Abstract

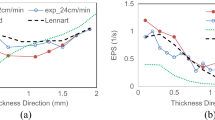

In this study, we conducted fatigue tests under various stress ratios using cruciform welded joints to confirm the benefit of Ultrasonic Impact Treatment (UIT) for the fatigue strength of welded joints. The material used in the experiment is the JIS SBHS500 high performance steel for bridges. The fatigue life of the peened weld joint by UIT is significantly longer than that of as-welded joints, especially at a low stress ratio. We also estimated the fatigue life of these cruciform joints by crack growth analysis based on the crack opening and closure simulation using the modified strip-yielding model, accounting for the residual stress distribution created by welding or UIT. These estimation results demonstrate good agreement with experimental results obtained at various stress ratios.

Similar content being viewed by others

References

API (2000). API Recommended Practice 579, Fitness for Service. American Petroleum Institute.

BS (2005). Guide to methods for assessing the acceptability of flaws in metallic structures. BS 7910, British Standard.

Glinka, G. (1985). “Calculation of inelastic notch-tip strain-stress histories under cyclic loading.” Eng. Fract. Mech. J., 22(5), pp. 839–384.

Haagensen, P. J., Statnikov, E. S., and Lopez-Martinez, L. (1998). “Introductory fatigue tests on welded joints in high strength steel and aluminium treated by various improvement methods including ultrasonic impact treatment (UIT).” Proc. 51st Annual Assembly of the International Institute of Welding, IIW Doc. XIII-1748-98, Hamburg.

Hobbacher, A. F. (2009). “The New IIW recommendations.” Int. J. Fatigue, 31, pp. 50–58.

JSSC (1993). Guidelines for fatigue design of steel structures. Japanese Society of Steel Construction (in Japanese).

JWES (2007). Method of assessment for flaws in fusion welded joints with respect to brittle fracture and fatigue crack growth. WES 2805, The Japan Welding Engineering Society, Japan.

Mori, T., Shimauki, H., and Tanaka, M. (2012). “Effect of UIT on fatigue strength of web-gusset welded joints considering service condition of steel structures.” Welding in the World, 56(9–10), pp. 141–149.

Nose, T. (2008). “Ultrasonic peening method for fatigue strength improvement.” Journal of the Japan Welding Society, 77(3), pp. 4–7 (in Japanese).

Okawa, T., Shimanuki, H., and Nose, T. (2009a). “Fatigue Life Prediction of Welded Structures under Variable Amp. Loading.” Proc. 2nd Int. Conf. on Material and Component Performance under Variable Amp. Loading, Vol. 1, Germany, pp. 433–442.

Okawa, T., Shimanuki, H., Nose, T., and Suzuki, T. (2009b). “Fatigue life prediction of welded joints, Analysis of fatigue strength improvement by ultrasonic impact treatment.” Proc. Welded Structure Symposium, pp. 483–486 (in Japanese).

Okawa, T. and Sumi, Y. (2008). “A Computational approach for fatigue crack propagation in ship structures under random sequence of clustered loading.” J. Mar. Sci. Technol., 13, pp. 416–427.

Suzuki, T., Imafuku, M., Okawa, T., Shimanuki, H., Nose, T., Suzuki, H., and Moriai, A. (2010). “Residual stress measurement of UIT (Ultrasonic Impact Treatment) treated steel plate by neutron diffraction method.” Proc. 45th Symposium on X-Ray Studies on Mechanical Behaviour of Materials, Japan (in Japanese).

Tsuji, I. (1990). Estimation of stress concentration factor at weld toe of non-load carrying fillet welded joints. The Japanese Society of Naval Architects and Ocean Engineers, Vol. 80, pp. 241–251 (in Japanese).

Ueda, Y., Murakawa, H., and Ma, N. X. (2007). Specific manual on welding distortion and residual stress for engineers. Sanpo Publications, Japan (in Japanese).

Wang, T., Wang, D., Huo, L., and Zhang, Y. (2009). “Discussion on fatigue design of welded joints enhanced by ultrasonic peening treatment (UPT).” International Journal of Fatigue, 31, pp. 644–650.

Yamaguchi, A., Togasaki, U., Honda, T., Sasaki, T., and Tsuji, H. (2011). “Improvement on fatigue strength of welded joints in high tensile strength steels by means of UIT.” Transaction of The Japan Society of Mechanical Engineers Series A, 77(777), pp. 690–693.

Author information

Authors and Affiliations

Corresponding author

Additional information

Note.-Discussion open until August 1, 2013. This manuscript for this paper was submitted for review and possible publication on June 30, 2012; approved on February 22, 2013.

Rights and permissions

About this article

Cite this article

Shimanuki, H., Okawa, T. Effect of stress ratio on the enhancement of fatigue strength in high performance steel welded joints by ultrasonic impact treatment. Int J Steel Struct 13, 155–161 (2013). https://doi.org/10.1007/s13296-013-1014-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13296-013-1014-9