Abstract

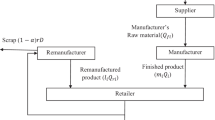

Every organisation has an upper limit to the number of orders or products that it can manufacture or remanufacture per unit time. In reverse logistics operations, capacity limits can lead to inefficiencies in the remanufacturing process. In this paper, comparisons were made of the Bullwhip effect (BWE) in closed-loop systems that have collection and remanufacturing capacity limits and those that do not. Collection and remanufacturing capacity limits were introduced for a system where a company had to collect ‘enough’ products before remanufacturing can begin. This introduced collection backlogs, remanufacturing backlogs and remanufacturing downtimes to the closed loop supply chain (CLSC). By adopting a systems dynamics approach, the research performed ‘what-if’ analyses of the closed-loop system under different levels of the factors under investigation. Two case studies were investigated: one remanufacturing electric vehicle batteries (low demand, slow moving item) and the other remanufacturing kitchen appliances (high demand, fast moving item). Firstly, introducing collection and remanufacturing capacity limits in the reverse chain increased the BWE to a level higher than the reverse chain without any capacity limits, but not to the level of the forward chain without any product returns. Secondly, introducing collection and remanufacturing capacity limits for a closed-loop system where a company had to collect ‘enough’ products before remanufacturing begins had different impacts depending on the product demand size and speed. The presence of external returns by other parties not regulated by an organisation had an impact of lowering the BWE in the closed-loop system and it also impacted how the other factors under investigation affected the Bullwhip effect. These findings were used to provide managerial insights for organisations venturing into reverse logistics.

Similar content being viewed by others

References

Adenso-Díaz B, Moreno P, Gutiérrez E, Lozano S (2012) An analysis of the main factors affecting bullwhip in reverse supply chains. Int J Prod Econ 135(2):917–928. https://doi.org/10.1016/j.ijpe.2011.11.007

Aksoy HK, Gupta SM (2001) Capacity and buffer trade-offs in a remanufacturing system. In: Proceedings of the SPIE International Conference on Environmentally Conscious Manufacturing II, pp 167–174. https://doi.org/10.1117/12.455276

Asif FMA, Bianchi C, Rashid A, Nicolescu CM (2012) Performance analysis of the closed loop supply chain. J Remanufacturing 2(4):1–21

Cannella S, Bruccoleri M, Framinan JM (2016) Closed-loop supply chains : what reverse logistics factors in fl uence performance ? Int J Prod Econ 175:35–49. https://doi.org/10.1016/j.ijpe.2016.01.012

Cannella S, Ciancimino E, Marquez AC (2008) Capacity constrained supply chains : a simulation study. Int J Simul Process Model 4(2):139. https://doi.org/10.1504/IJSPM.2008.022075

Cannella S, Dominguez R, Ponte B, Framinan JM (2018) Capacity restrictions and supply chain performance: Modelling and analysing load-dependant lead times. Int J Prod Econ 204:264–277

Chen L, Lee HL (2012) Bullwhip effect measurement and its implications bullwhip effect measurement and its implications. Oper Res 60(4):771–784

Chittamvanich S (2007) Adjusting remanufacturing capacity using sales and return information. In: Retrospective theses and dissertations 15508. UNIVERSITY, IOWA STATE

Chopra S, Meindl P (2007) In: Pfaltzraff M (ed) SUPPLY CHAIN MANAGEMENT: Strategy, Planning and Operation, 3rd edn. Pearson prentice hall

Das D, Dutta P (2013) A system dynamics framework for integrated reverse supply chain with three way recovery and product exchange policy. Comput Ind Eng 66(4):720–733. https://doi.org/10.1016/j.cie.2013.09.016

de Souza R, Zice S, Chaoyang L (2000) Supply chain dynamics and optimization. Integr Manuf Syst 11(5):348–364

Ding X, Gan X (2009) System dynamics model to analysis oscillation and amplification in the closed-loop supply chain. In: International Conference on Management of e-Commerce and e-Government, pp 343–346. https://doi.org/10.1109/ICMeCG.2009.70

Disney SM, Lambrecht MR (2008) On replenishment rules , forecasting and the bullwhip effect in supply chains. Foundations and Trends in Technology, Information and Operations Management 2(1):1–80

Dominguez R, Ponte B, Cannella S, Framinan JM (2019) On the dynamics of closed-loop supply chains with capacity constraints. Comput Ind Eng 128(December 2018):91–103. https://doi.org/10.1016/j.cie.2018.12.003

Editor, M. B. (2014). The power of multivariate ANOVA (MANOVA) Available https://blog.minitab.com/blog/adventures-in-statistics-2/the-power-of-multivariate-anova-manova [13 March 2019]

