Abstract

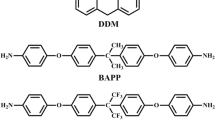

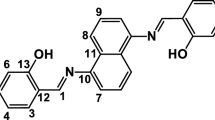

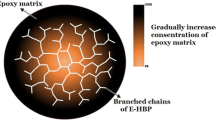

Hydrogenated bisphenol A epoxy resin was cured using different kind of curing agents, resulting in epoxy networks with better shape memory properties than bisphenol A epoxy networks. The non-isothermal curing kinetics investigated by differential scanning calorimetry (DSC) demonstrated that hydrogenated bisphenol A epoxy showed lower curing reactivity than bisphenol A epoxy, while it still could be cured well. The thermal and mechanical properties as well as shape memory properties were studied by dynamic mechanical analysis (DMA), DSC, thermogravimetric analysis (TGA), three-point bending test and U-type shape memory test and cyclic stretch test using DMA. Results manifested that hydrogenated bisphenol A epoxy systems exhibited lower shape transition temperature (lower T g ), slightly higher modulus, better toughness, much faster shape recovery rate, and better elongating ability at temperature above T g than bisphenol A epoxy systems, which was due to the rigidity of cyclohexane ring from its steric hindrance and favorable segmental mobility when absorbing external energy such as heating or bending. Moreover, the shape fixity and shape recovery ratio of all the samples were as high as 96.3~98.5% and 100% and their cycling stability during shape memory test was excellent. Although lower than bisphenol A epoxy networks, hydrogenated bisphenol A epoxy networks possessed high thermal stability with initial degradation temperature (Td5%) of >305 °C.

