Abstract

Process control and optimization is a critical aspect of process analytical technology (PAT), quality by design (QbD), and the implementation of continuous manufacturing procedures. While process control and optimization techniques have been utilized in other manufacturing industries for decades, the pharmaceutical industry has only recently begun to adopt these procedures. Micronization, particularly milling, is a generally low-yield, high-energy consumption process that is well suited for a process optimization mindset. This review discusses optimization of the pharmaceutical milling process through design space development, theoretical and empirical modeling, and monitoring of critical quality attributes.

Similar content being viewed by others

References

Del Castillo E. Process optimization: a statistical approach. Vol Book, Whole. New York: Springer; 2007, https://doi.org/10.1007/978-0-387-71435-6.

FDA. Guidance for Industry PAT: a framework for innovative pharmaceutical development, manufacuring, and quality assurance. FDA official document. 2004:16. http://www.fda.gov/CDER/guidance/6419fnl.pdf.

International Conference on Harmonisation Expert Working G. Pharmaceutical development Q8(R2). ICH Harmonised Tripartite Guideline. 2009;1–24.

International Conference on Harmonisation Expert Working G. Pharmaceutical quality system Q10. ICH Harmonised Tripartite Guideline. 2008;177–81. doi:EMEA/CHMP/ICH/214732/2007.

International Conference on Harmonisation Expert Working G. Quality risk management Q9. ICH Harmonised Tripartite Guideline. 2005; 1–23. https://doi.org/10.1007/s11095-007-9511-1.

Yu LX, et al. Pharm Res. 2008;25(4):781–91. https://doi.org/10.1007/s11095-007-9511-1.

LX Y, Amidon G, Khan MA, Hoag SW, Polli J, Raju GK, et al. Understanding pharmaceutical quality by design. AAPS J. 2014;16(4):771–83. https://doi.org/10.1208/s12248-014-9598-3.

Levin M, Levin M. Pharmaceutical process scale-up. UNKNOWN:Informa Healthcare: New York; 2005.

Myerson AS, Krumme M, Nasr M, Thomas H, Braatz RD. Control systems engineering in continuous pharmaceutical manufacturing May 20–21, 2014 continuous manufacturing symposium. J Pharm Sci. 2015;104(3):832–9. https://doi.org/10.1002/jps.24311.

Chaumeil JC. Micronization: a method of improving the bioavailability of poorly soluble drugs. Methods Find Exp Clin Pharmacol. 1998;20(3):211–5.

Williams RO, Watts AB, Miller DA. Formulating poorly water soluble drugs. 1st ed., Vol Book, Whole. New York, AAPS Press; 2012. https://doi.org/10.1007/978-1-4614-1144-4.

Noyes AA, Whitney WR. The rate of solution of solid substances in their own solutions. J Am Chem Soc. 1897;19(12):930–4. https://doi.org/10.1021/ja02086a003.

Bhakay A, Merwade M, Bilgili E, Dave RN. Novel aspects of wet milling for the production of microsuspensions and nanosuspensions of poorly water-soluble drugs. Drug Dev Ind Pharm. 2011;37(8):963–76. https://doi.org/10.3109/03639045.2010.551775.

Hickey AJ, Martonen TB, Yang Y. Theoretical relationship of lung deposition to the fine particle fraction of inhalation aerosols. Pharm Acta Helv. 1996;71(3):185–90. https://doi.org/10.1016/0031-6865(96)00014-3.

Yang MY, Chan JGY, Chan H-K. Pulmonary drug delivery by powder aerosols. J Control Release. 2014;193:228–40. https://doi.org/10.1016/j.jconrel.2014.04.055.

Patton JS, Byron PR. Inhaling medicines: delivering drugs to the body through the lungs. Nat Rev Drug Discov. 2007;6(1):67–74. https://doi.org/10.1038/nrd2153.

Yalkowsky SH, Bolton S. Particle size and content uniformity. Pharm Res. 1990;7(9):962–6. https://doi.org/10.1023/a:1015958209643.

Huang C-Y, Sherry KM. Prediction of drug particle size and content uniformity in low-dose solid dosage forms. Int J Pharm. 2010;383(1):70–80. https://doi.org/10.1016/j.ijpharm.2009.09.009.

Clement S, Purutyan H. Narrowing down equipment choices for particle-size reduction. Chem Eng Prog. 2002;98:50–4.

Parrott EL. Milling of pharmaceutical solids. J Pharm Sci. 1974;63(6):813–29. https://doi.org/10.1002/jps.2600630603.

Rumpf H. Physical aspects of comminution and new formulation of a law of comminution. Powder Technol. 1973;7(3):145–59. https://doi.org/10.1016/0032-5910(73)80021-X.

