Abstract

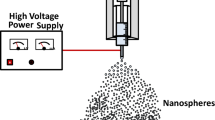

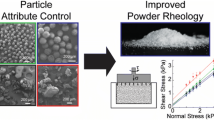

Electrohydrodynamic atomization (EHDA) is an emerging technique for the production of micron and nano-scaled particles. The process often involves Taylor cone enablement, which results in a fine spray yielding formulated droplets, which then undergo drying during deposition. In this work, novel multi-tip emitter (MTE) devices were designed, engineered and utilized for potential up-scaled EHDA, by comparison with a conventional single-needle system. To demonstrate this, the active ketoprofen (KETO) was formulated using polyvinylpyrrolidone (PVP) polymer as the matrix material. Here, PVP polymer (5% w/v) solution was prepared using ethanol and distilled water (80:20) as the vehicle. KETO was incorporated as 5% w/w of PVP. Physical properties of resulting solutions (viscosity, electrical conductivity, density and surface tension) were obtained. Formulations were electrosprayed through both single and novel MTEs under EHDA conditions at various flow rates (5–300 μl/min) and applied voltages (0–30 kV). The atomization process using MTEs and single nozzle was monitored at using various process parameters via a digital optical camera. Resulting particles were collected 200 mm below processing heads and were analyzed using differential scanning calorimetry (DSC), thermal gravimetric analysis (TGA), X-ray diffraction (XRD) and scanning electron microscopy (SEM). Digital recordings confirmed stable MTE jetting at higher flow rates. Electron micrographs confirmed particle size variation arising due to nozzle head design and evidenced stable jetting derived greater near-uniform particles. DSC, XRD and TGA confirm KETO molecules were encapsulated and dispersed into PVP polymer particles. In conclusion, novel MTE devices enabled stable atomization even at higher flow rates when compared to conventional single-needle device. This indicates an exciting approach for scaling up (EHDA) in contrast to current efforts focusing on multiple-nozzle and pore-based processing outlets.

Similar content being viewed by others

References

Mehta P, Haj-Ahmad R, Rasekh M, Arshad MS, Smith A, van der Merwe SM, et al. Pharmaceutical and biomaterial engineering via electrohydrodynamic atomization technologies. Drug Discov Today. 2017;22:157–65.

Jaworek A. Micro- and nanoparticle production by electrospraying. Powder Technol 2007 7/10;176(1):18–35.

Jafari-Nodoushan M, Mobedi H, Barzin J. Encapsulation via electrohydrodynamic atomization spray technology (electrospraying). In: Munaya Mishra, editor. Handbook of encapsulation and controlled release: CRS press; 2016. p. 411–437.

Bocanegra R, Galán D, Márquez M, Loscertales IG, Barrero A. Multiple electrosprays emitted from an array of holes. J Aerosol Sci 2005 12;36(12):1387–1399.

Rulison AJ, Flagan RC. Scale-up of electrospray atomization using linear arrays of Taylor cones. Rev Sci Instrum. 1993;64(3):683–6.

Almekinders J, Jones C. Multiple jet electrohydrodynamic spraying and applications. J Aerosol Sci. 1999;30(7):969–71.

Yang Y, Jia Z, Li Q, Hou L, Liu J, Wang L, et al. A shield ring enhanced equilateral hexagon distributed multi-needle electrospinning spinneret. IEEE Trans Dielectr Electr Insul. 2010 OCT;17(5):1592–601.

Jafari-Nodoushan M, Barzin J, Mobedi H. Size and morphology controlling of PLGA microparticles produced by electro hydrodynamic atomization. Polym Adv Technol. 2015;26(5):502–13.

David P, Smith H. The Electrohydrodynamic Atomization of Liquids 1986;IA-22(3):527–535. https://doi.org/10.1109/TIA.1986.4504754.

Zhang L, Huang J, Si T, Xu RX. Coaxial electrospray of microparticles and nanoparticles for biomedical applications. Expert Rev Med Devices. 2012 NOV;9(6):595–612.

Haj-Ahmad R, Rasekh M, Nazari K, Li Y, Fu Y, Li B, et al. EHDA spraying: a multi-material nano-engineering route. Curr Pharm Des. 2015;21(22):3239–47.

Zhang C, Chang M, Ahmad Z, Hu W, Zhao D, Li J. Stable single device multi-pore electrospraying of polymeric microparticles via controlled electrostatic interactions. RSC Adv. 2015;5(107):87919–23.

Taylor G 1964 Disintegration of water drops in an electric field. Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences: The Royal Society.

Taylor G 1969Electrically driven jets. Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences: The Royal Society.

Reneker DH, Yarin AL. Electrospinning jets and polymer nanofibers. Polymer. 2008;49(10):2387–425.

Hohman MM, Shin M, Rutledge G, Brenner MP. Electrospinning and electrically forced jets. I. Stability theory. Phys Fluids. 2001;13(8):2201–20.

Yu D, Williams G, Wang X, Yang J, Li X, Qian W, et al. Polymer-based nanoparticulate solid dispersions prepared by a modified electrospraying process. J Biomed Sci Eng. 2011;4:741–9.

