Abstract

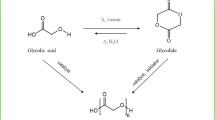

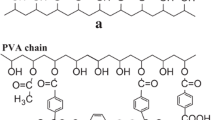

The current study deals with the synthesis of various compositions of crosslinked poly(ester-urethane-acrylate) (PEUA)/methylmethacrylate (MMA) copolymer employing free radical polymerization. Initially, (1,4-butanediol) orthophthalate (BPE) polyester polyol has been synthesized by reacting 1,4 butanediol (BDO) and phthalic anhydride (PA). Subsequently the PEUA prepolymer was formed by reacting one mole of BPE with two mole of isophorone diisocyanate (IPDI) followed by end capping with two mole of 2-hydroxyethyl methacrylate (HEMA) in the presence of dibutyltin dilaurate (DBTL) catalyst. Finally, different compositions of crosslinked PEUA/MMA copolymer were prepared by reacting the PEUA prepolymer with MMA, in the presence of 1% azobisisobutyronitrile (AIBN) (w/w) as a chain initiator. The formation of BPE, PEUA and copolymers was confirmed by Fourier transform infrared (FT-IR) and 1H NMR spectroscopy. Water uptake, mechanical, thermal and optical properties of PEUA, PMMA and their copolymers have been also investigated. The impact fractured surface morphology of copolymers was observed using scanning electron microscope (SEM). The results showed that the increased miscibility, improved mechanical and physical properties of copolymer was influenced by the crosslink density. Dynamic mechanical analysis (DMA), thermogravimetric analysis (TGA), Haze and transparency of PEUA/MMAcopolymers were determined. The copolymer with 40 wt% MMA loading exhibited optimum mechanical and physical properties with respect to the other compositions.

Similar content being viewed by others

References

L. Gao, L. Zhou, S. Fang, C. Wu, L. Guo, G. Sun, and S. Ma, J. Polym. Res., 18, 833 (2011).

D. H. Park, J. K. Oh, S. B. Kim, and W. N. Kim, Macromol. Res., 21, 1247 (2013).

S. W. Lee, Y. H. Lee, H. Park, and H. D. Kim, Macromol. Res., 21, 709 (2013).

Y. C. Chung, H. Y. Kim, J. W. Choi, and B. C. Chun, Macromol. Res., 22, 1115 (2014).

M. L. Digar, S. L. Hung, T. C. Wen, and A. Gopalan, Polymer, 43, 1615 (2002).

Y. H. Lin, K. H. Liao, N. K. Chou, S. S. Wang, S. H. Chu, and K. H. Hsieh, Eur. Polym. J., 44, 2927 (2008).

M. Manju, M. K. Veeraiah, S. Prasannakumar, N. M. Gowda, and B. S. Sherigara, Am. J. Polym. Sci., 2, 22 (2012).

P. Santhana Gopala Krishnan, V. Choudhary, and I. K. Varma, J. Appl. Polym. Sci., 48, 1015 (1993).

S. Velankar, J. Pazos, and S. L. Cooper, J. Appl. Polym. Sci., 62, 1361 (1996).

J. Skrzypek, J. Z. Sadłowski, M. Lachowska, and M. Turzański, Chem. Eng. Process. Process Intensif., 33, 413 (1994).

S. Guo, S. Zhou, H. Li, and B. You, J. Colloid Interface Sci., 448, 123 (2015).

R. Ballestero, B. M. Sundaram, H. V. Tippur, and M. L. Auad, Express Polym. Lett., 10, 204 (2016).

M. R. Patel, J. M. Shukla, N. K. Patel, and K. H. Patel, Mater. Res., 12, 385 (2009).

O. Coutelier, M. El Ezzi, M. Destarac, F. Bonnette, T. Kato, A. Baceiredo, and D. Taton, Polym. Chem., 3, 605 (2012).

O. R. Pardini and J. I. Amalvy, J. Appl. Polym. Sci., 107, 1207 (2008).

N. B. Colthup, L. H. Daly, and S. E. Wiberley, Introduction to Infrared and Raman Spectroscopy, Academic Press, New York, 1975.