El-Beheiry, M., Wong, C. Y., & El-Kharbotly, A. (2004). Empirical quantification of bullwhip effect ( with application to a toy supply chain ). In Thirteenth International Working Seminar on Production Economics

Evans G, Naim MM (1994) The dynamics of capacity constrained supply chains. In: International Systems Dynamics Conference, pp 28–33

Feng L, Zhang J, Tang W (2013) Optimal control of production and remanufacturing for a recovery system with perishable items. Int J Prod Res 51(13):3977–3994. https://doi.org/10.1080/00207543.2012.762133

Forrester JW, Senge PM (1980) Tests for building confidence in systems dynamics models. In: TIMS Studies in the Management Sciences, 14th edn. North Holland Publishing Company, pp 209–228

Fransoo JC, Wouters MJF (2000) Measuring the bullwhip effect in the supply chain. Supply Chain Manag 5(2):78–89. https://doi.org/10.1108/13598540010319993

Georgiadis P, Athanasiou E (2013) Flexible long-term capacity planning in closed-loop supply chains with remanufacturing. Eur J Oper Res 225(1):44–58. https://doi.org/10.1016/j.ejor.2012.09.021

Gong X, Chao X (2013) Technical note—optimal control policy for capacitated inventory systems with remanufacturing. Oper Res 61(3):603–611. https://doi.org/10.1287/opre.2013.1168

He S, Yuan X, Zhang X (2016) The Government’s environment policy index impact on recycler behavior in electronic products closed-loop supply chain. Discret Dyn Nat Soc 2016:1–8. https://doi.org/10.1155/2016/7646248

Heydari J, Govindan K, Jafari A (2017) Reverse and closed loop supply chain coordination by considering government role. Transp Res Part D: Transp Environ 52:379–398. https://doi.org/10.1016/j.trd.2017.03.008

Heydari J, Govindan K, Sadeghi R (2018) Reverse supply chain coordination under stochastic remanufacturing capacity. Int J Prod Econ 202(March):1–11. https://doi.org/10.1016/j.ijpe.2018.04.024

Hillston J (2003) Performance modelling-lecture 16: model validation and verification. School of Informatics, Univ. of Edinburgh, Scotland

Hintze JL (2007) D-optimal designs. In: NCSS User’s Guide II Descriptive Statistics, Means, Quality Control, and Design of Experiments. NCSS, p 267-1–23

Holweg, M., & Disney, S. M. (2005). The evolving frontiers of the bullwhip effect. In EUROMA Annual Conference. Budapest

Hosoda T, Altekin FT, Sahin G, Disney SM, Gavirneni S (2015) The impact of information sharing, random yield correlation and lead times in closed loop suply chains. Eur J Oper Res 246(3):827–836. https://doi.org/10.1016/j.ejor.2015.05.036

Hussain M, Drake PR (2011) Analysis of the bullwhip effect with order batching in multi-echelon supply chains. Int J Phys Distrib Logistics Manage 41(8):797–814. https://doi.org/10.1108/09600031111166438

Lee HL, Padmanabhan V, Whang S (1997) Information distortion in a supply chain: the bullwhip effect. Manag Sci 43(4):546–558. https://doi.org/10.1287/mnsc.43.4.546

Lieckens K (2009) Reverse logistics network design: the impact of Lead times and Stochasticity. Unpublished thesis, University of Antwerp, Belgium

Ma L, Chai Y, Zhang Y, Zheng L (2014) Modelling and analysis of the bullwhip effect in remanufacturing. Appl Mech Mater 541–542:1556–1561

Nepal B, Murat A, Chinnam RB (2012) The bullwhip effect in capacitated supply chains with consideration for product life-cycle aspects. Int J Prod Econ 136:318–331

Poles R, Cheong F (2011) An investigation on capacity planning and Lead times for remanufacturing systems using system dynamics BT. In: 44th Hawaii International Conference on System Sciences (HICSS 2011), pp 1–10. https://doi.org/10.1109/HICSS.2011.60

Poles R (2013) System dynamics modelling of a production and inventory system for remanufacturing to evaluate system improvement strategies. Int J Prod Econ 144(1):189–199. https://doi.org/10.1016/j.ijpe.2013.02.003

Ponte B, Wang X, de la Fuente D, Disney SM (2017) Exploring nonlinear supply chains : the dynamics of capacity constraints. Int J Prod Res 55(14):4053–4067. https://doi.org/10.1080/00207543.2016.1245884

Prahinski C, Kocabasoglu C (2006) Empirical research opportunities in reverse supply chains. Int J Manag Sci 34:519–532. https://doi.org/10.1016/j.omega.2005.01.003

Souza GC (2013) Closed-Loop Supply Chains : A Critical Review , and Future Research*. Decis Sci 44(1):7–38

