid filling of hard gelatin capsules. Drug Dev Ind Pharm. 1991;17:1685–93.

Acknowledgements

The authors acknowledge Karthikeya Drugs and Pharmaceuticals Private Limited, Kothapet, Hyderabad, for providing all required chemicals. The authors also acknowledge Jeeva Life Sciences, Uppal, Hyderabad, for giving permission and facilities for animal studies.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Formulation and evaluation were performed by Sateesh Kumar Vemula and Bhaskar Daravath. Sateesh Kumar Vemula wrote the first draft of the manuscript, and the final corrections were made under the supervision of Michael Repka. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Ethics approval

This study was performed in line with the principles of the Declaration of Helsinki. The in vivo bioavailability studies are approved by the institutional animal ethical committee (IAEC Approval No: CPCSEA/IAEC/JLS/006/02/17/006). All institutional and national guidelines for the care and use of laboratory animals were followed.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vemula, S.K., Daravath, B. & Repka, M. Quality by design (QbD) approach to develop fast-dissolving tablets using melt-dispersion paired with surface-adsorption method: formulation and pharmacokinetics of flurbiprofen melt-dispersion granules. Drug Deliv. and Transl. Res. 13, 3204–3222 (2023). https://doi.org/10.1007/s13346-023-01382-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13346-023-01382-z