H. S. Suh, J. Y. Ha, J. H. Yoon, C. S. Ha, H. Suh, and I. Kim, React. Funct. Polym., 70, 288 (2010).

M. Sultan, H. N. Bhatti, M. Zuber, and M. Barikani, Korean J. Chem. Eng., 30, 488 (2013).

A. Bahadur, M. Shoaib, A. Saeed, and S. Iqbal, e-Polymers, 16, 463 (2016).

J. Huang and L. Zhang, Polymer, 43, 2287 (2002).

S. D. Maurya, M. Purushothaman, P. S. G. Krishnan, and S. K. Nayak, J. Thermoplast. Compos. Mater., 0892705712475011 (2013).

A. K. Tyagi, V. Choudhary, and I. K. Varma, Eur. Polym. J., 30, 919 (1994).

Y. D. Ma, T. Fukuda, and H. Inagaki, Polym. J., 15, 673 (1983).

T. Zhang, W. Wu, X. Wang, and Y. Mu, Prog. Org. Coat., 68, 201 (2010).

M. Zuber, S. A. A. Shah, T. Jamil, and M. I. Asghar, Int. J. Biol. Macromol., 67, 254 (2014).

J. L. Zhang, D. M. Wu, D. Y. Yang, and F. X. Qiu, J. Polym. Environ., 18, 128 (2010).

K. P. Mahesh, M. Alagar, and S. A. Kumar, Polym. Adv. Technol., 14, 137 (2003).

D. Jehl, J. M. Widmaier, and G. C. Meyer, Eur. Polym. J., 19, 597 (1983).

M. H. Gutierrez-Villarreal, and J. Rodríguez-Velazquez, J. Appl. Polym. Sci., 105, 2370 (2007).

X. Hu and R. J. Young, Plast. Rubber Process. Appl., 12, 113 (1989).

W. J. Lee, E. S. Kuo, C. Y. Chao, and Y. P. Kao, Holzforschung, 69, 547 (2015).

S. Tasic, B. Bozic, and B. Dunjic, Prog. Org. Coat., 51, 320 (2004).

B. Dunjic, S. Tasic, and B. B. ic, Eur. Coatings J., 6, 36 (2004).

R. Chen, C. Zhang, and M. R. Kessler, RSC Adv., 4, 35476 (2014).

L. J. Chen, Q. L. Tai, L. Song, W. Y. Xing, G. X. Jie, and Y. Hu, Express Polym. Lett., 4, 53 (2010).

D. Kunwong, N. Sumanochitraporn, and S. Kaewpirom, Sonklanakarin J. Sci. Technol., 33, 201 (2011).

M. Liu, C. Chen, W. X. Li, X. Zhu, S. Li, and C. L. Zheng, e-Polymers, 17, 31 (2017).

M. M. Eldin, M. R. Elaassar, A. A. Elzatahry, and M. M. B. Al-Sabah, Arabian J. Chemistry, doi: 10.1016/j.arabjc.2014.10.037 (2014).

S. Qiu, S. Li, Y. Tao, X. Feng, B. Yu, X. Mu, and G. Jie, RSC Adv., 5, 73775 (2015).

S. N. Tripathi, P. Saini, D. Gupta, and V. Choudhary, J. Mater. Sci., 48, 6223 (2013).

N. Fu, G. Li, Q. Zhang, N. Wang, and X. Qu, RSC Adv., 4, 1067 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Acknowledgments: Financial support given by the, Department of Chemicals and Petrochemicals, Ministry of Chemical & Fertilisers, Govt. of INDIA (Letter No. 15012/1/2013-PC-I) is gratefully acknowledged.

Rights and permissions

About this article

Cite this article

Maurya, S.D., Kurmvanshi, S.K., Mohanty, S. et al. Synthesis and characterization of crosslinked transparent poly(ester-urethane-acrylate) containing methyl methacrylate. Macromol. Res. 25, 871–881 (2017). https://doi.org/10.1007/s13233-017-5105-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-017-5105-x