Fatah N. Study and comparison of micronic and nanometric powders: analysis of physical, flow and interparticle properties of powders. Powder Technol. 2009;190(1-2):41–7. https://doi.org/10.1016/j.powtec.2008.04.055.

Hickey AJ, Mansour HM, Telko MJ, Xu Z, Smyth HDC, Mulder T, et al. Physical characterization of component particles included in dry powder inhalers. I. Strategy review and static characteristics. J Pharm Sci. 2007;96(5):1282–301. https://doi.org/10.1002/jps.20916.

Hickey AJ, Mansour HM, Telko MJ, Xu Z, Smyth HDC, Mulder T, et al. Physical characterization of component particles included in dry powder inhalers. II. Dynamic characteristics. J Pharm Sci. 2007;96(5):1302–19. https://doi.org/10.1002/jps.20943.

Fisher ES. Milling of active pharmaceutical ingredients. Encyclopedia of pharmaceutical technology, 3rd Edition. Taylor & Francis Online; 2013. p. 2339–51.

Vogel L, Peukert W. Breakage behaviour of different materials—construction of a mastercurve for the breakage probability. Powder Technol. 2003;129(1):101–10. https://doi.org/10.1016/S0032-5910(02)00217-6.

Yokoyama T, Inoue Y. Chapter 10 Selection of fine grinding mills. Handbook of powder technology. 2007; 12:487–508. https://doi.org/10.1016/S0167-3785(07)12013-3.

Rasenack N, Müller BW. Micron-size drug particles: common and novel micronization techniques. Pharm Dev Technol. 2004;9(1):1–13. https://doi.org/10.1081/PDT-120027417.

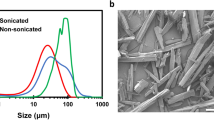

Saleem IY, Smyth HDC. Micronization of a soft material: air-jet and micro-ball milling. AAPS PharmSciTech. 2010;11(4):1642–9. https://doi.org/10.1208/s12249-010-9542-5.

Vatsaraj NB, Gao D, Kowalski DL. Optimization of the operating conditions of a lab scale Aljet mill using lactose and sucrose: a technical note. AAPS PharmSciTech. 2003;4(2):141–6. https://doi.org/10.1208/pt040227.

Chamayou A, Dodds JA. Chapter 8 Air jet milling. Handbook of powder technology 2007;12:421–35. https://doi.org/10.1016/S0167-3785(07)12011-X.

Teng S, Wang P, Zhu L, Young MW, Gogos CG. Experimental and numerical analysis of a lab-scale fluid energy mill. Powder Technol. 2009;195(1):31–9. https://doi.org/10.1016/j.powtec.2009.05.013.

Peltonen L, Hirvonen J. Pharmaceutical nanocrystals by nanomilling: critical process parameters, particle fracturing and stabilization methods. J Pharm Pharmacol. 2010;62(11):1569–79. https://doi.org/10.1111/j.2042-7158.2010.01022.x.

Singh SK, Srinivasan KK, Gowthamarajan K, Singare DS, Prakash D, Gaikwad NB. Investigation of preparation parameters of nanosuspension by top-down media milling to improve the dissolution of poorly water-soluble glyburide. Eur J Pharm Biopharm. 2011;78(3):441–6. https://doi.org/10.1016/j.ejpb.2011.03.014.

Tavares LM. Chapter 1 Breakage of single particles: quasi-static. In: Agba D, Salman MG, Michael JH, editors. Handbook of powder technology. Amsterdam: Elsevier Science B.V.; 2007. p. 3–68.

Tavares LM, King RP. Single-particle fracture under impact loading. Int J Miner Process. 1998;54(1):1–28. https://doi.org/10.1016/S0301-7516(98)00005-2.

Chau KT, Wu S. Chapter 2 Impact breakage of single particles: double impact test. In: Agba D, Salman MG, Michael JH, editors. Handbook of powder technology. Amsterdam: Elsevier Science B.V.; 2007. p. 69–85.

Ghadiri M, Kwan CC, Ding Y. Chapter 14 Analysis of milling and the role of feed properties. In: Agba D, Salman MG, Michael JH, editors. Handbook of powder technology. Amsterdam: Elsevier Science B.V.; 2007. p. 605–34.

Weerasekara NS, Powell MS, Cleary PW, Tavares LM, Evertsson M, Morrison RD, et al. The contribution of DEM to the science of comminution. Powder Technol. 2013;248:3–4. https://doi.org/10.1016/j.powtec.2013.05.032.

Kanda Y, Sano S, Yashima S. A consideration of grinding limit based on fracture mechanics. Powder Technol. 1986;48(3):263–7. https://doi.org/10.1016/0032-5910(86)80051-1.

