Abstract

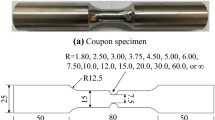

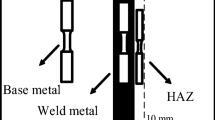

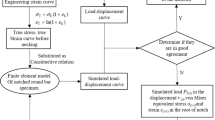

The fracture failure of high-strength steel has an important relationship with the stress state. In order to predict the fracture failure of high-strength steel under different stress conditions, based on the void growth model (VGM), a fracture model which comprehensively considers the effect of stress triaxiality and the Lode parameter on fracture failure is proposed and is called LVGM. A batch of Chinese Q690D high strength steel round rods and plate shaped specimens reflecting different stress states were processed, and the monotonic tensile tests, the scanning electron microscopy tests and the finite element calculation were carried out to study the crack initiation of the specimens. The microscopic mechanism of the fracture damage of the specimens was analyzed. Based on the fracture test results of the specimens and the corresponding finite element analysis, the LVGM parameters of the Q690D high strength steel were calibrated. Finally, the LVGM was used to predict the crack initiation and fracture failure process of the specimens with initial gap. The prediction results are in good agreement with the experimental results, and the LVGM has better prediction accuracy than the VGM.

Similar content being viewed by others

References

Bai, Y. L., & Wierzbicki, T. (2008). A new model of metal plasticity and fracture with pressure and lode dependence. International Journal of Plasticity, 24, 1071–1096.

Ban, H. Y., Shi, G., Shi, Y. J., et al. (2011). Research progress on the mechanical property of high strength structural steels. Advanced Materials Research, 250–253, 640–648.

Ban, H. Y., Shi, G., Shi, Y. J., & Wang, Y. Q. (2012). Overall buckling behavior of 460MPa high strength steel columns: Experimental investigation and design method. Journal of Constructional Steel Research, 74(4), 140–150.

Ghajar, R., Mirone, G., & Keshavarz, A. (2013). Ductile failure of X100 pipeline steel-experiments and fractography. Materials and Design, 43, 513–525.

Gurson, A. L. (1977). Continuum theory of ductile rupture by void nucleation and growth: Part I—yield criteria and flow rules for porous ductile media. Journal of Engineering Materials and Technology, 99(1), 2–15.

Huang, X. W., & Zhao, J. (2017). A cumulative damage model for extremely low cycle fatigue cracking in steel structure. Structural Engineering and Mechanics, 62(2), 225–236.

Huang, X. W., Tong, L. W., Zhou, F., et al. (2013). Prediction of fracture behavior of beam-to-column welded joints using micromechanics damage model. Journal of Constructional Steel Research, 85, 60–72.

Huang, X. W., Ge, J. Z., Zhao, J., & Zhao, W. (2020). A continuous damage model of Q690D steel considering the influence of Lode parameter and its application. Construction and Building Materials, 262, 120067.

Jia, L. U., Ge, H. B., Shinohara, K., et al. (2016a). Experimental and numerical study on ductile fracture of structural steels under combined shear and tension. Journal of Bridge Engineering, 21(5), 04016008.

Jia, L. U., Ikai, T., Shinohara, K., & Ge, H. B. (2016b). Ductile crack initiation and propagation of structural steels under cyclic combined shear and normal stress loading. Construction and Building Materials, 112, 69–83.

Kanvinde, A. M., & Deierlein, G. G. (2006). Void growth model and the stress modified critical strain model to predict ductile fracture in structural steels. Journal of Structural Engineering, 132(12), 1907–1918.

Kanvinde, A. M., & Deierlein, G. G. (2007). Finite-element simulation of ductile fracture in reduced section pull-plates using micromechanics-based fracture models. Journal of Structural Engineering, 133(5), 656–664.

Kanvinde, A. M., Fell, B. V., Gomez, I. R., et al. (2008). Predicting fracture in structural fillet welds using traditional and micromechanical fracture models. Engineering Structures, 30(11), 3325–3335.