Spiegler VLM, Naim MM (2014) The impact of freight transport capacity limitations on supply chain dynamics. Int J Log Res Appl 17(1):64–88. https://doi.org/10.1080/13675567.2013.838012

Sterman JD (2000) Business Dynamics: Systems Thinking Modelling for a complex World (Internatio). McGraw- Hill Irwin

Sy C (2017) A policy development model for reducing bullwhips in hybrid production-distribution systems. Int J Prod Econ 190:67–79. https://doi.org/10.1016/j.ijpe.2016.09.005

Tang O, Naim MM (2004) The impact of information transparency on the dynamic behaviour of a hybrid manufacturing/remanufacturing system. Int J Prod Res 42(19):4135–4152. https://doi.org/10.1080/00207540410001716499

Tombido L, Baihaqi I (2020) The impact of a substitution policy on the bullwhip effect in a closed loop supply chain with remanufacturing. J Remanuf 10(3):177–205. https://doi.org/10.1007/s13243-020-00084-w

Tombido L, Louw L, van Eeden J (2020) The bullwhip effect in closed-loop supply chains: a comparison of series and divergent networks. J Remanuf 10(3):207–238. https://doi.org/10.1007/s13243-020-00085-9

Turrisi M, Bruccoleri M, Cannella S (2013) Impact of reverse logistics on supply chain performance. Int J Phys Distrib Logist Manag 43(7):564–585. https://doi.org/10.1108/IJPDLM-04-2012-0132

Van der Laan E, Salomon M, Dekker R, Van Wassenhove L (1999) Inventory control in hybrid systems with remanufacturing. Manag Sci 45(5)733–747

Vlachos D, Georgiadis P, Iakovou E (2007) A system dynamics model for dynamic capacity planning of remanufacturing in closed-loop supply chains, 34, 367–394. https://doi.org/10.1016/j.cor.2005.03.005

Wan Z, Li C-BC (2012) Bullwhip effect in closed-loop supply chain based on system dynamics. Comput Integr Manuf Syst 18(5):1093–1098

Wang Q, Li J, Yan H, Zhu SX (2016) Optimal remanufacturing strategies in name-your-own-price auctions with limited capacity. Int J Prod Econ 181:113–129. https://doi.org/10.1016/j.ijpe.2016.01.008

Wang X, Disney SM (2015) The bullwhip effect: Progress, trends and directions. Eur J Oper Res 250:691–701. https://doi.org/10.1016/j.ejor.2015.07.022

Wei S, Tang O, Sundin E (2015) Core (product) acquisition management for remanufacturing: a review. J Remanuf 5(1):4. https://doi.org/10.1186/s13243-015-0014-7

Yuan X, Zhang X (2015) Recycler reaction for the government behavior in closed-loop supply chain distribution network : based on the system dynamics. Discret Dyn Nat Soc 2015:11

Zanoni S, Ferretti I, Tang O (2006) Cost performance and bullwhip effect in a hybrid manufacturing and remanufacturing system with different control policies. Int J Prod Res 44(18–19):3847–3862. https://doi.org/10.1080/00207540600857375

Zhang X, Yuan X (2016) The system dynamics model in electronic products closed-loop supply chain distribution network with three-way recovery and the old-for-new policy. Discret Dyn Nat Soc 2016:10

Zhou L, Disney SM (2006) Bullwhip and inventory variance in a closed loop supply chain. OR Spectr 28(1):127–149. https://doi.org/10.1007/s00291-005-0009-0

Zhou L, Disney SM, Lalwani CS, Wu H (2004) Reverse logistics: a study of bullwhip in continuous time. In: Proceedings of the 5th World Congress on Intelligent Control and Automation (WCICA), vol 4, pp 3539–3542. https://doi.org/10.1109/WCICA.2004.1343205

Zhou L, Naim MM, Disney SM (2017) The impact of product returns and remanufacturing uncertainties on the dynamic performance of a multi-echelon closed-loop supply chain. Int J Prod Econ 183:487–502. https://doi.org/10.1016/j.ijpe.2016.07.021

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Stock and flow diagrams and model equations

Model equations

STOCKS

-

1.

Collected products

$$ Collected\ products(t)= collected\ products\left(t- dt\right)+\left( total\ collection\ rate- acce\ rate\ for\ reuse- reje\ rate\ for\ reuse\right)\times dt $$

Inflows

Outflows

-

2.

Components inventory

$$ Components\ inventory\ (t)= components\ inventory\ \left(t- dt\right)+\left( comp\ prdn\ rate+ comp\ reman\ rate+ comp\ acce\ rate\ for\ dir\ reuse- comp\ used\ for\ prdn\right)\times dt $$

Inflows

Outflows

-

3.

