Abstract

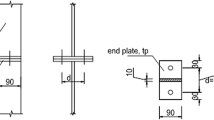

An experimental study for the structural behaviors of high strength aluminum alloys (7075-T6) single shear bolted connections with three types of bolt arrays has been carried out by authors. Out-of-plane deformation in the direction of plate thickness (hereafter, curling) occurred in some specimens with long end distances parallel to the direction of applied force. It is known that the curling reduced ultimate strength for curled specimens and it contributed to deciding the ultimate state of 7075-T6 bolted connections. In this paper, finite element analysis model has been developed based on the previous experimental results of 7075-T6 four-bolted connections and previous finite element analysis procedures related to singe shear bolted connections. The validation of finite element analysis method for predicting the ultimate behaviors of 7075-T6 bolted connections was verified through the comparison of test results and analysis results. Additional analyses with extended parameters of end and edge distances were conducted. As a result, strength reduction ratio (up to maximum 19%) by curling was investigated quantitatively and the curling occurrence conditions for end distance and edge distance were presented. In addition, analysis strengths were compared with design strengths by AAA (American Aluminum Association), AISI (American Iron Steel Institute) design specifications and proposed equation for 6061-T6 aluminum alloys four-bolted connections. Lastly, revised strength equation was suggested considering the actual fracture mechanism at ultimate state and curling influence (strength drop) by bolt bearing action.

Similar content being viewed by others

References

ABAQUS. (1998). Theory manual Ver.5.8. Pawtucket: Hibbitt, Karlsson & Sorensen Inc.

ABAQUS. (2003). ABAQUS Ver.6.4, analysis user‘s manual. Pawtucket: ABAQUS Inc.

Aluminum Association (AAA). (1987). Structural design with aluminum (1st ed.). Washington, DC: Aluminum Association (AAA).

Aluminum Association (AAA). (2010). Aluminum design manual. Washington, DC: The Aluminum Association.

Aluminum Association of Japan. (2007). Recommendation for the design of aluminum alloy structures. Tokyo: Aluminum Association of Japan.

American Iron and Steel Institute (AISI). (2016). North American specification for the design of cold-formed steel structural members, AISI S100-16. Washington, DC: American Iron and Steel Institute (AISI).

American Society for Testing and Materials (ASTM). (2014). Standard specification for aluminum and aluminum-alloy sheet and plate ASTM: B209M-14. West Conshohocken: American Society for Testing and Materials.

Cho, Y. H., & Kim, T. S. (2016). Estimation of ultimate strength in single shear bolted connections with aluminum alloys (6061-T6). Thin-Walled Structures, 101, 43–57.

Chung K. R., & Um K. H., (2004). Structural design and construction of aluminum dome for Yong-San station. Korean association of spatial structures, 4(4), 15–19 (in Korean).

Chung, K. R., Kim, Y. J., Kim, M. H., & Um, K. H. (2001). Large spatial structures using Aluminum dome. Journal of The Korean Association for Spatial Structures, 1(2), 30–36 (in Korean).

Eurocode 9. (2000). Design of aluminum structures—Part 1-1: General rules—General rules and rules for buildings, DD ENV 1999-1-1, EC9.

Kim, T. S. (2012). Block shear strength of single shear four-bolted connections with aluminum alloys—Experiment and design strength comparison. Applied Mechanics and Materials, 217–219, 386–389.

Kim, T. S., & Cho, Y. H. (2014). Investigation on ultimate strength and failure mechanism of bolted joints in two different aluminum alloys. Materials and Design, 58, 74–88.

Kim, T. S., Kim, M. S., & Cho, T. J. (2018). Parametric study on ultimate strength of four-bolted connections with cold-formed carbon steel. International Journal of Steel Structures, 18(1), 265–280.

Kim, T. S., & Kuwamura, H. (2007). Finite element modeling of bolted connections in thin-walled stainless steel plates under static shear. Thin-Walled Structures, 45, 407–421.

Kim, T. S., Kuwamura, H., & Cho, T. J. (2008). A parametric study on ultimate strength of single shear bolted connections with curling. Thin-Walled Structures, 46, 38–53.

Kim, T. S., & Lim, J. S. (2013). Ultimate strength of single shear two-bolted connections with austenitic stainless steel. International Journal of Steel Structures, 13(1), 1–12.

Acknowledgements

This research was supported by the Human Resources Development of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Korea government Ministry of Trade, industry and Energy (No. 20184030201900).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hwang, B., Kim, T. An Investigation on Ultimate Strength of High Strength Aluminum Alloys Four-Bolted Connections with Out-of-plane Deformation. Int J Steel Struct 19, 1158–1170 (2019). https://doi.org/10.1007/s13296-018-0195-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13296-018-0195-7