Abstract

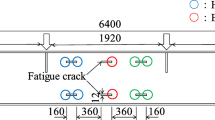

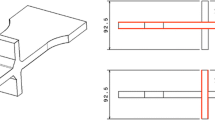

In the fabrication of steel bridges, prior to painting, blast cleaning is performed to clean the surfaces and to increase the adhesive properties of the surfaces for the subsequent painting. In addition to these objectives, blast cleaning can improve the fatigue strength of welded joints, as a result of the impact of forcibly propelled abrasive materials on the welded joints. A series of fatigue tests were carried out on the five different types of welded joints: one-side out-of-plane gusset fillet welded joints, both-side out-of-plane gusset fillet welded joints, non-load-carrying rib fillet welded cruciform joints, butt welded joints, and a large-scale model beam with out-of-plane gusset welded joints, and under the three different types of load conditions: uniaxial tension, out-of-plane bending, or in-plane bending stress cycles. Drawing on previous fatigue test results that include unpublished data, this paper presents the beneficial effects of blast cleaning for the subsequent painting applications on the fatigue strength improvement of welded joints and also presents a simple quality control method for the blast cleaning process that improves the fatigue strength.

Similar content being viewed by others

References

Haagensen, P. J., Dragen, A., Slind, T., and Orjasaeter, O. (1987). “Prediction of the improvement in fatigue life of welded joints due to grinding, TIG dressing — Weld shape control and shot peening.” Steel in Marine Structures, 15, pp. 689–698.

ISO (1998). Paints and varnishes-corrosion protection of steel structures by protective paint systems. Part 4: Types of surface and surface preparation. ISO 12944-4, International Organization for Standardization, Switzerland.

JSSC (1993). Fatigue design recommendations for steel structures. Japan Society of Steel Construction, Gihodo Shuppan (in Japanese).

Kim, I. T., Nhan, L. V. P., Kim, K. J., and Lee, D. U. (2008a). “The effect of blast cleaning for steel bridge painting on fatigue behavior of out-of-plane gusset welded joints.” Journal of Korean Society of Steel Construction, KSSC, 20(5), pp. 583–590 (in Korean).

Kim, I. T., Nhan, L. V. P., and Lee, D. U. (2008b). “Fatigue behavior of blast-treated out-of-plane gusset fillet welded joints.” International Journal of Steel Structure, 8(3), pp. 155–161.

Kim, I. T., Jung, Y. S., Kim, K. J., and Lee, D. U. (2009). “Effect of blast cleaning on fatigue behavior of non-load-carrying fillet welded cruciform joints.” Journal of Korean Society of Steel Construction, KSSC, 21(1), pp. 55–62 (in Korean).

Kim, I. T., Jung, Y. S., and Lee, D. U. (2011). “Improving fatigue strength of weld joints by blast cleaning used in painting steel bridge.” Journal of Korean Society of Steel Construction, KSSC, 23(2), pp. 137–146 (in Korean).

Kim, I. T. and Yamada, K. (2005). “Fatigue life evaluation of welded joints under combined normal and shear stress cycles.” International Journal of Fatigue, 27, pp. 695–701.

Kirkhope, K. J., Bell, R., Caron, L., Basu, R. I., and Ma, K. -T. (1999). “Weld detail fatigue life improvement techniques. Part 1: review.” Marine Structures, 12, pp. 447–474.

Kobayashi, M., Matsui, T., and Murakami, Y. (1998). “Mechanism of creation of compressive residual stress by shot peening.” International Journal of Fatigue, 20, pp. 351–357.

KS (2008). Rolled steels for welded structures. KS D 3515, Korean Agency for Technology and Standards (in Korean).

Ohta, A., Sasaki, S., Inagaki, M., Kamakura, M., Niei, M., and Kosuge, M. (1981). “Effect of residual stresses on threshold level for fatigue crack propagation in welded joints of SM50B steel.” Transactions of the Japan Welding Society, 50, pp. 31–38 (in Japanese).

SSPC (2009). SURFACE PREPARATION SPECIFICATION Surface preparation commentary for steel and concrete substrates. SSPC-SP COM, The Society for Protective Coatings, Pittsburgh.

SSPC (2007). JOINT SURFACE PREPARATION STANDARD Near-White Metal Blasting Cleaning. SSPC-SP 10/NACE No. 2, The Society for Protective Coatings, Pittsburgh.

Tebedge, N., Alpsten, G., and Tall, L. (1973). “Residualstress Measurement by the sectioning method.” Experimental Mechanics, 13, pp. 88–96.

Author information

Authors and Affiliations

Corresponding author

Additional information

Note.-Discussion open until August 1, 2013. This manuscript for this paper was submitted for review and possible publication on June 18, 2012; approved on February 19, 2013.

Rights and permissions

About this article

Cite this article

Kim, IT., Jeong, YS. Fatigue strength improvement of welded joints by blast cleaning for subsequent painting. Int J Steel Struct 13, 11–20 (2013). https://doi.org/10.1007/s13296-013-1002-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13296-013-1002-0