Langenberg P. (2008). Relation between design safety and Y/T ratio in application of welded high structural steels. In Proceedings of International Symposium on Applications of High Strength Steels in Modern Constructions and Bridges-Relationship of Design Specifications, Safety and Y/T Ratio. Beijing, pp. 28–46.

Liao, F. F., Wang, W., & Chen, Y. Y. (2012). Parameter calibrations and application of micromechanical fracture models of structural steels. Structural Engineering and Mechanics, 42(2), 153–174.

Liao, F. F., Wang, W., & Chen, Y. Y. (2015). Ductile fracture prediction for welded steel connections under monotonic loading based on micromechanical fracture criteria. Engineering Structures., 95, 16–28.

Li, W. C., Liao, F. F., Zhou, T. H., et al. (2016). Ductile fracture of Q460 steel: Effects of stress triaxiality and Lode angle. Journal of Constructional Steel Research, 123, 1–17.

Lou, Y., & Huh, H. (2013). Prediction of ductile fracture for advanced high strength steel with a new criterion: Experiments and simulation. Journal of Materials Processing Technology, 213(8), 1284–1302.

Malvern, L. E. (1969). Introduction to the Mechanics of a Continuous Medium. Upper Saddle River, New Jersey: Prentice-Hall Inc.

Pocock, G. (2006). High strength steel use in Australia, Japan and the US. The Structural Engineer, 84(21), 27–30.

Rasmussen, K. J. R., & Hancock, G. J. (1995). Tests of high strength steel columns. Journal of Constructional Steel Research, 34(1), 27–52.

Rice, J. R., & Tracey, D. M. (1969). On the ductile enlargement of voids in triaxial stress fields. Journal of the Mechanics and Physics of Solids, 17(3), 201–217.

Shi, G., Ban, H.Y., Shi, Y.J., et al. (2009). Recent research advances on the buckling behavior of high strength and ultra-high strength steel structures. Proceedings of the 2009 International Conference on Technology of Architecture and Structure. Shanghai.

Shi, G., Wang, M., Bai, Y., et al. (2012). Experimental and modeling study of high-strength structural steel under cyclic loading. Engineering Structures, 37, 1–13.

Sivakumaran, S K. (2008). Relevance of Y/T ratio in the design of steel structures. In Proceedings of International Symposium on Applications of High Strength Steels in Modern Constructions and Bridges-Relationship of Design Specifications, Safety and Y/T Rati. Beijing, pp. 54–63.

Smith, C. M., Deierlein, G. G., & Kanvinde, A. M. (2014). Prediction of Ultra-Low Cycle Fatigue and ductile fracture in large-scale tests of structural components using the Stress-Weighted Damage Model. NCEE 2014 - 10th U.S. National Conference on Earthquake Engineering: Frontiers of Earthquake Engineering. https://doi.org/10.4231/D3J678X5N.

Tvergaard, V., & Needleman, A. (1984). Analysis of the cup-cone fracture in a round tensile bar. Acta Metallurgica, 32(1), 157–169.

Wang, Y. Q., Zhou, H., Shi, Y. J., et al. (2011). Fracture prediction of welded steel connections using traditional fracture mechanics and calibrated micromechanics based models. International Journal of Steel Structures, 11, 351–366.

Acknowledgements

The work in this paper is financially sponsored by National Natural Science Foundation of China (No. 51608487) and National Key R&D Program of China (2016YFE0125600). This study is also supported by Key Science and Technology Program of Henan Province (No. 192102310221) and Key Project of Science and Technology of the Education Department of Henan Province (No. 17A130002)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, X., Ge, J., Zhao, J. et al. Experimental and Fracture Model Study of Q690D Steel Under Various Stress Conditions. Int J Steel Struct 21, 561–575 (2021). https://doi.org/10.1007/s13296-021-00456-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13296-021-00456-3