Abstract

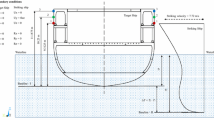

The crashworthiness of the cargo containment systems (CCSs) of a floating liquid natural gas (FLNG) and the side structures in side-by-side offloading operations scenario are studied in this paper. An FLNG vessel is exposed to potential threats from collisions with a liquid natural gas carrier (LNGC) during the offloading operations, which has been confirmed by a model test of FLNG-LNGC side-by-side offloading operations. A nonlinear finite element code LS-DYNA is used to simulate the collision scenarios during the offloading operations. Finite element models of an FLNG vessel and an LNGC are established for the purpose of this study, including a detailed LNG cargo containment system in the FLNG side model. Based on the parameters obtained from the model test and potential dangerous accidents, typical collision scenarios are defined to conduct a comprehensive study. To evaluate the safety of the FLNG vessel, a limit state is proposed based on the structural responses of the LNG CCS. The different characteristics of the structural responses for the primary structural components, energy dissipation and collision forces are obtained for various scenarios. Deformation of the inner hull is found to have a great effect on the responses of the LNG CCS, with approximately 160 mm deformation corresponding to the limit state. Densely arranged web frames can absorb over 35% of the collision energy and be proved to greatly enhance the crashworthiness of the FLNG side structures.

Similar content being viewed by others

References

ABS, 2006. Strength Assessment of Membrane-Type LNG Containment Systems Under Sloshing Loads, Guidance Notes.

Bond, J., Ferro, A. and Kennedy, S., 2011. FPSO side shell impact protection, Proceedings of the Offshore Technology Conference, Houston, No. 21309.

Chun, S.E., Hwang, J.O., Chun, M.S., Lee, J.M., Suh, Y.S., Hwangbo, S.M. and Wang, Z.H., 2011. Direct assessment of structural capacity against sloshing loads using nonlinear dynamic FE analysis including hull structural interactions, Proceedings of the 21st International Ocean and Polar Engineering Conference, Maui, 191–199.

Dobashi, H. and Usami, A., 2010. Structural response of the insulation box on NO.96 membrane containment system, Proceedings of the 20th International Offshore and Polar Engineering Conference, Beijing, 26–32,.

Hallquist, J.O., 2006. LS-DYNA Theory Manual, Livermore Software Technology Corporation, Rev.3.

Han, S., Lee, J.Y., Park, Y.I. and Che, J., 2008. Structural risk analysis of an NO.96 membrane-type liquified natural gas carrier in Baltic ice operation, Proceedings of the Institution of Mechanical Engineers, Part M: Journal of Engineering for the Maritime Environment, 222(4), 179–194.

Kenny, J.P. and Britain, G., 1988. Protection of Offshore Installations Against Impact: Background Report, Department of Energy Offshore Technology Information

Kim, J.H., Kim, D.H. and Song, H., 2012. Safety assessment of membrane type cargo containment systems in LNG carrier under the iceship repeated impact, Proceedings of the 22ed International Offshore and Polar Engineering Conference, Rhodes, 1194–1201.

Kim, J.H., Oh, H.K. and Kim, D.H., 2011. Safety assessment of cargo containment systems in LNG carriers under the impact of icebergship collision, Proceedings of the 30th International Conference on Ocean, Offshore and Arctic Engineering, Rotterdam, 975–982.

Kim, K.S., Kim, M.H. and Park, J.C., 2010. Dynamic coupling between ship motion and three-layer-liquid separator by using moving particle simulation, International Journal of Offshore and Polar Engineering, 24(2), 122–128.

Kõrgesaar, M. and Ehlers, S., 2015. An assessment procedure of the crashworthiness of an LNG tanker side structure, Ship Technology Research, 57(2), 108–119.

Lee, S.G., Lee, I.H., Baek, Y.H., Nicolas, C., Soizic, L.G., and Jean, M.Q., 2010. Membrane-type LNG carrier side collision with iceberg-effect of impact conditions on structural response through sensitivity analysis, Proceedings of the 6th Annual Arctic Shipping Summit, International Conference and Seminar, Helsinki.

Lee, S.G. and Nguyen, H.A., 2011. LNGC collision response analysis with iceberg considering surrounding seawater, Proceedings of the 21st International Offshore and Polar Engineering Conference, Maui, 1129–1235.

