Abstract

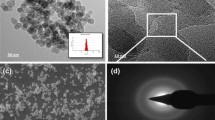

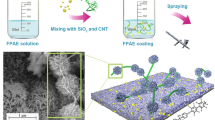

A superhydrophobic surface with excellent chemical stability was fabricated using the spraying method, one of the most efficient technologies for producing large-area coatings at low cost. Poly(vinylidene fluoride) (PVDF) was used as a hydrophobic polymer material, and heptadecafluoro-1,1,2,2,-tetra-hydrodecyl)trichlorosilane (FTS), which reacts with moisture during curing, was used to improve the water repellency and durability. Spray coating of PVDF alone yielded PVDF nanostructures described by the Cassie-Baxter model. The water contact angle of a water droplet on this surface, however, was 128°, indicating that the surface was not superhydrophobic. On the other hand, spray-coating a mixed PVDF-FTS solution provided a complex and homogeneous nanostructured surface with excellent water repellency and a contact angle of up to 159°. Immersion of the PVDF-only film for 20 min in N,N-dimethylformamide (DMF), a good solvent for PVDF, led to complete dissolution of the film. By contrast, the PVDF-FTS film maintained its superhydrophobicity with a water contact angle of 151° after 20 min of immersion in DMF, and still exhibited a high contact angle of 142° after 1 h. The PVDF-FTS film developed in the present work should enable the production of large-area superhydrophobic coatings at low cost using a simple spray process. Moreover, the PVDF-FTS film displayed excellent stability against solvents, thus increasing its suitability for robust superhydrophobic applications.

Similar content being viewed by others

References

W.-L. Min, B. Jiang, and P. Jiang, Adv. Mater., 20, 3914 (2008).

K. Liu, X. Yao, and L. Jiang, Chem. Soc. Rev., 39, 3240 (2010).

J. Li, L. Yan, Q. Ouyang, F. Zha, Z. Jing, X. Li, and Z. Lei, Chem. Eng. J., 246, 238 (2014).

Y. Wang, J. Xue, Q. Wang, Q. Chen, and J. Ding, ACS Appl. Mater. Interfaces, 5, 3370 (2013).

S. Zhang, F. Lu, L. Tao, N. Liu, C. Gao, L. Feng, and Y. Wei, ACS Appl. Mater. Interfaces, 5, 11971 (2013).

X. Feng and L. Jiang, Adv. Mater., 18, 3063 (2006).

J. Ou, W. Hu, S. Liu, M. Xue, F. Wang, and W. Li, ACS Appl. Mater. Interfaces, 5, 3101 (2013).

H. Ogihara, J. Xie, J. Okagaki, and T. Saji, Langmuir, 28, 4605 (2012).

Z. Guo, W. Liu, and B.-L. Su, J. Colloid Interface Sci., 353, 335 (2011).

G. Mao-Gang, X. Xiao-Liang, Y. Zhou, L. Yan-Song, and L. Ling, Chin. Phys. B, 19, 056701 (2010).

D.-H. Kim, Y. Kim, B. M. Kim, J. S. Ko, C.-R. Cho, and J.-M. Kim, J. Micromech. Microeng., 21, 045003 (2011).

T.-Y. Kim, B. Ingmar, K. Bewilogua, K. H. Oh, K.-R. Lee, Chem. Phys. Lett., 436, 199 (2007).

W. Ming, D. Wu, R. V. Benthem, and G. D. With, Nano Lett., 5, 2298 (2005).

D. Kim, J. Kim, H. C. Park, K.-H. Lee, and W. Hwang, J. Micromech. Microeng., 18, 015019 (2008).

R. N. Wenzel, Ind. Eng. Chem., 28, 988 (1936).

L. Cao, H.-H. Hu, and D. Gao, Langmuir, 23, 4310 (2007).

A. B. D. Cassie and S. Baxter, Trans. Faraday Soc., 40, 546 (1944).

A. Marmur and E. Bittoun, Langmuir, 25, 1277 (2009).

M. Ma, M. Gupta, Z. Li, L. Zhai, K. K. Gleason, R. E. Cohen, M. F. Rubner, and G. C. Rutledge, Adv. Mater., 19, 255 (2007).

D. Han and A. J. Steckl, Langmuir, 25, 9454 (2009).

Y. Zhao, Z. Xu, X. Wang, and T. Lin, Appl. Surface Sci., 286, 364 (2013).

K. Manabe, K. Manabe, S. Nishizawa, K.-H. Kyung, and S. Shiratori, ACS Appl. Mater. Interfaces, 6, 13985 (2014).

Y. H. Sung, Y. D. Kim, H.-J. Choi, R. Shin, S. Kang, and H. Lee, Appl. Surface Sci., 349, 169 (2015).

T. Li, M. Paliy, X. Wang, B. Kobe, W.-M. Lau, and J. Yang, ACS Appl. Mater. Interfaces, 7, 10988 (2015).

N. Kawasegi, N. Morita, S. Yamada, N. Takano, T. Oyama, S. Momota, J. Taniguchi, and I. Miyamoto, Appl. Surface Sci., 253, 3284 (2007).

N. Miljkovic, R. Enright, and E. N. Wang, ACS Nano, 6, 1776 (2012).

N. A. Azarova, J. W. Owen, C. A. McLellan, M. A. Grimminger, Eric. K. Chapman, J. E. Anthony, and O. D. Jurchescu, Org. Electron., 11, 1960 (2010).

D. Vak, S.-S. Kim, J. Jo, S.-H. Oh, S.-I. Na, J. Kim, and D.-Y. Kim, Appl. Phys. Lett., 91, 081 (2007).

Y. Zhang, D. Ge, and S. Yang, J. Colloid Interface Sci., 423, 101 (2014).

J. Li, R. Wu, Z. Jing, L. Yan, F. Zhan, and Z. Lei, Langmuir, 31, 10702 (2015).

Y. Li, S. Chen, M. Wu, and J. Sun, Adv. Mater., 26, 3344 (2014).

P. A. Levkin, F. Svec, and J. M. J. Fréchet, Adv. Funct. Mater., 19, 1993 (2009).

D. L. Gilmore, R. C. Dykhuizen, R. A. Neiser, T. J. Roemer, and M. F. Smith, J. Therm. Spray Technol., 8, 576 (1999).

T. Stoltenhoff, H. Kreye, and H. J. Richter, J. Therm. Spray Technol., 11, 542 (2002).

L. Xu, R. G. Karunakaran, J. Guo, and S. Yang, ACS Appl. Mater. Interfaces, 4, 1118 (2012).

M. G. Hankins, P. J. Resnick, P. J. Clews, T. M. Mayer, D. R. Wheeler, D. M. Tanner, and R. A. Plass, Proc. SPIE, 4980, 238.

R. W. P. Fairbank and M. J. Wirth, J. Chromatogr. A, 830, 285 (1999).

S. Park, K.-S. Lee, G. Bozoklu, W. Cal, S. T. Nguyen, and R. S. Ruoff, ACS Nano, 2, 572 (2008).

P. Xu, H. Tang, S. Li, J. Ren, E. V. Kirk, W. J. Murdoch, M. Radosz, and Y. Shen, Biomacromolecules, 5, 1736 (2004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Acknowledgment: This work was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2016R1D1A1B03936094).

Rights and permissions

About this article

Cite this article

Jeong, H., Baek, S., Han, S. et al. Chemically Robust Superhydrophobic Poly(vinylidene fluoride) Films with Grafting Crosslinkable Fluorinated Silane. Macromol. Res. 26, 493–499 (2018). https://doi.org/10.1007/s13233-018-6072-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-018-6072-6