Bohr A, Kristensen J, Dyas M, Edirisinghe M, Stride E. Release profile and characteristics of electrosprayed particles for oral delivery of a practically insoluble drug. J R Soc Interface. 2012;9(75):2437–49.

Jahangiri A, Barzegar-Jalali M, Garjani A, Javadzadeh Y, Hamishehkar H, Rameshrad M, et al. Physicochemical characterization and pharmacological evaluation of ezetimibe-PVP K30 solid dispersions in hyperlipidemic rats. Colloids Surf B: Biointerfaces 2015 10/1. 2015;134:423–30.

Leuner C, Dressman J. Improving drug solubility for oral delivery using solid dispersions. European J Pharm Biopharm 2000 7/3;50(1):47–60.

Illangakoon UE, Gill H, Shearman GC, Parhizkar M, Mahalingam S, Chatterton NP, et al. Fast dissolving paracetamol/caffeine nanofibers prepared by electrospinning. Int J Pharm 2014 12/30;477(1–2):369–379.

Adibkia K, Barzegar-Jalali M, Maheri-Esfanjani H, Ghanbarzadeh S, Shokri J, Sabzevari A, et al. Physicochemical characterization of naproxen solid dispersions prepared via spray drying technology. Powder Technol 2013 9. 246:448–55.

Payab S, Davaran S, Tanhaei A, Fayyazi B, Jahangiri A, Farzaneh A, et al. Triamcinolone acetonide-Eudragit® RS100 nanofibers and nanobeads: morphological and physicochemical characterization. Artif Cell Nanomed Biotechnol. 2016;44(1):362–9.

Nazari K, Kontogiannidou E, Ahmad RH, Gratsani A, Rasekh M, Arshad MS, et al. Development and characterisation of cellulose based electrospun mats for buccal delivery of non-steroidal anti-inflammatory drug (NSAID). Eur J Pharm Sci. 2017;102:147–55.

Sethia S, Squillante E. Solid dispersion of carbamazepine in PVP K30 by conventional solvent evaporation and supercritical methods. Int J Pharm. 2004;272(1–2):1–10.

Van den Mooter G, Wuyts M, Blaton N, Busson R, Grobet P, Augustijns P, et al. Physical stabilisation of amorphous ketoconazole in solid dispersions with polyvinylpyrrolidone K25. Eur J Pharm Sci 2001 1;12(3):261–269.

Hancock BC, Carlson GT, Ladipo DD, Langdon BA, Mullarney MP. Comparison of the mechanical properties of the crystalline and amorphous forms of a drug substance. Int J Pharm. 2002;241(1):73–85.

Hancock BC, Zografi G. Characteristics and significance of the amorphous state in pharmaceutical systems. J Pharm Sci. 1997;86(1):1–12.

Elamin A, Ahlneck C, Alderborn G, Nystrom C. Increased metastable solubility of milled griseofulvin, depending on the formation of a disordered surface structure. Int J Pharm. 1994;111(2):159–70.

Hancock B, Parks M. What is the true solubility advantage for amorphous pharmaceuticals? Pharm Res. 2000 APR;17(4):397–404.

Graeser KA, Patterson JE, Rades T. Applying thermodynamic and kinetic parameters to predict the physical stability of two differently prepared amorphous forms of simvastatin. Curr Drug Deliv. 2009;6(4):374–82.

Craig D, Royall P, Kett V, Hopton M. The relevance of the amorphous state to pharmaceutical dosage forms: glassy drugs and freeze dried systems. Int J Pharm. 1999;179(2):179–207.

Songsurang K, Praphairaksit N, Siraleartmukul K, Muangsin N. Electrospray fabrication of doxorubicin-chitosan-tripolyphosphate nanoparticles for delivery of doxorubicin. Arch Pharm Res. 2011 APR;34(4):583–92.

Manna L, Banchero M, Sola D, Ferri A, Ronchetti S, Sicardi S. Impregnation of PVP microparticles with ketoprofen in the presence of supercritical CO2. J Supercrit Fluids 2007 10;42(3):378–384.

Mura P, Moyano J, Gonzalez-Rodriguez M, Rabasco-Alvarez A, Cirri M, Maestrelli F. Characterization and dissolution properties of ketoprofen in binary and ternary solid dispersions with polyethylene glycol and surfactants. Drug Dev Ind Pharm. 2005;31(4–5):425–34.

Di Martino P, Joiris E, Gobetto R, Masic A, Palmieri GF, Martelli S. Ketoprofen-poly(vinylpyrrolidone) physical interaction. J Cryst Growth. 2004;265(1–2):302–8.

Acknowledgements

The authors would like to thank the EPSRC EHDA Network and The Royal Society (Industrial Fellowship) for their support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Haj-Ahmad, R., Rasekh, M., Nazari, K. et al. Stable increased formulation atomization using a multi-tip nozzle device. Drug Deliv. and Transl. Res. 8, 1815–1827 (2018). https://doi.org/10.1007/s13346-018-0518-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13346-018-0518-4