Abstract

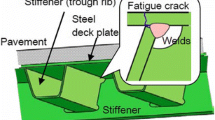

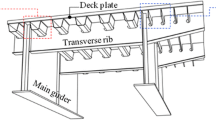

Under heavy traffic conditions, some fatigue cracks have been found at welding joints between U-shaped ribs “trough ribs” and deck plates. Fatigue cracks along thickness direction of deck plate from root tip are important because visual crack detection from outside is limited. In this paper, new functional steel plates with initiation resistance of fatigue crack at weldment and propagation resistance at base material are applied to deck plate to evaluate improvement of fatigue life. We conducted fixed-point fatigue tests with real scale partial models consisted with one trough rib and a transverse girder, and the elastic FEM (Finite Element Method) analysis corresponding to the fatigue test specimen. Based on these results, we studied the fatigue properties which focused on the difference between conventional steel plates and newly developed steel plates, FCA (Fatigue Crack Arrester). Fatigue cracks were initiated from root tip of welded joints between a trough rib and a deck plate. It is clarified that FCA steel plates instead of conventional steel plates can improve the fatigue life under the same welding conditions. This improvement effect becomes much clearer in the high cycle region, which is noticeable at the operation and management stage of bridges.

Similar content being viewed by others

References

Arimochi, K., Onishi, K., Konda, N., Nagaki, H., Morishita, Y., Takaba, S., and Yasuda, O. (2006). “Study for improvement of fatigue strength at welded joints between deck plate and U-rib with fatigue crack arrester steel.” Proc. of Symposium on Welding Structures, pp. 233–236 (in Japanese).

Hara, J., Takaoka, Y., Konda, N., Arimochi, K., Inami, A., Dobashi, H., and Yamamoto, N. (2010). “Practical application of high fatigue-strength steel to weldments (FCA-W) in an LNG carrier.” Proc. 24th Asian-Pacific Technical Exchange and Advisory Meeting on Marine Structures, pp. 263–266.

Ichimiya, M., Kasugai, T., Kiyokawa, S., Andou, K., Konda, N., and Arimochi, K. (2008a). “A proposal for evaluation method of fatigue crack initiation and propagation in orthotropic steel deck.” Proc. 63rd Annual Conference of Japan Society of Civil Engineering, pp. 413–414 (in Japanese).

Ichimiya, M., Kasugai, T., Kiyokawa, S., Andou, K., Konda, N., Arimochi, K. (2008b). “Improvement of fatigue strength by application of fatigue crack arrester FCA.” Proc. 63 rd Annual Conference of Japan Society of Civil Engineering, pp. 415–416 (in Japanese).

JSSC (1998). Fatigue Design Guidance for welded steel structures. Japanese Society of Steel Construction, Japan (in Japanese).

Konda, N., fujiwara, K., Arimochi, K., Onishi, K., and Yamashita, M. (2005a). “Development of new steel plate possessing self-suppression effect of fatigue-crack propagation and properties of welded joints.” Journal of Welding Society, 74(4), pp. 201–204 (in Japanese).

Konda, N., Arimochi, K., and Hasegawa, K. (2005b). “Properties in welded joints of anti-fatigue steel plates.” Journal of Welding Society, 74(6), pp. 421–425 (in Japanese).

Konda, N., Nishio, M., Onishi, K., Arimochi, K., Yasuda, O., Nagaki, H., Yamano, T., Morishita, H., and Takaba, S. (2008a). “Study on improvement of fatigue strength of welded structures by new functional structural steel plates.” Welding in the World, 52(5/6), pp. 95–109.

Konda, N., Arimochi, K., Inami, A., and Sakaibori, H. (2008b). “High tensile structural steel plate with superior fatigue properties.” Welding Technology, 56, pp. 86–93 (in Japanese).

Konda, N., Inami, A., Arimochi, K., Takaoka, Y., Yoshida, T., and Lotsberg, I. (2010). “A proposal design S-N curve for steel with improved fatigue resistance (FAC Steels).” Proc. 11 th International Symposium on Practical Design of Ships and Other Floating Structures, pp. 1233–1242.

Miki, C., Konishi, T., and Suganuma, H. (2007). “New type of steel orthotropic system.” Proc. 10 th Symposium on Steel Structure and Bridges, pp. 71–91 (in Japanese).

Terao, K. and Suzuki, K. (1996). “A parametric study of details at weld between transverse and longitudinal ribs in orthotropic steel deck bridges.” Technical Report of Yokogawa Bridge Corp., 25, pp. 87–95 (in Japanese).

Une, T., Oshiro, T., Maeda, T., Tonegawa, T., Matsuno, M., and Kamijyo, T. (2009). “Application of fatigue crack arrester FCA to steel concrete combined bridge.” Proc. 64 th Annual Conference of Japan Society of Civil Engineering, pp. 889–890 (in Japanese).

Yamada, K. (2007). “Fatigue damage in orthotropic steel deck under heavy wheel loads around Nagoya.” Proc. 10 th Symposium on Steel Structure and Bridges, pp. 11–18 (in Japanese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Note.-Discussion open until August 1, 2013. This manuscript for this paper was submitted for review and possible publication on May 9, 2012; approved on March 11, 2013.

Rights and permissions

About this article

Cite this article

Konda, N., Nishio, M., Ichimiya, M. et al. Development of fatigue test method and improvement of fatigue life by new functional steel plates for welding of trough rib and deck plate of orthotropic decks. Int J Steel Struct 13, 191–197 (2013). https://doi.org/10.1007/s13296-013-1018-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13296-013-1018-5