Annapragada A, Adjei A. Numerical simulation of milling processes as an aid to process design. Int J Pharm. 1996;136(1-2):1–11. https://doi.org/10.1016/0378-5173(96)04465-1.

Ghadiri M, Zhang Z. Impact attrition of particulate solids. Part 1: a theoretical model of chipping. Chem Eng Sci. 2002;57(17):3659–69. https://doi.org/10.1016/S0009-2509(02)00240-3.

Kwan CC, Chen YQ, Ding YL, Papadopoulos DG, Bentham AC, Ghadiri M. Development of a novel approach towards predicting the milling behaviour of pharmaceutical powders. Eur J Pharm Sci. 2004;23(4-5):327–36. https://doi.org/10.1016/j.ejps.2004.08.006.

García-Muñoz S, Dolph S, Ward HW. Handling uncertainty in the establishment of a design space for the manufacture of a pharmaceutical product. Comput Chem Eng. 2010;34(7):1098–107. https://doi.org/10.1016/j.compchemeng.2010.02.027.

Lepore J, Spavins J. PQLI design space. J Pharm Innov. 2008;3(2):79–87. https://doi.org/10.1007/s12247-008-9034-2.

Boukouvala F, Muzzio FJ, Ierapetritou MG. Design space of pharmaceutical processes using data-driven-based methods. J Pharm Innov. 2010;5(3):119–37. https://doi.org/10.1007/s12247-010-9086-y.

Rantanen J, Khinast J. The future of pharmaceutical manufacturing sciences. J Pharm Sci. 2015;104(11):3612–38. https://doi.org/10.1002/jps.24594.

Yazdi AK, Smyth HDC. Implementation of design of experiments approach for the micronization of a drug with a high brittle–ductile transition particle diameter. Drug Dev Ind Pharm. 2017;43(3):364–71. https://doi.org/10.1080/03639045.2016.1253727.

Midoux N, Hošek P, Pailleres L, Authelin J. Micronization of pharmaceutical substances in a spiral jet mill. Powder Technol. 1999;104(2):113–20. https://doi.org/10.1016/S0032-5910(99)00052-2.

Cho H, Kwon J, Kim K, Mun M. Optimum choice of the make-up ball sizes for maximum throughput in tumbling ball mills. Powder Technol. 2013;246:625–34. https://doi.org/10.1016/j.powtec.2013.06.026.

Rittinger PRv. Lehrbuch der Aufbereitungskunde in ihrer neuesten Entwicklung und Ausbindung systematisch dargestellt. vol Book, Whole. Germany; 1867.

Austin LG. A commentary on the Kick, Bond and Rittinger laws of grinding. Powder Technol. 1973;7(6):315–7. https://doi.org/10.1016/0032-5910(73)80042-7.

Bond FC. The third theory of communition. Trans Metall Soc AIME. 1952;193:484–94.

Chen Y, Ding Y, Papadopoulos DG, Ghadiri M. Energy-based analysis of milling alpha-lactose monohydrate. J Pharm Sci. 2004;93(4):886–95. https://doi.org/10.1002/jps.10568.

Austin LG, Bhatia VK. Experimental methods for grinding studies in laboratory mills. Powder Technol. 1972;5(5):261–6. https://doi.org/10.1016/0032-5910(72)80029-9.

Austin LG. Introduction to the mathematical description of grinding as a rate process. Powder Technol. 1971;5(1):1–17. https://doi.org/10.1016/0032-5910(71)80064-5.

Capece M, Dave R, Bilgili E. A rational function approximation to the effectiveness factor for multi-particle interactions in dense-phase dry milling. Powder Technol. 2012;230:67–76. https://doi.org/10.1016/j.powtec.2012.06.054.

Capece M, Bilgili E, Dave RN. Emergence of falsified kinetics as a consequence of multi-particle interactions in dense-phase comminution processes. Chem Eng Sci. 2011;66(22):5672–83. https://doi.org/10.1016/j.ces.2011.08.001.

Austin LG, Bagga P. An analysis of fine dry grinding in ball mills. Powder Technol. 1981;28(1):83–90. https://doi.org/10.1016/0032-5910(81)87014-3.

Gutsche O, Fuerstenau DW. Fracture kinetics of particle bed comminution—ramifications for fines production and mill optimization. Powder Technol. 1999;105(1):113–8. https://doi.org/10.1016/S0032-5910(99)00125-4.

Bilgili E, Yepes J, Scarlett B. Formulation of a non-linear framework for population balance modeling of batch grinding: beyond first-order kinetics. Chem Eng Sci. 2006;61(1):33–44. https://doi.org/10.1016/j.ces.2004.11.060.

Capece M, Bilgili E, Dave R. Identification of the breakage rate and distribution parameters in a non-linear population balance model for batch milling. Powder Technol. 2011;208(1):195–204. https://doi.org/10.1016/j.powtec.2010.12.019.