Similar content being viewed by others

References

Q. Zhao, H. J. Qi, and T. Xie, Prog Polym Sci., 49-50, 79 (2015).

M. D. Hager, S. Bode, C. Weber, and U. S. Schubert, Prog Polym Sci., 49-50, 3 (2015).

Q. Zhao, W. Zou, Y. Luo, and T. Xie, Sci. Adv., 2, 11421 (2016).

Z. Pei, Y. Yang, Q. Chen, Y. Wei, and Y. Ji, Adv. Mater., 28, 156 (2016).

Y. Yang, Z. Pei, Z. Li, Y. Wei, and Y. Ji, J. Am. Chem. Soc., 138, 2118 (2016).

M. I. Lawton, K. R. Tillman, H. S. Mohammed, W. Kuang, D. A. Shipp, and P. T. Mather, ACS Macro Lett., 5, 203 (2016).

R. R. Kohlmeyer, P. R. Buskohl, J. R. Deneault, M. F. Durstock, R. A. Vaia, and J. Chen, Adv. Mater., 26, 8114 (2014).

D. Zhang, Q. Zhang, Y. Lu, J. Jiang, Y. Yao, S. Li, G. L. Liu, and Q. Liu, Nanomedicine, 12, 449 (2016).

Y. Zheng, R. Dong, J. Shen, and S. Guo, ACS. Appl. Mater., 8, 1371 (2016).

Y. C. Chien, W. T. Chuang, U. S. Jeng, and S. H. Hsu, ACS. Appl. Mater., 9, 5419 (2017).

N. Zheng, Z. Fang, W. Zou, Q. Zhao, and T. Xie, Angew Chem. Int. Ed., 55, 11421 (2016).

A. Arnebold and A. Hartwig, Polymer, 83, 40 (2016).

C. Li, J. Y. Dai, X. Q. Liu, Y. H. Jiang, S. Q. Ma, and J. Zhu, Macromol. Chem. Phys., 217, 1439 (2016).

Z. Ma, Y. Wang, J. Zhu, J. Yu, and Z. Hu, J. Polym. Sci., Part A: Polym. Chem., 55, 1790 (2017).

G. Zhang, Q. Zhao, L. Yang, W. Zou, X. Xi, and T. Xie, ACS Macro Lett., 5, 805 (2016).

A. T. Detwiler and A. J. Lesser, J. Mater. Sci., 47, 3493 (2012).

G. C. Psarras, J. Parthenios, and C. Galiotis, J. Mater. Sci., 36, 535 (2001).

T. Xie and I. A. Rousseau, Polymer, 50, 1852 (2009).

C. Liang, C. A. Rogers, and E. Malafeew, J. Intell. Mater. Syst. Struct., 8, 380 (1997).

H. Sun, Y. Liu, H. Tan, and X. Du, J. Appl. Poly. Sci., 131, 39882 (2014).

Z. Wang, W. Song, L. Ke, and Y. Wang, Mater. Lett., 89, 216 (2012).

M. Fan, J. Liu, X. Li, J. Zhang, and J. Cheng, J. Polym. Res., 21, 376 (2014).

N. Zheng, G. Fang, Z. Cao, Q. Zhao, and T. Xie, Polym. Chem., 6, 3046 (2015).

H. Meng and G. Li, Polymer, 54, 2199 (2013).

S. Flint, T. Markle, S. Thompson, and E. Wallace, J. Environ. Manage., 104, 19 (2012).

S. Q. Ma, D. C. Webster, and F. Jabeen, Macromolecules, 49, 3780 (2016).

L. P. Chen, A. F. Yee, J. M. Goetz, and J. Schaefer, Macromolecules, 31, 5371 (1998).

L. P. Chen, A. F. Yee, and E. J. Moskala, Macromolecules, 32, 5944 (1999).

X. Y. Li and A. F. Yee, Macromolecules, 37, 7231 (2004).

J. W. Liu and A. F. Yee, Macromolecules, 31, 7865 (1998).

J. Karger-Kocsis, O. Gryshchuk, and N. Jost, J. Appl. Polym. Sci., 88, 2124 (2003).

K. Wei, G. Zhu, Y. Tang, T. Liu, and J. Xie, J. Mater. Res., 28, 2903 (2013).

K. Wei, G. Zhu, Y. Tang, and L. Niu, J. Polym. Res., 20, 1 (2013).

K. Wei, G. Zhu, Y. Tang, G. Tian, and J. Xie, Smart Mater. Struct., 21, 055022 (2012).

B. Ma, X. Zhou, K. Wei, Y. Bo, and Z. You, Appl. Sci., 7, 523 (2017).

T. T. Li, X. Q. Liu, Y. H. Jiang, S. Q. Ma, and J. Zhu, Iran. Polym. J., 25, 957 (2016).

C. N. C. D. Rosu, F. Mustata, and C. Ciobanu, Thermochim. Acta, 383, 119 (2002).

H. Cai, P. Li, G. Sui, Y. Yu, G. Li, X. Yang, and S. Ryu, Thermochim. Acta, 473, 101 (2008).

C. Wang and C. Lin, J. Appl. Polym. Sci., 74, 1635 (1999).

Q. Wang and W. Shi, Polym. Degrad. Stab., 91, 1747 (2006).

K. O. H. Tobushi and T. Hashimoto, Mech. Mater., 33, 545 (2001).

Y. Liu, K. Gall, M. L. Dunn, A. R. Greenberg, and J. Diani, Int. J. Plast., 22, 279 (2006).

E. R. Abrahamson, M. S. Lake, N. A. Munshi, and K. Gall, J. Intell. Mater. Syst. Struct., 14, 623 (2003).

S. Q. Ma and D. C. Webster, Macromolecules, 48, 7127 (2015).

Y.-C. Chiu, I. C. Chou, W.-C. Tseng, and C.-C. M. Ma, Polym. Degrad. Stab., 93, 668 (2008).

S. Ma, W. Liu, C. Hu, Z. Wang, and C. Tang, Macromol. Res., 18, 392 (2010).

W. Liu, S. Ma, Z. Wang, C. Hu, and C. Tang, Macromol. Res., 18, 853 (2010).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Acknowledgments: The authors are grateful for the financial support from Projects 51473180, 51773216 supported by the National Natural Science Foundation of China, and Chinese MIIT Special Research Plan on Civil Aircraft, grant No. MJ-2015-H-G-103.

Rights and permissions

About this article

Cite this article

Wei, J., Ma, S., Yue, H. et al. Comparison of Hydrogenated Bisphenol A and Bisphenol A Epoxies: Curing Behavior, Thermal and Mechanical Properties, Shape Memory Properties. Macromol. Res. 26, 529–538 (2018). https://doi.org/10.1007/s13233-018-6075-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-018-6075-3