Lu, Y., Teng, B., Qi, E.R. and Chen, X.P., 2012. Structural dynamic response study of large LNG carriers under sloshing impacts in tanks, Journal of Ship Mechanics, 16(12), 1427–1438.

LR, 2009. Sloshing Assessment Guidance Document for Membrane Tank LNG Operations, Additional Design Procedures, Version 2.

NORSOK Standard, 2013. Design of Steel Structures, N-004, Rev. 3.

Paik, J.K., 2006. Limit state design technology for a membrane type liquid natural gas cargo containment system under sloshing impacts, Marine Technology, 43(3), 126–134.

Paik, J.K., Choe, I.H. and Thayamballi, A.K., 2002. Predicting resistance of spherical-type LNG carrier structures to ship collisions, Marine Technology, 39(2), 86–94.

Park, D.K., Kim, B.J., Seo, J.K., Ha, Y.C., Matsumoto, T., Byeon, S.H. and Paik, J.K., 2014. Safety of FLNG Hull Structures in Collisions with Icebergs in An Arctic Environment, SNAME Maritime Convention, Houston, USA.

Pedersen, P.T. and Zhang, S.M., 1998. On impact mechanics in ship collisions, Marine Structures, 11(10), 429–449.

Shaposhnikov, V.M., Nesterov, A.B., Aleksandrov, A.V. and Vasilik, E.G., 2014. Safety of LNG transportation in Arctic conditions when using systems of various types, Proceedings of the 33rd International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, No. 23439.

Wang, B., Yu, H.C., Basu, R., Lee, H., Kwon, J.C., Jeon, B.Y., Kim, J.H., Daley, C. and Kendrick, A., 2008. Structural response of cargo containment systems in LNG carriers under ice loads, Proceedings of the 8th International Conference and Exhibition on Performance of Ships and Structures in Ice, Banff, No. 134.

Wang, B., Yu, H.C. and Basu, R., 2008. Ship and ice collision modeling and strength evaluation of LNG ship structure, Proceedings of the 27th International Conference on Offshore Mechanics and Arctic Engineering, Estoril, 911–918.

Wang, B., Shin, Y., Han, S.K., Kim, Y.S. and Park, Y.I., 2009. Sloshing model tests and strength assessment of the NO.96 containment system, Proceedings of the 19th International Offshore and Polar Engineering Conference, Osaka, 261–268.

Xu, Q.W., Hu, Z.Q., Xie, B. and Zhao, J.R., 2015. Research on hydrodynamics of an FLNG system in side-by-side offloading operation with LNGC, China Offshore Oil and Gas, 27(2), 112–119. (in Chinese)

Zhang, A. and Suzuki, K., 2007. A comparative study of numerical simulations for fluid–structure interaction of liquid-filled tank during ship collision, Ocean Eng., 34(5), 645–652.

Zhang, A. and Suzuki, K., 2006. Numerical simulation of fluid–structure interaction of liquid cargo filled tank during ship collision using the ALE finite element method, International Journal of Crashworthiness, 11(4), 291–298.

Zhao, W.H., Yang, J.M., Hu, Z.Q. and Xiao, L.F., 2012a. Experimental investigation of effects of inner-tank sloshing on hydrodynamics of an FLNG system, Journal of Hydrodynamics, Ser. B, 24(1), 107–115.

Zhao, W.H., Yang, J.M. and Hu, Z.Q., 2012b. Hydrodynamic interaction between FLNG vessel and LNG carrier in side by side configuration, Journal of Hydrodynamics, Ser. B, 24(5), 648–657.

Zhao, W.H., Yang, J.M., Hu, Z.Q. and Tao, L.B., 2014. Prediction of hydrodynamic performance of an FLNG system in side-by-side offloading operation, J. Fluids Struct., 46, 89–110.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: This work was financially supported by the State Key Laboratory of Hydraulic Engineering Simulation and Safety, Tianjin University (Grant No. HESS-1404), and the National Natural Science Foundation of China (Grant No. 51239007).

Rights and permissions

About this article

Cite this article

Hu, Zq., Zhang, Dw., Zhao, Dy. et al. Structural safety assessment for FLNG-LNGC system during offloading operation scenario. China Ocean Eng 31, 192–201 (2017). https://doi.org/10.1007/s13344-017-0023-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13344-017-0023-4