Ketterhagen WR, am Ende MT, Hancock BC. Process modeling in the pharmaceutical industry using the discrete element method. J Pharm Sci. 2009;98(2):442–70. https://doi.org/10.1002/jps.21466.

Brosh T, Kalman H, Levy A, Peyron I, Ricard F. DEM–CFD simulation of particle comminution in jet-mill. Powder Technol. 2014;257:104–12. https://doi.org/10.1016/j.powtec.2014.02.043.

Afolabi A, Akinlabi O, Bilgili E. Impact of process parameters on the breakage kinetics of poorly water-soluble drugs during wet stirred media milling: a microhydrodynamic view. Eur J Pharm Sci. 2014;51:75–86. https://doi.org/10.1016/j.ejps.2013.09.002.

Burgess DJ, Duffy E, Etzler F, Hickey AJ. Particle size analysis: AAPS workshop report, cosponsored by the Food and Drug Administration and the United States Pharmacopeia. AAPS J. 2004;6:e20. https://doi.org/10.1208/aapsj060320.

Yu W, Muteki K, Zhang L, Kim G. Prediction of bulk powder flow performance using comprehensive particle size and particle shape distributions. J Pharm Sci. 2011;100(1):284–93. https://doi.org/10.1002/jps.22254.

Ward G, Schultz R. Process-induced crystallinity changes in albuterol sulfate and its effect on powder physical stability. Pharm Res. 1995;12(5):773–779.

Huttenrauch R, Fricke S, Zielke P. Mechanical activation of pharmaceutical systems. Pharm Res. 1985;2(6):302–6. https://doi.org/10.1023/A:1016397719020.

Saleki-Gerhardt A, Ahlneck C, Zografi G. Assessment of disorder in crystalline solids. Int J Pharm. 1994;101(3):237–47. https://doi.org/10.1016/0378-5173(94)90219-4.

Chamarthy SP, Pinal R. The nature of crystal disorder in milled pharmaceutical materials. Colloids Surf A Physicochem Eng Asp. 2008;331(1):68–75. https://doi.org/10.1016/j.colsurfa.2008.06.040.

Chikhalia V, Forbes RT, Storey RA, Ticehurst M. The effect of crystal morphology and mill type on milling induced crystal disorder. Eur J Pharm Sci. 2006;27(1):19–26. https://doi.org/10.1016/j.ejps.2005.08.013.

Silva AFT, Burggraeve A, Denon Q, Van Der Meeren P, Sandler N, Van Den Kerkhof T, et al. Particle sizing measurements in pharmaceutical applications: comparison of in-process methods versus off-line methods. Eur J Pharm Biopharm. 2013;85(3):1006–18. https://doi.org/10.1016/j.ejpb.2013.03.032.

Kumar V, Taylor MK, Mehrotra A, Stagner WC. Real-time particle size analysis using focused beam reflectance measurement as a process analytical technology tool for a continuous granulation–drying–milling process. AAPS PharmSciTech. 2013;14(2):523–30. https://doi.org/10.1208/s12249-013-9934-4.

De Beer T, Burggraeve A, Fonteyne M, Saerens L, Remon JP, Vervaet C. Near infrared and Raman spectroscopy for the in-process monitoring of pharmaceutical production processes. Int J Pharm. 2011;417(1-2):32–47. https://doi.org/10.1016/j.ijpharm.2010.12.012.

Gamble JF, Tobyn M, Hamey R. Application of image-based particle size and shape characterization systems in the development of small molecule pharmaceuticals. J Pharm Sci. 2015;104(5):1563–74. https://doi.org/10.1002/jps.24382.

Nalluri VR, Schirg P, Gao X, Virdis A, Imanidis G, Kuentz M. Different modes of dynamic image analysis in monitoring of pharmaceutical dry milling process. Int J Pharm. 2010;391(1–2):107–14. https://doi.org/10.1016/j.ijpharm.2010.02.027.

Inam MA, Ouattara S, Frances C. Effects of concentration of dispersions on particle sizing during production of fine particles in wet grinding process. Powder Technol. 2011;208(2):329–36. https://doi.org/10.1016/j.powtec.2010.08.025.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author (HDCS) of this paper consults for and has equity ownership in Respira Therapeutics and Nob Hill Therapeutics on inhaled product development. The terms of this arrangement have been reviewed and approved by the University of Texas at Austin in accordance with its policy on objectivity in research.

Rights and permissions

About this article

Cite this article

Brunaugh, A., Smyth, H.D.C. Process optimization and particle engineering of micronized drug powders via milling. Drug Deliv. and Transl. Res. 8, 1740–1750 (2018). https://doi.org/10.1007/s13346-017-0444-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13346-017-0444-x