Components rejected for direct reuse

$$ comp\ reje\ for\ dir\ reuse\ (t)= comp\ reje\ for\ dir\ reuse\ \left(t- dt\right)+\left( comp\ repla\ rate+ comp\ reje\ rate\ for\ dir\ reuse- recycle\ rate- coomp\ reman\ rate- disposal\ rate\right)\times dt $$

Inflows

Outflows

-

4.

Controllable disposal

$$ controllable\ disposal\ (t)= controllable\ disposal\ \left(t- dt\right)+\left( disposal\ rate\right)\times dt $$

Inflows

-

5.

Distributor orders backlog

$$ distributor\ orders\ backlog\ (t)= distributor\ orders\ backlog\ \left(t- dt\right)+\left( distributor\ orders- distributor\kern0.5em backlog\ red\ rate\right)\times dt $$

Inflows

Outflows

-

6.

Distributor inventory

$$ distributor\ inventory\ (t)= distributor\ inventory\ \left(t- dt\right)+\Big( shipments\ to\ distributor- shipments\ to\ wholesaler\times dt $$

Inflows

Outflows

-

7.

Inventory of components from rejected products

$$ inv\ of\ comp\ from\ reje\ prdcts\ (t)= inv\_ of\_ comp\_ from\_ reje\_ prdcts\left(t- dt\right)+\left( comp\_ from\_ reje\_ prodcts- comp\_ reje\_ rate\_ for\_ dir\_ reuse- comp o\_ acce\_ rate\_ for\_ dir ect\_ reuse\right)\times dt $$

Inflows

Outflows

-

8.

Products for remanufacturing

$$ products\ for\ remn\ (t)= products\ for\ reman\ \left(t- dt\right)+\left( acce\ rate\ for\ reman- reman\ rate- produsctscotremanufactured\right)\times dt $$

Inflows

Outflows

-

9.

Products for cannibalisation

$$ prod\ for\ cannibalisation\ (t)= prod\ for\ cannibalisation\ \left(t- dt\right)+\left( reje\ rate\ for\ reman\right)\times dt $$

Inflows

-

10.

Raw material inventory

$$ raw\ mat\ inventory\ (t)= raw\ mat\ inventory\ \left(t- dt\right)+\left( recycling\ rate- comp\ prod\ rate\right)\times dt $$

Outflows

-

11.

Rejected products for reuse

$$ reje\ prod\ for\ reuse\ (t)= reje\ prod\ for\ reuse\ \left(t- dt\right)+\left( reje\ rate\ for\ prod\ reuse- acce\ rate\ for\ reman- reje\ rate\ for\ reman\right)\times dt $$

Inflows

Outflows

-

12.

Remanufacturing backlogs

$$ remanufacturing\ backlogs\ (t)= remanufacturing\ backlogs\ \left(t- dt\right)+\left( products\ not\ remanufactured\right)\times dt $$

Inflows

-

13.

Retailer orders backlog

$$ retaile{r}^{\prime } s order\ backlog\ (t)= retailer\ orders\ backlog\ \left(t- dt\right)+\left( retaile{r}^{\prime } s order s- retailer\ backlog\ red\ rate\right)\times dt $$

Inflows

Outflows

-

14.

Retailer inventory

$$ retailer\ inventory\ (t)= retailer\ inventory\ \left(t- dt\right)+\left( shipments\ to\ retailer- retail\ sale\right)\times dt $$

Inflows

Outflows

-

15.

Serviceable inventory

$$ serviceable\ inventory(t)= serviceable\ inventory\ \left(t- dt\right)+\left( production\ rate+ reman\ rate+ acce\ prod\ for\ reuse- shipments\ to\ distributor\right)\times dt $$

Inflows

Outflows

-

16.

Wholesaler inventory

$$ wholesaler\ inventory(t)= wholesaler\ inventory\ \left(t- dt\right)+\left( shipments\ to\ wholesaler- shipments\ to\ retailer\right)\times dt $$

Inflows

Outflows

-

17.

Wholesaler orders backlog

$$ wholesaler\ orders\ backlog\ (t)= wholesaler\ orders\ backlog\ \left(t- dt\right)+\left( wholesaler\ orders- wholesaler\ backlog\ redu\ rate\right)\times dt $$

Inflows

Outflows

AUXILLIARY VARIABLES

Rights and permissions

About this article

Cite this article

Tombido, L., Louw, L., van Eeden, J. et al. A system dynamics model for the impact of capacity limits on the Bullwhip effect (BWE) in a closed-loop system with remanufacturing. Jnl Remanufactur 12, 1–45 (2022). https://doi.org/10.1007/s13243-021-00100-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13243-021-00100-7